Metal propeller shot-blasting repairing device

A blade and metal technology, applied in the field of helicopter metal blade maintenance, can solve the problems of unqualified product repair, high labor intensity, and complicated operation, and achieve the effects of reliable use, improved production efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

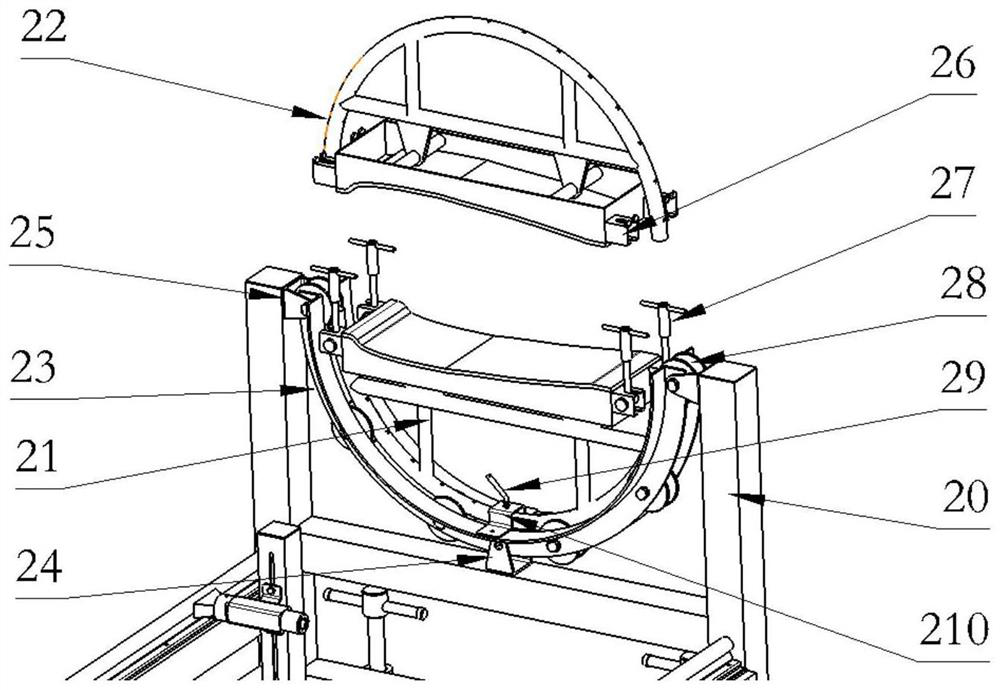

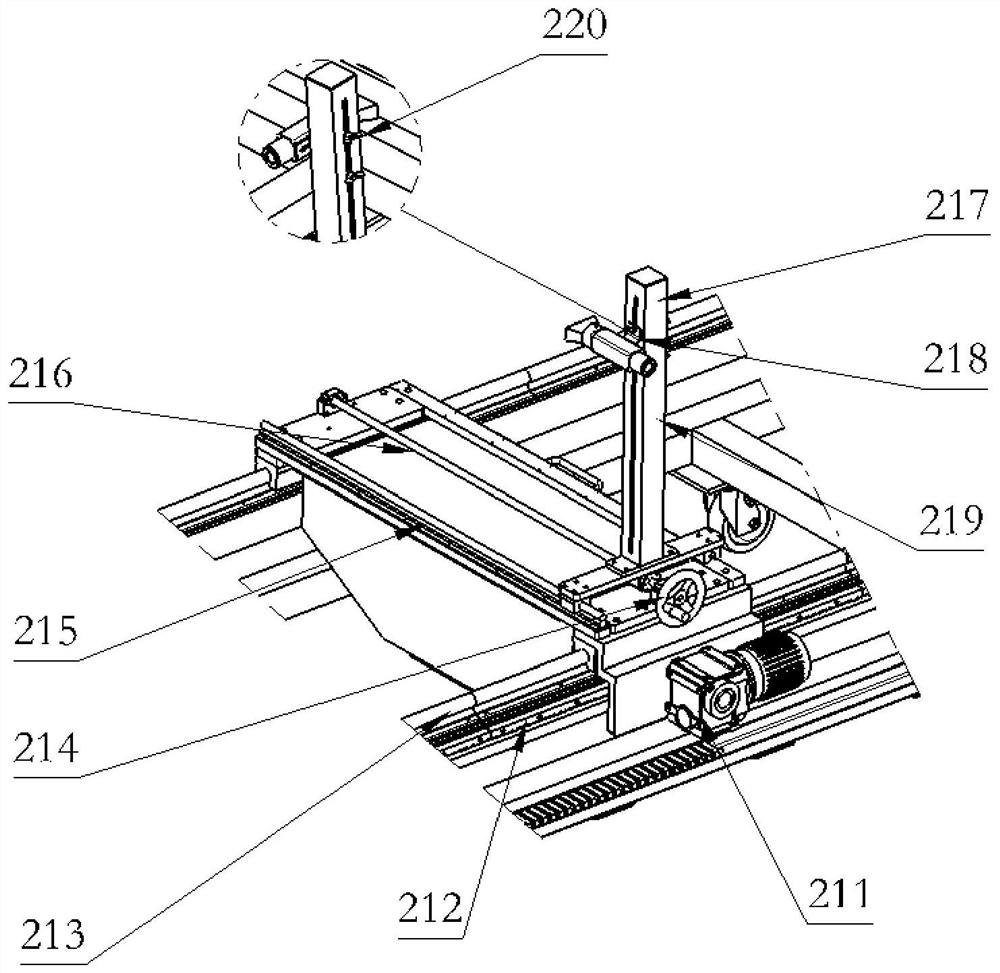

[0034] The invention provides a metal paddle girder repairing shot peening tool, which can quickly adjust the placement of the paddle by rotating the angle of the paddle, so that the surface that needs to be repaired faces the working surface for easy operation; the support can be adjusted quickly through the spray gun