Multi-angle swing type automatic welding machine for electrical engineering

An automatic welding machine and electrical engineering technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of insufficient welding accuracy of workpieces, time-consuming and laborious, and improve welding efficiency and accuracy. The effect of clamping and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

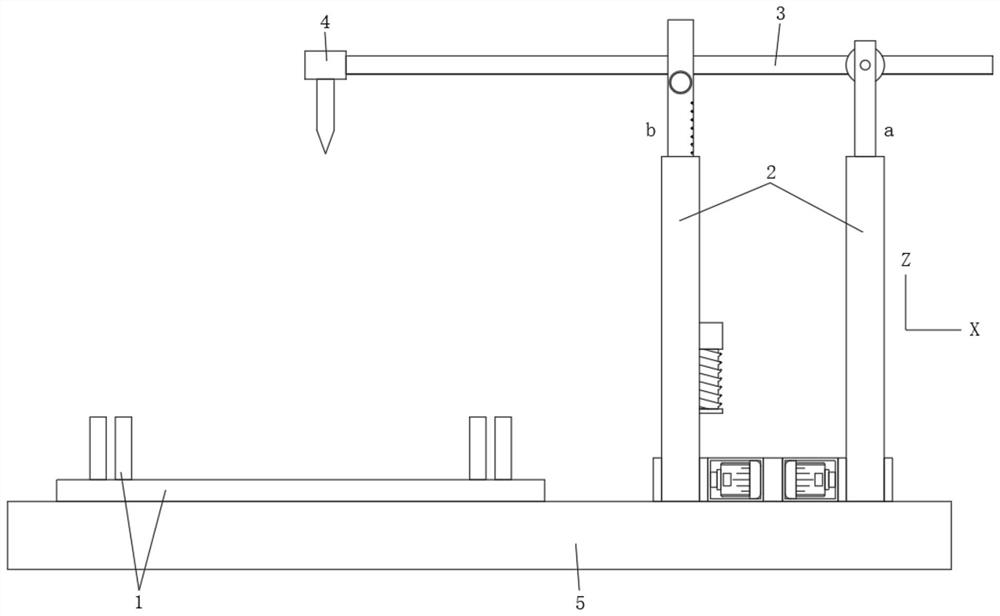

[0059] In the first embodiment, the Z-axis rising assembly 2 includes:

[0060] The first outer lever 201;

[0061] The electric lifting rod 202 is disposed inside the first outer lever 201, the top of the electric lifting rod 202 through the first outer lever 201, and the cross-frame 3 penetrates the telescopic end fitted to the electric lifting rod 202.

[0062] From the above, in the first embodiment, automatic lifting is achieved by the driving of the electric rod 202.

Embodiment approach 2

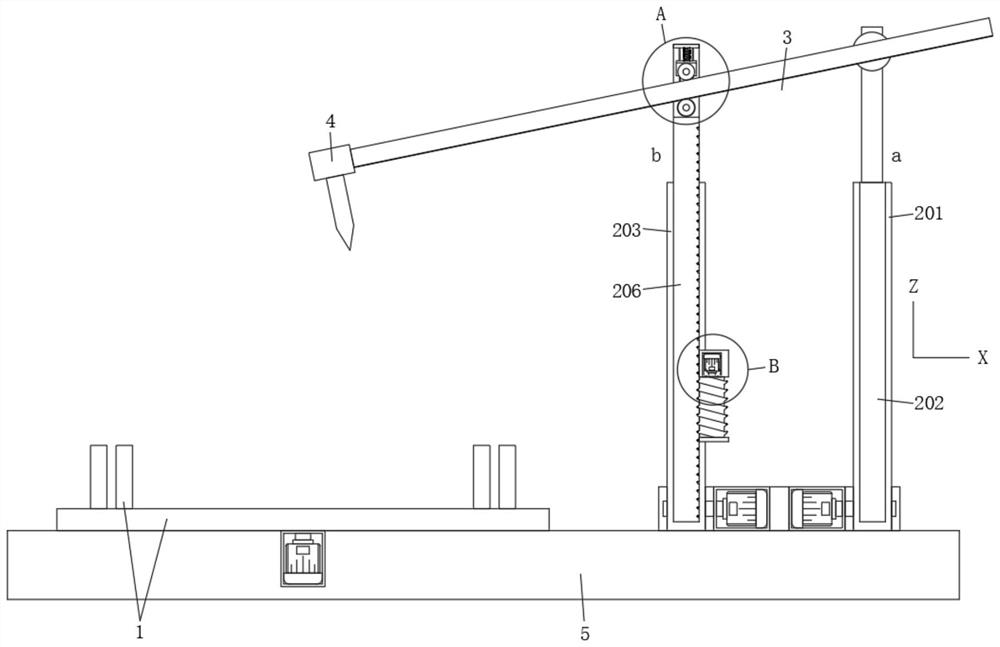

[0063] In the second embodiment, the Z-axis rising and lower assembly 2 includes:

[0064] The second outer lever 203; there is a mounting groove on one side of the second outer lever 203, and two mount 204 is fixed to the mounting groove symmetry, and one of the mount 204 is provided with a rotating motor in two mount 204. A threaded rod 205 that can be rotated around the Y axis is connected between the thread, and the threaded rod 205 is rotated by rotating the motor;

[0065] The lifting inner rod 206 is slidably in the second outer lever 203 along the Z axis, and a threaded groove is opened on one side of the lifting inner rod 206, and the threaded rod 205 is spiiled to the lifting inner rod 206 through the threaded groove.

[0066] From the above, in the second embodiment, the thread rod 205 is generated between the thread rod 205 and the rod 205 and the lifting inner rod 206, thereby effectively driving the lifting inner rod 206 moves along the Z axis, and effectively realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com