Manufacturing process of plastic-dripping vamp

A production process and technology for shoe uppers, which are applied to household components, household appliances, other household appliances, etc., can solve the problems of complicated operation, easy to lift edges, etc., and achieve simple operation steps, not easy to lift up, and clean and beautiful shoe uppers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

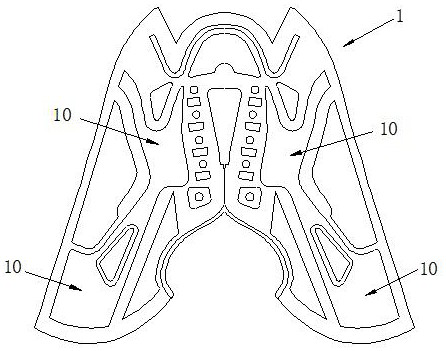

[0020] A kind of manufacturing technology of drop plastic vamp, this manufacturing technology includes the following steps of carrying out successively:

[0021] Step 1, place the shoe upper mold 1 on the workbench, drop the liquid drop plastic material into the groove 10 of the shoe upper mold 1, and then transfer the shoe upper mold 1 to an oven for drying. The temperature of the oven is 300°C. 1 The drying time in the oven is 4 minutes;

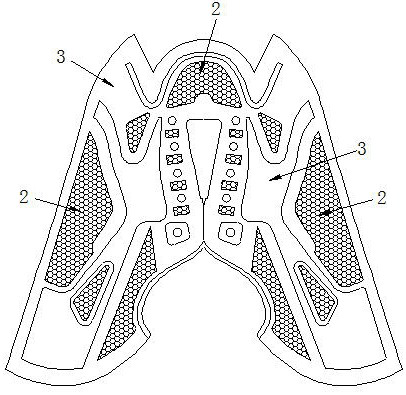

[0022] Step 2, take out the shoe upper mold 1 from the oven, and wait for the plastic drop material to be properly cooled and formed into a solid drop plastic sheet 3;

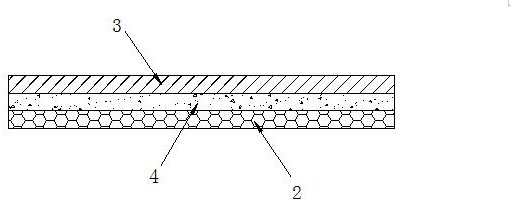

[0023] Step 3, place the shoe upper material sheet on the workbench, stack the hot melt adhesive film 4 on the shoe upper material sheet, and then stack the solid plastic drop sheet 3, when the shoe upper is made of cloth, you need to use the hot melt adhesive film , after being overlapped, they are welded together by heating equipment to form a drop-plastic upper; the ab...

Embodiment approach 2

[0027] A kind of manufacturing technology of drop plastic vamp, this manufacturing technology includes the following steps of carrying out successively:

[0028] Step 1, place the shoe upper mold 1 on the workbench, drop the liquid drop plastic material into the groove 10 of the shoe upper mold 1, and then transfer the shoe upper mold 1 to an oven for drying. The temperature of the oven is 150°C. 1 The drying time in the oven is 2 minutes;

[0029] Step 2, take out the shoe upper mold 1 from the oven, and wait for the plastic drop material to be properly cooled and formed into a solid drop plastic sheet 3;

[0030] Step 3, place the shoe upper material sheet on the workbench. When the shoe upper material sheet is made of leather, the shoe upper material sheet is directly stacked with a solid drop plastic sheet 3, and after overlapping, it is welded together by a heating device to form a drop plastic shoe upper; The above-mentioned heating equipment is a high-frequency machine...

Embodiment approach 3

[0034] A kind of manufacturing technology of drop plastic vamp, this manufacturing technology includes the following steps of carrying out successively:

[0035] Step 1, place the shoe upper mold 1 on the workbench, drop the liquid drop plastic material into the groove 10 of the shoe upper mold 1, and then transfer the shoe upper mold 1 to an oven for drying. The temperature of the oven is 250°C. 1 The drying time in the oven is 3 minutes;

[0036] Step 2, take out the shoe upper mold 1 from the oven, and wait for the plastic drop material to be properly cooled and formed into a solid drop plastic sheet 3;

[0037] Step 3, placing the shoe upper material sheet on the workbench, stacking the hot melt adhesive film 4 on the shoe upper material sheet, and then stacking the solid drop plastic sheet 3; after overlapping, it is welded by heating equipment to form a drop plastic shoe upper; The above-mentioned heating equipment is a high-frequency machine or a vamp hot-press forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com