Automatic metal machining machine with electromechanical high-temperature molding and low-temperature vacuum cooling functions

A low-temperature vacuum and metal processing technology, applied in metal processing equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of inability to form a continuous and reliable processing structure, reduce processing efficiency, and cumbersome and laborious operations, so as to improve processing efficiency , Convenient feeding and retrieving operation, simple and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

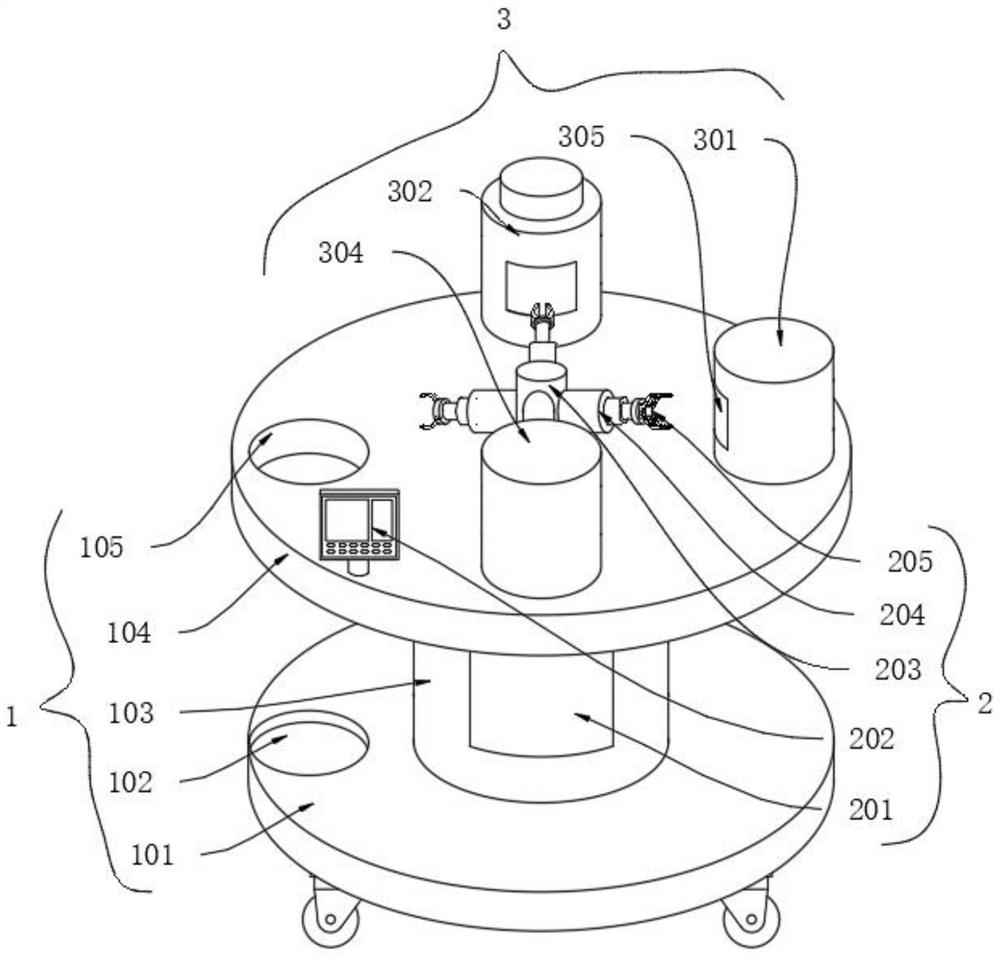

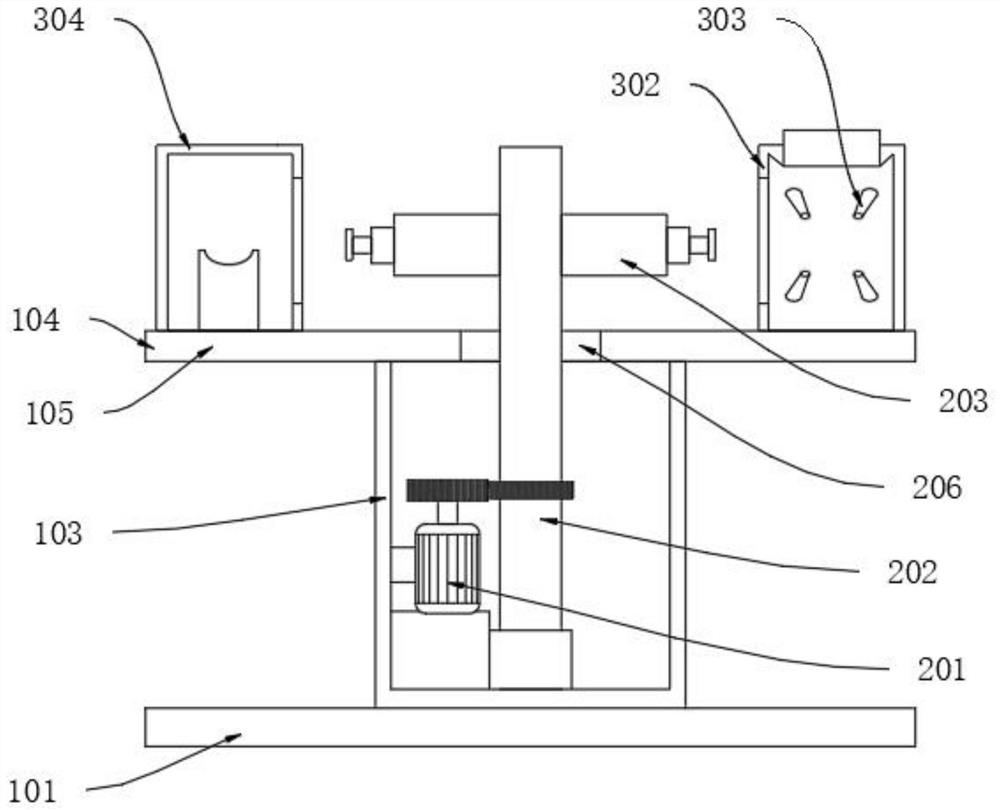

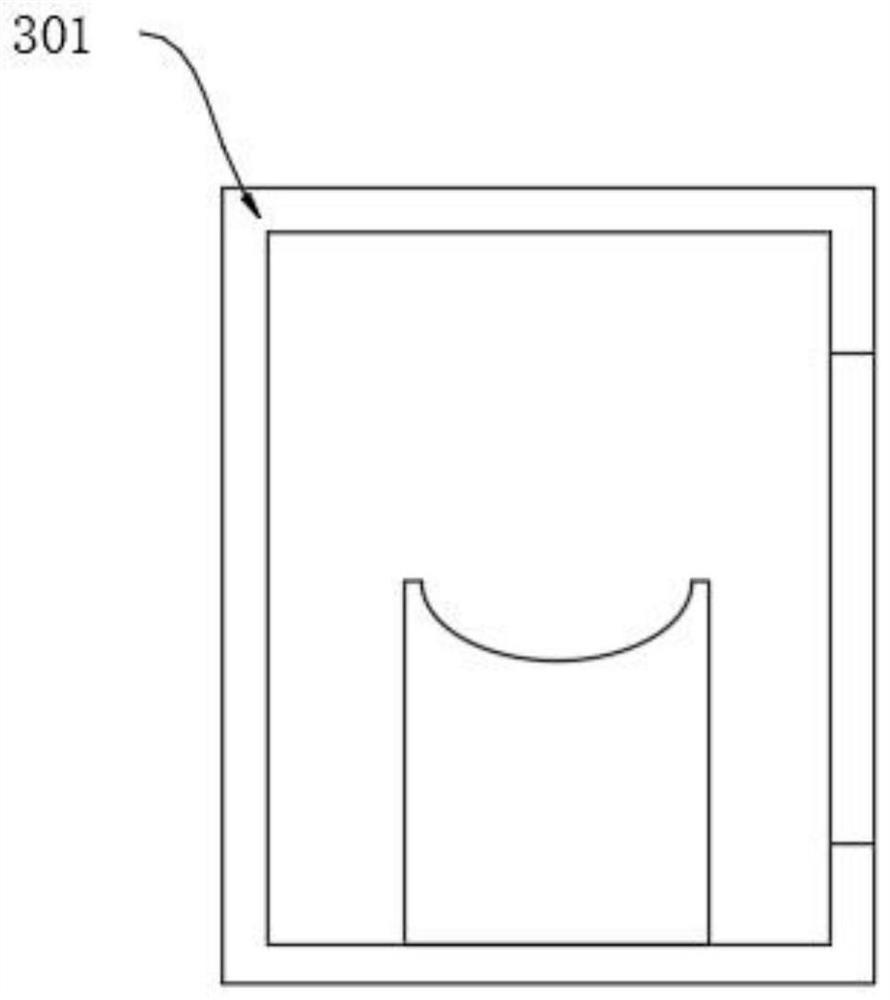

[0024] see Figure 1-4 According to an embodiment of the present invention, an automatic metal processing machine with electromechanical high-temperature molding and low-temperature vacuum cooling includes a main body mechanism 1, a support base plate 101, a material receiving trough 102, a support cylinder 103, a workbench 104, a discharge port 105, a power Mechanism 2, driving mechanism 201, control mechanism 202, rotating pole 203, telescopic mechanism 204, gripper 205, sensor 206, station mechanism 3, high temperature plastic box 301, welding box 302, welding gun head 303, low temperature vacuum Cooling box 304, material inlet and outlet 305.

[0025] Specifically, such as figure 1 and figure 2 as well as image 3 and Figure 4 As shown, it includes a main body mechanism 1, a power mechanism 2 is installed on one side of the main body mechanism 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com