Finite element mesh generation method for honeycomb sandwich panel with pit defects

A pit defect and grid generation technology, applied in image data processing, 3D modeling, instruments, etc., can solve problems such as surface core desoldering, and achieve the effect of improving modeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

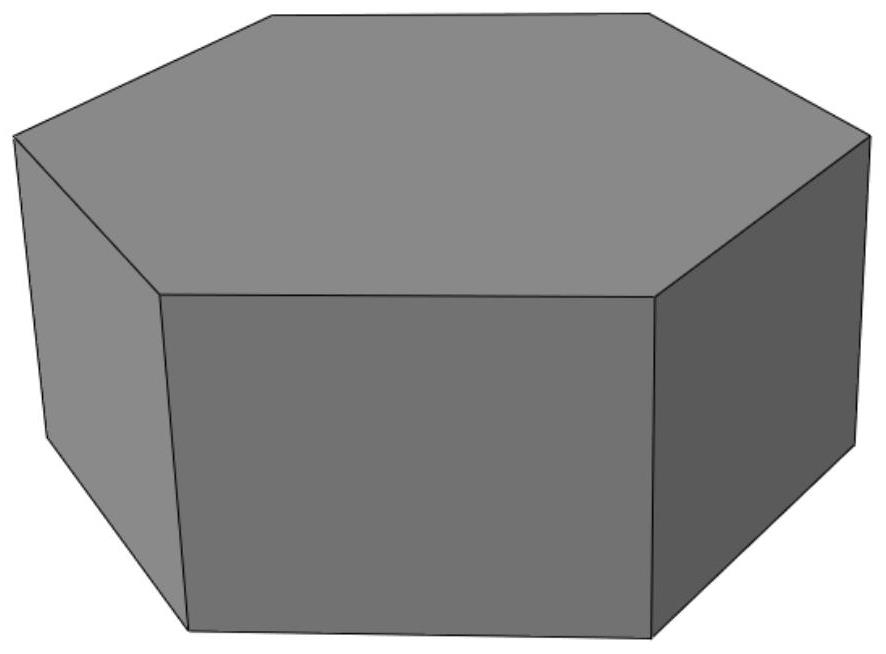

[0032] Suppose the main dimensions of a honeycomb sandwich panel with pit defects are: the total length L is 150mm, the total width W is 60mm, the total height H is 8mm, and the honeycomb side length is l 0 8.66mm, cell height h 07mm, grid seed number n 0 6, pit diameter d 0 30mm, pit depth d 1 1mm.

[0033] S1. Calculate the number of honeycombs in the length and width direction of the honeycomb sandwich panel;

[0034] Calculation (L-2l 0 ) / (3l 0 ) and rounded to get n x =5, then the number of cells in the longitudinal direction is 2n x +1=11; calculate and rounded to get n y =4, the number of cells in the width direction is 4.

[0035] S2. Construct the geometric model of various components of the honeycomb sandwich panel;

[0036] Decompose the honeycomb sandwich panel into three basic components, which are right tria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com