Flame resistant fabrics

A fabric and fabric weaving technology, applied in the direction of fabrics, textiles, textiles, and papermaking, can solve problems such as roughness, expensive touch, and fabrics that cannot compete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

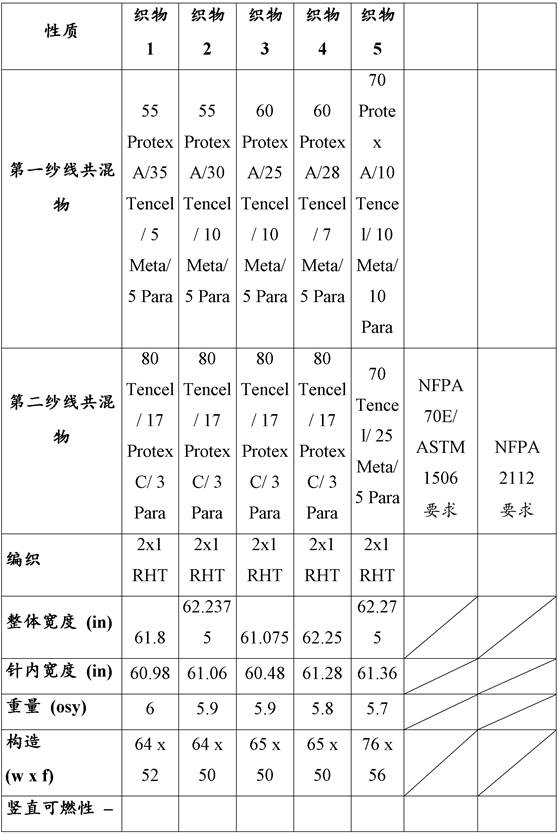

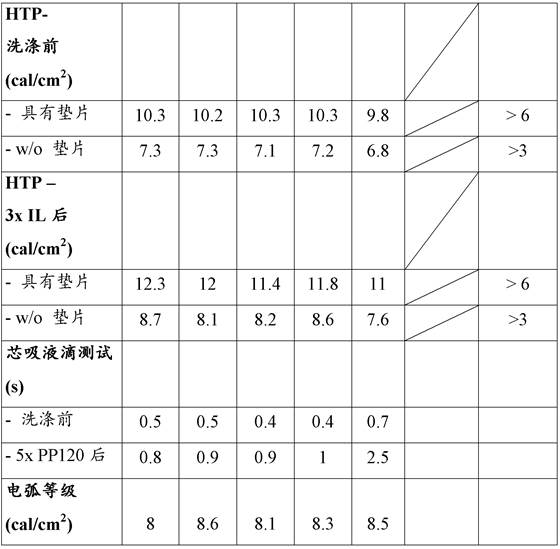

Embodiment 1

[0071] Embodiment 1. A fabric formed from a first yarn and a second yarn, wherein the fabric has a first side and a second side opposite the first side, and wherein: the first yarn comprises a second side A fiber blend, the first fiber blend comprising aramid fiber, modacrylic fiber and cellulose fiber; the aramid fiber and modacrylic fiber of the first fiber blend acrylonitrile fibers comprise at least 50% of said first fiber blend; said first fiber blend comprises more modacrylic fibers than aramid fibers; said second yarn comprises Two fiber blends, the second fiber blend being different from the first fiber blend and comprising aramid fibers, modacrylic fibers, and cellulose fibers; the second fiber blend The fabric comprises at least 60% cellulose fibers; the second fiber blend comprises more modacrylic fibers than aramid fibers; the first yarns are primarily exposed on the first side of the fabric above; the second yarn is primarily exposed on the second side of the fab...

Embodiment 2

[0072] Embodiment 2. The fabric of any preceding or subsequent embodiment or combination of embodiments, wherein the aramid fibers and modacrylic fibers of the first fiber blend comprise the first fibers At least 60% of the blend.

Embodiment 3

[0073] Embodiment 3. The fabric of any preceding or following embodiment or combination of embodiments, wherein the first fiber blend comprises modacrylic fibers up to twice as many polyaramid fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com