Bipolar grinding wheel electric spark grinding machining device and method suitable for insulating hard and brittle materials

A grinding technology for hard and brittle materials, which is applied in the field of special processing, can solve the problems of difficult-to-machine insulating hard and brittle materials, and achieve the effect of simple structure and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

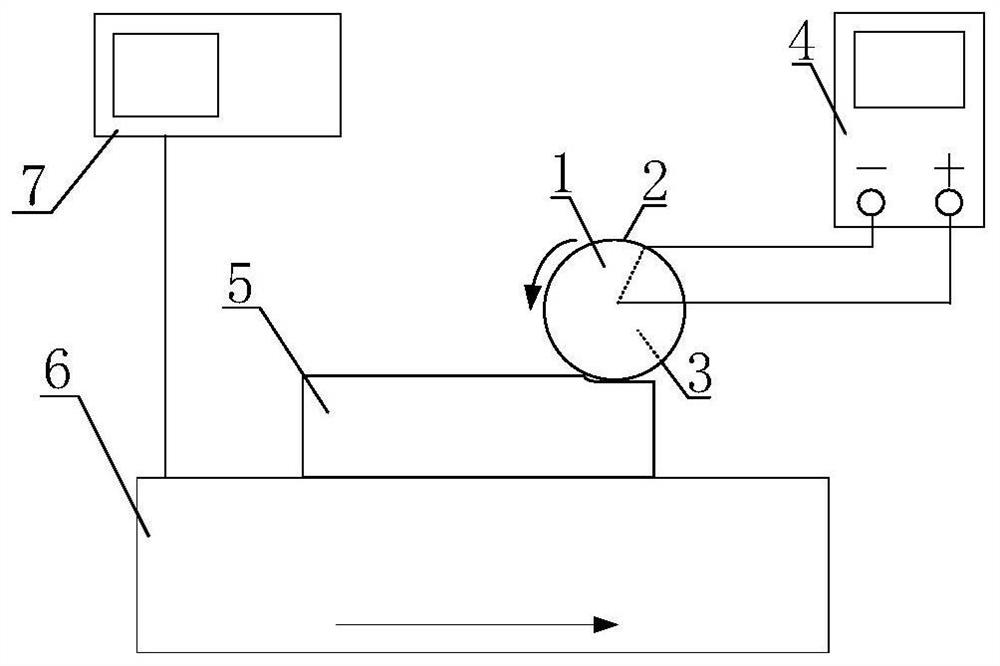

[0044] Such as figure 1 As shown, an EDM processing device suitable for bipolar grinding wheels for insulating hard and brittle materials includes a bipolar grinding wheel, a power supply 4 , workpieces to be processed 5 , a numerical control system 7 , and a workbench 6 . Place the workpiece 5 to be processed on the workbench 6, connect the workbench 6 to the numerical control system 7, and adjust the position of the workbench 6 through the numerical control system 7, so that the workpiece 5 to be processed is located directly in front of the bipolar grinding wheel. The power supply 4 is a pulse power supply for EDM.

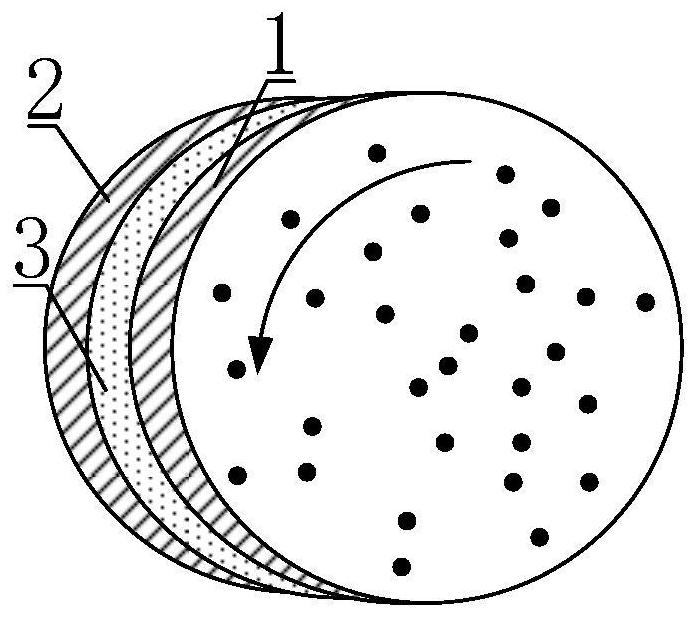

[0045] Such as figure 2 As shown, the bipolar grinding wheel is composed of polar grinding wheel I1, polar grinding wheel II2 and insulating medium layer 3. The polar grinding wheel I1 and the polar grinding wheel II2 are fixed together by an insulating medium layer 3 to form a bipolar grinding wheel. The polar grinding wheel I1 is connected to the negative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com