High-flowability high-AN-content bulk ABS resin and preparation method thereof

An ABS resin, high-flow technology, applied in the ABS field, can solve the problems of long process, high amount of residual orders, large amount of waste, etc., and achieve the effect of white color and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

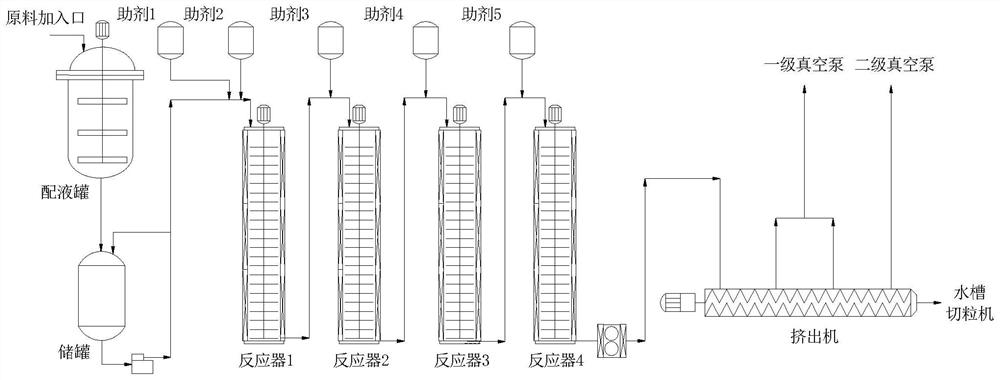

Method used

Image

Examples

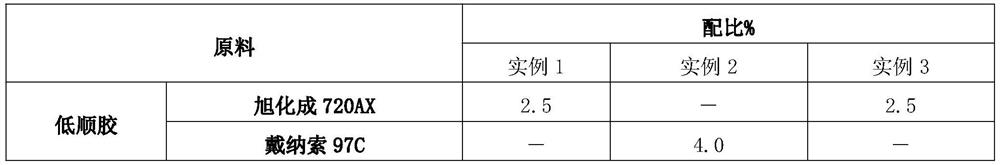

Embodiment 1

[0049] 1) The temperature control of each reaction zone is shown in Table 3

[0050] Table 3 Example 1 The control temperature of each zone of the reactor

[0051]

[0052] 2) The dosage of each additive

[0053] The amount of additive 1 is 42 g / hour; the amount of additive 2 is 60 g / hour; the amount of additive 3 is 192 g / hour; the amount of additive 4 is 243 g / hour; the amount of additive 5 is 52 g / hour.

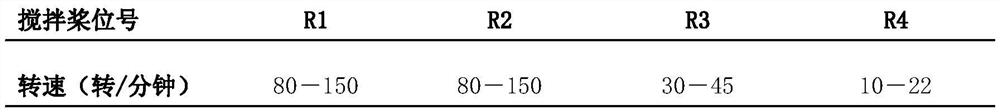

[0054] 3) Rotational speed of stirring paddles in each reactor

[0055]The stirring speed of R1 is 125 rpm; the stirring speed of R2 is 125 rpm; the stirring speed of R3 is 37 rpm; the stirring speed of R4 is 12 rpm.

Embodiment 2

[0057] 1) The temperature control of each reaction zone is shown in Table 4

[0058] Table 4 Example 2 The control temperature of each zone of the reactor

[0059]

[0060] 2) The dosage of each additive

[0061] The amount of additive 1 is 42 g / hour; the amount of additive 2 is 55 g / hour; the amount of additive 3 is 192 g / hour; the amount of additive 4 is 207 g / hour; the amount of additive 5 is 135 g / hour.

[0062] 3) Rotational speed of stirring paddles in each reactor

[0063] The stirring speed of R1 is 125 rpm; the stirring speed of R2 is 140 rpm; the stirring speed of R3 is 37 rpm; the stirring speed of R4 is 12 rpm.

Embodiment 3

[0065] 1) The temperature control of each reaction zone is shown in Table 5

[0066] Table 5 Example 3 The control temperature of each zone of the reactor

[0067]

[0068] 2) The dosage of each additive

[0069] The dosage of auxiliary agent 1 is 45 g / hour; the dosage of auxiliary agent 2 is 60 g / hour; the dosage of auxiliary agent 3 is 192 g / hour; the dosage of auxiliary agent 4 is 261 g / hour; the dosage of auxiliary agent 5 is 52 g / hour.

[0070] 3) Rotational speed of stirring paddles in each reactor

[0071] The stirring speed of R1 is 125 rpm; the stirring speed of R2 is 125 rpm; the stirring speed of R3 is 37 rpm; the stirring speed of R4 is 12 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com