False eyelash separating and feeding device

A technology of false eyelashes and eyelashes, applied in the field of false eyelash separation, can solve the problems of low false eyelash separation efficiency and high production cost, and achieve the effect of overcoming high production cost, high production efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

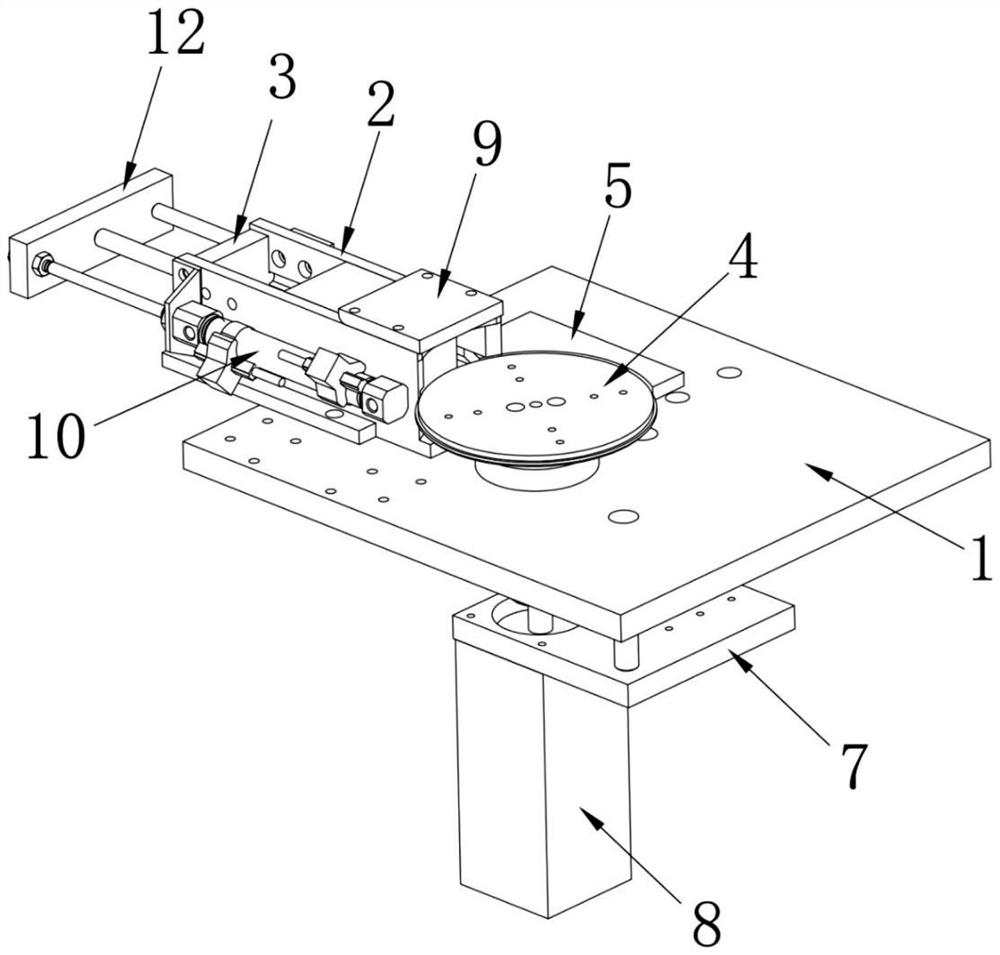

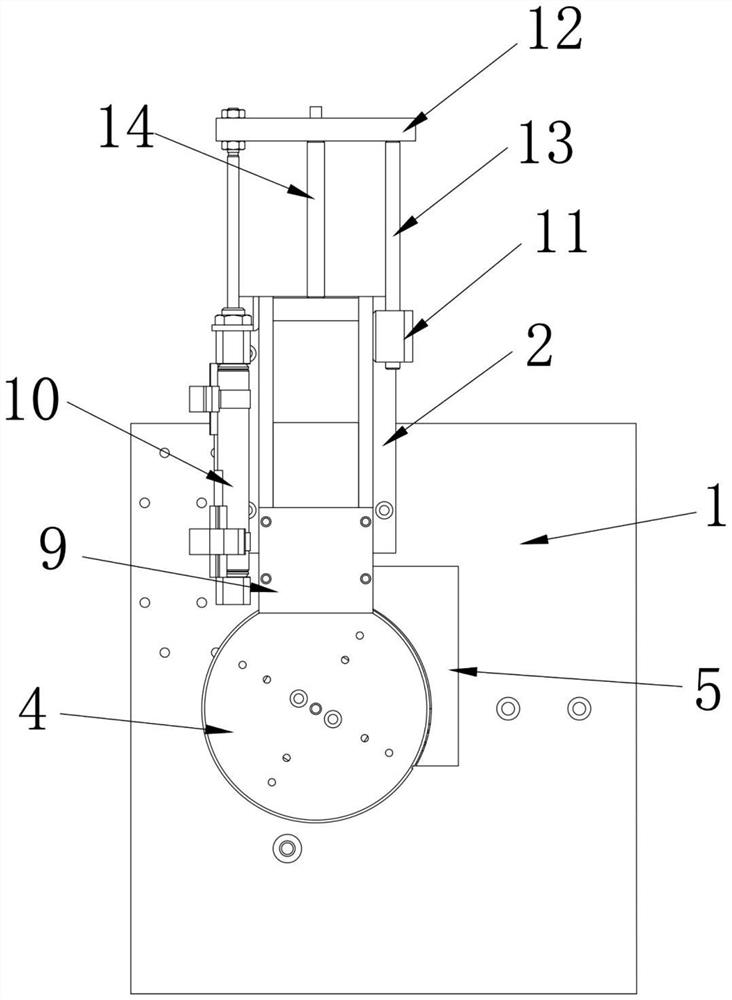

[0034] refer to Figure 1 to Figure 7 , this embodiment provides a false eyelash separation and feeding device, including a workbench 1, a material storage box 2 and a separation fixture 4, the workbench 1 is provided with a feeding station and a separation station, and the material storage box 2 is detachable Installed on the feeding station, the material storage box 2 is provided with a material storage tank 201, and the material storage tank 201 is used to accommodate eyelash raw materials. One end of the material storage tank 201 is provided with a material outlet 202 , and a push plate 3 is slidably installed in the material storage tank 201 . The separation jig 4 is located on the separation station and is installed close to the discharge port 202. The separation jig 4 is provided with a distribution trough 401 that is compatible with eyelash product specifications. For separation, the size of the distribution tank 401 can be determined according to the size of the raw ...