The position of the spray gun makes the shot blasting outlet quickly align with the position that needs to be repaired; the automatic feed can be realized by operating the electric control button, and the feeding speed of the shot peening can be precisely controlled; the shot material required for a single repair can be stored.

[0035] The purpose of the present invention is to change the existing operation mode and provide a shot blasting device capable of rapid adjustment, convenient operation, reliable use and greatly improved production efficiency.

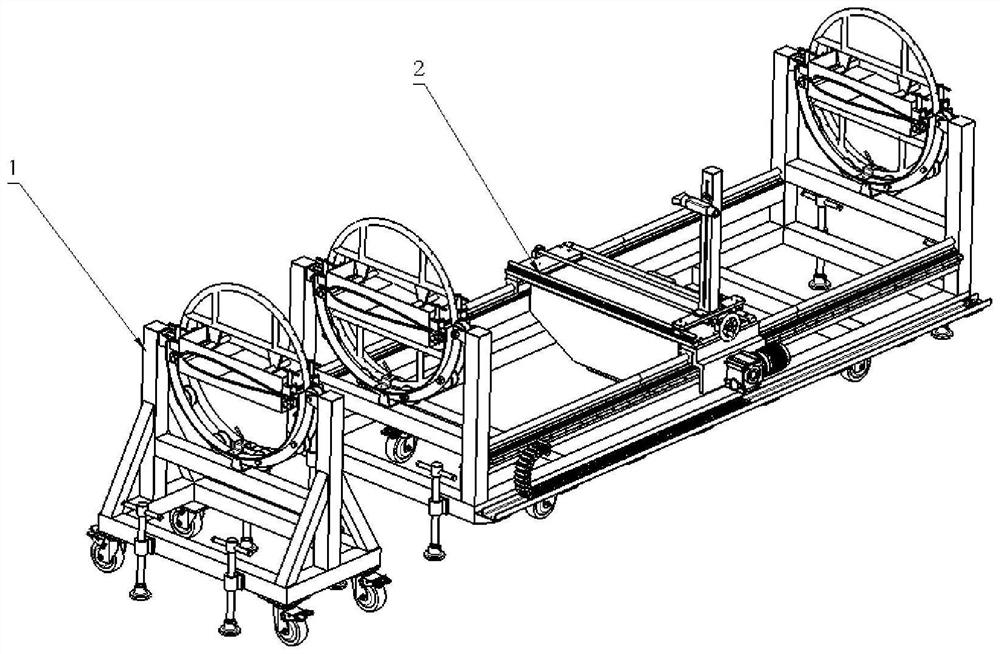

[0036] see Figure 1-4 , the above device is mainly composed of two parts (such as figure 1 Shown): supplem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com