Compact jet dispensing valve with adjustable glue discharge amount and glue spraying method of compact jet dispensing valve

A compact, high-volume glue technology, applied to the surface coating liquid device, coating, etc., can solve the problems of difficult adjustment of glue output, small glue injection, limited material deformation, etc., to ensure the working life and motion stability, improve work efficiency, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

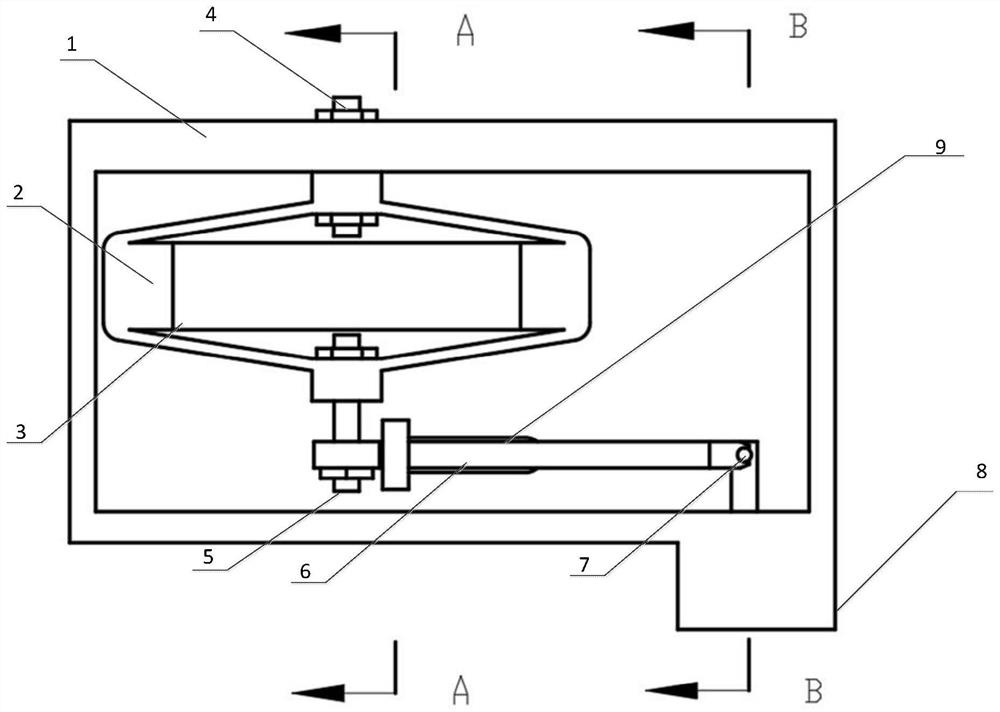

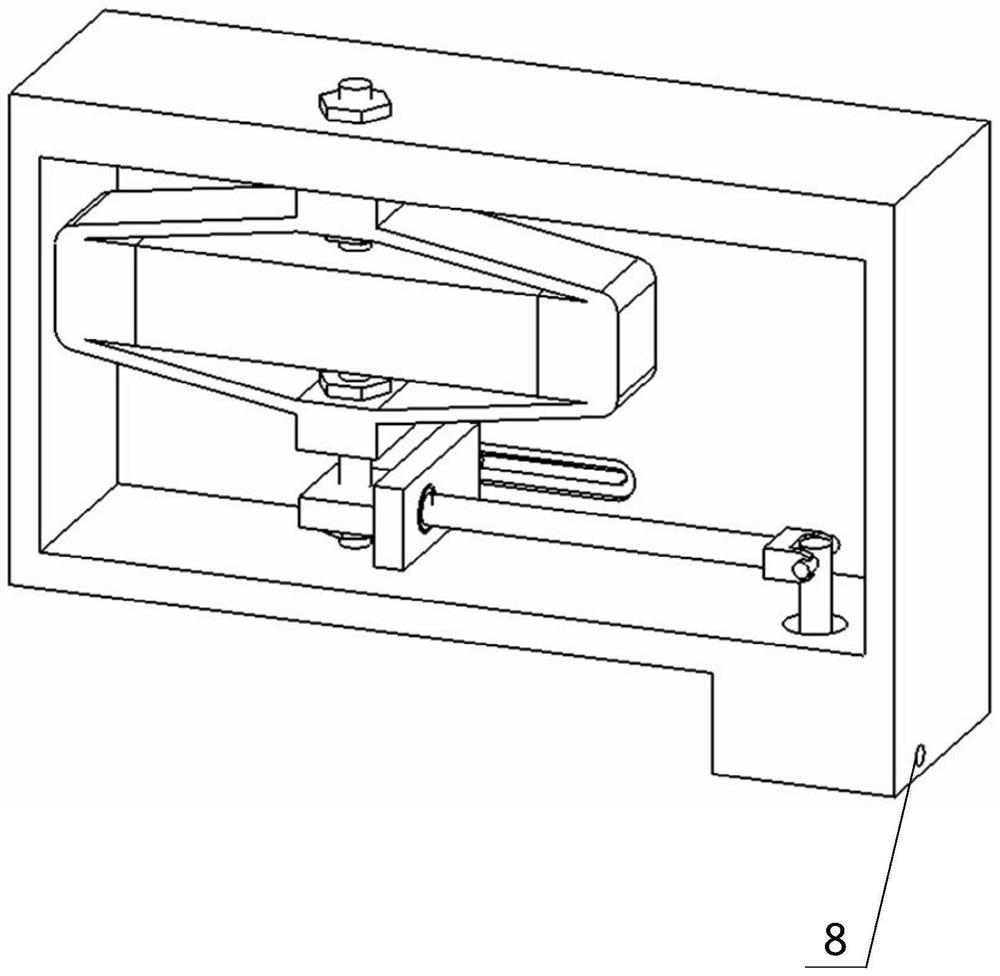

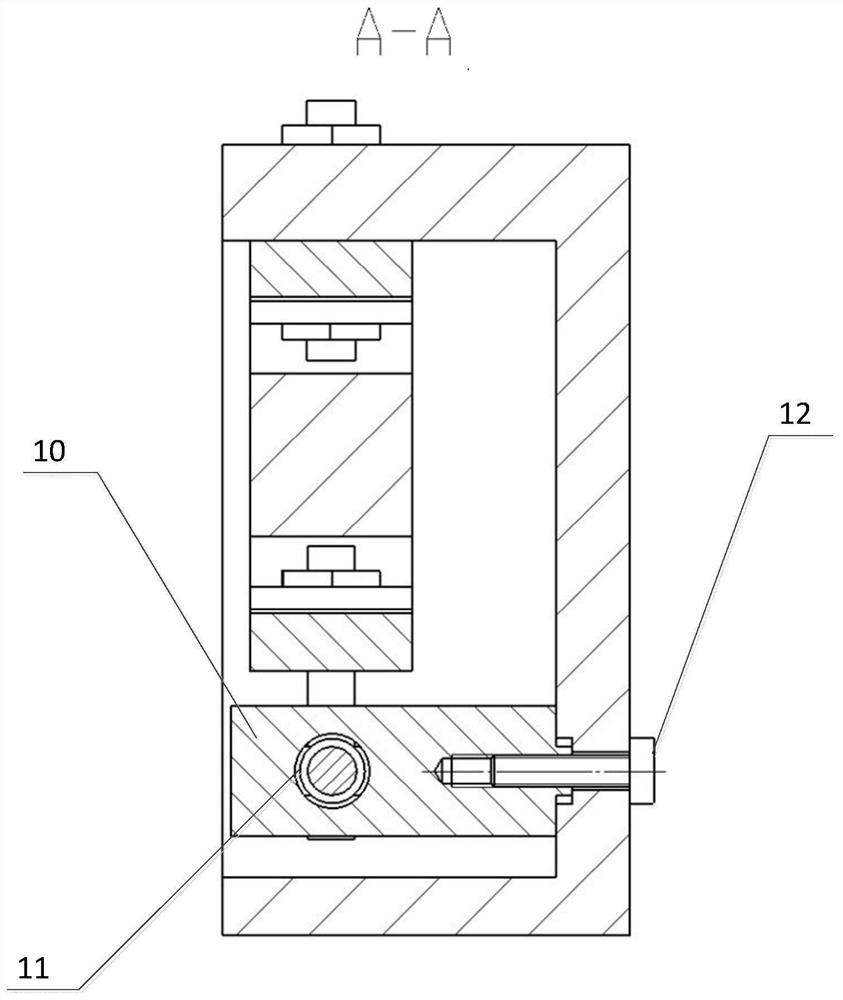

[0029] Such as figure 1 , 2 As shown in and 3, a compact jet dispensing valve with adjustable glue output includes a dispensing valve housing 1, a primary displacement amplifying mechanism, a secondary displacement amplifying mechanism and a striker assembly; the primary displacement amplifying mechanism includes a piezoelectric The ceramic actuator 3 and the hollow flexible ring 2; the piezoelectric ceramic actuator 3 is arranged horizontally, and the two ends are respectively fixed to the two inner walls of the hollow flexible ring 2; the top of the hollow flexible ring 2 is fixed to the dispensing valve housing 1 The secondary displacement amplification mechanism includes a connecting lever 6, a bearing frame with arms 10 and a spherical ball b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com