Construction method for embedded part of transformer substation

A construction method and a technology of embedded parts, which are applied to building components, floors, buildings, etc., can solve the problems that the embedded parts cannot be guaranteed not to deviate, affect the position and height of the embedded parts, and the position deviation of the embedded parts, etc., to achieve Reduce rework and repair work, improve quality, and avoid the effect of displacement of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

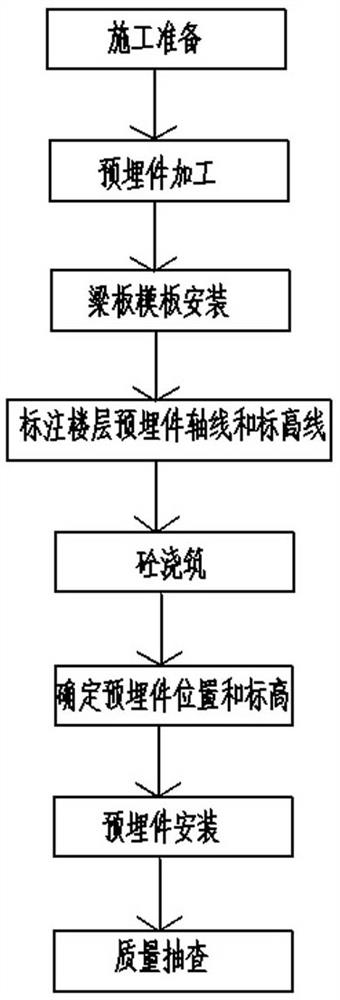

Method used

Image

Examples

Embodiment

[0024] Example: Embedded parts can be divided into stressed embedded parts and structural embedded parts, which are usually composed of two parts: one is embedded in concrete, and this kind of anchor bar generally adopts grade I or II steel bars; The anchor plate on the surface of the concrete is generally made of No. 3 steel plate or angle steel. The main function of the embedded parts is a more convenient process for later installation. It is very firm to directly weld the bracket or channel steel to the embedded parts during installation. Without embedded parts, the installation bracket or channel steel must be drilled in the floor, etc., and the expansion screws are installed. .

[0025] In the substation civil engineering, a large number of cable supports and channel steel between equipment need to be installed. The cable support and channel steel are all welded on the 10cm*10cm embedded parts that are pre-embedded in the concrete.

[0026] The following is a specific me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com