Transformer model measurement and analysis method

A transformer model, measurement and analysis technology, applied in the field of transformer analysis, can solve problems such as inaccurate data calculation, inaccurate transformer model load measurement, and inability to analyze the overall load state of vibration signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] refer to figure 1 , which is the first embodiment of the present invention, this embodiment provides a transformer model measurement and analysis method, including:

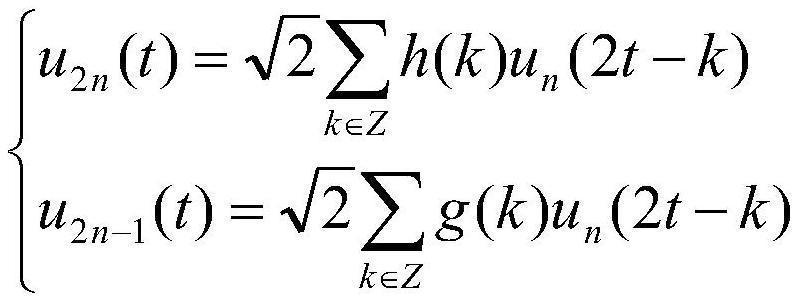

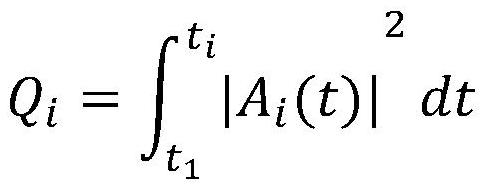

[0032] S1: Obtain the vibration signal and temperature of the transformer equipment through the acceleration sensing module and the temperature sensing module respectively, and perform feature extraction on the vibration signal.

[0033] In order to meet the characteristics and requirements of the vibration monitoring nodes of power distribution equipment and achieve the purpose of synchronously collecting acceleration vibration signals on three axes, this embodiment designs a three-axis high-bandwidth vibration monitoring node, and separately designs an acceleration sensing module, which can simultaneously collect three Axial vibration signals, and improved data acquisition accuracy and sampling frequency.

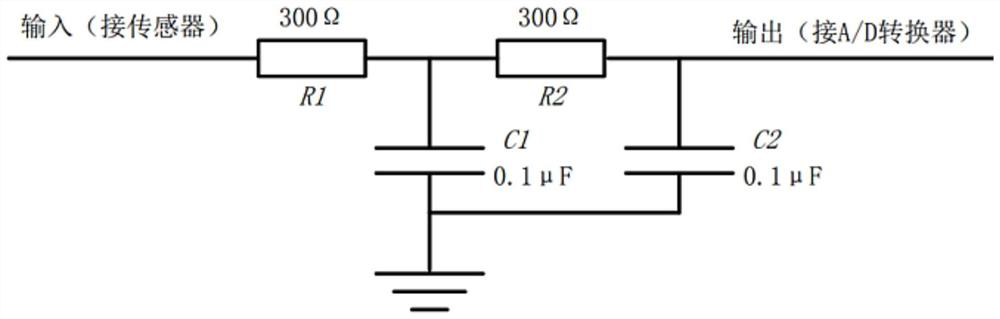

[0034] Specifically, the acceleration sensing module designed in this embodiment includes an acce...

Embodiment 2

[0066] In order to verify and explain the technical effect adopted in this method, this embodiment chooses the traditional technical scheme and adopts this method to conduct a comparative test, and compares the test results by means of scientific demonstration to verify the real effect of this method.

[0067] In order to verify that this method has higher measurement accuracy than the traditional technical solution, in this embodiment, the traditional technical solution and this method will be used to measure and compare the vibration signal, temperature and load value of the transformer in real time, and the results are shown in the table below.

[0068] vibration signal temperature load value traditional technical solutions 91.5% 91% 92% This method 100% 97% 97%

[0069] It can be seen from the above table that this method can measure vibration signals, temperature and load values more accurately than traditional technical solutions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com