Embodiment 2

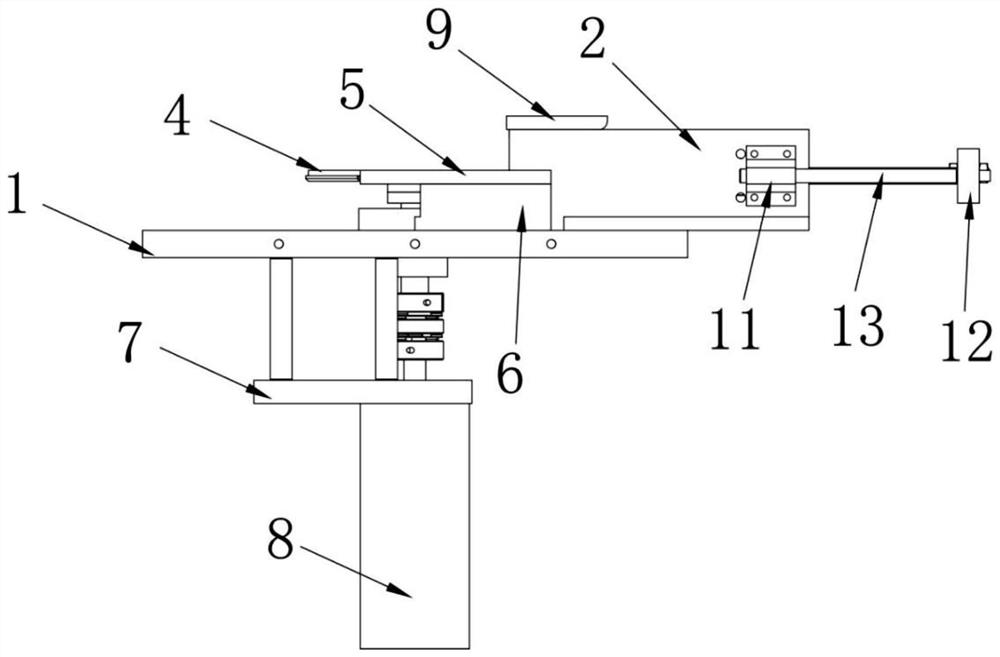

[0041] The difference between the device for separating and feeding false eyelashes provided in this embodiment and that in Embodiment 1 lies in that the shape and movement mode of the separating jig 4 are different.

[0042] refer to Figure 8 with Figure 9 In this embodiment, the separation jig 4 is plate-shaped, and at least one distribution groove 401 is arranged on its side wall along a straight line, and the separation jig 4 can reciprocate under the drive of the cylinder.

[0043] The device for separating and feeding false eyelashes provided by the present invention manually puts the raw materials of eyelashes into the storage box during operation, sorts the wool materials in the storage box, ensures that the raw materials of eyelashes are neatly arranged in the storage box, and packs them into the storage box. The upper cover; manually pass the storage box through the positioning pin and other limiting devices, quickly position the storage box to the loading station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com