Excess material management method and management system for sectional material

A management method and management system technology, which are applied in the field of residual material management methods and management systems for profiles, can solve the problems of inaccurate calculation of residual materials, low requirements for residual materials, waste and other problems, so as to solve inaccurate calculations and reduce materials. The effect of waste and promotion of secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

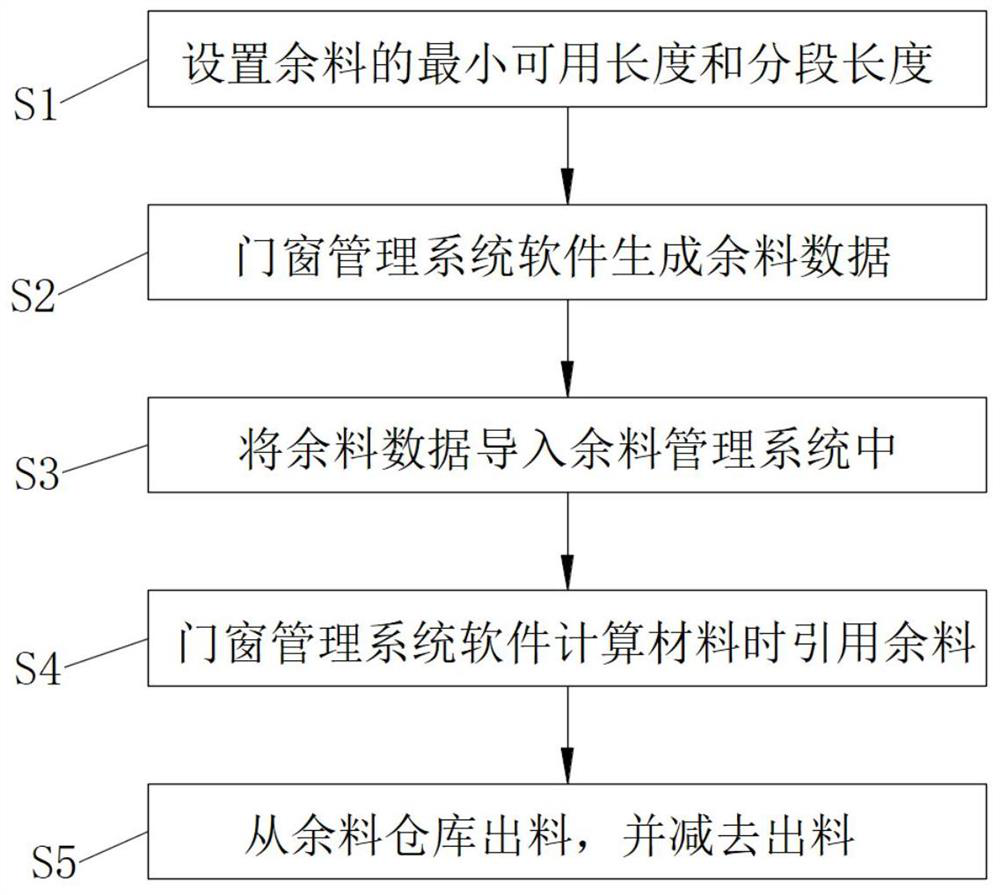

[0026] Such as Figure 1 to Figure 6 As shown, a profile management method for remaining materials, comprising the following steps:

[0027] S1, such as figure 2 As shown, set the minimum available length and segment length for the remaining material; the material after cutting the material is less than a certain value, there is no reuse value, and the minimum available value is different for different materials, so by setting different The minimum value of the residual material is used to remove the residual material that cannot be used; the length difference of different residual materials in the workshop may be small, it is not easy to distinguish when picking materials, and the amount of residual materials with different gradients cannot be clearly seen during management; therefore, by setting The section length of different residual materials manages the residual material according to the interval, which is convenient for the door and window factory to effectively class...

Embodiment 2

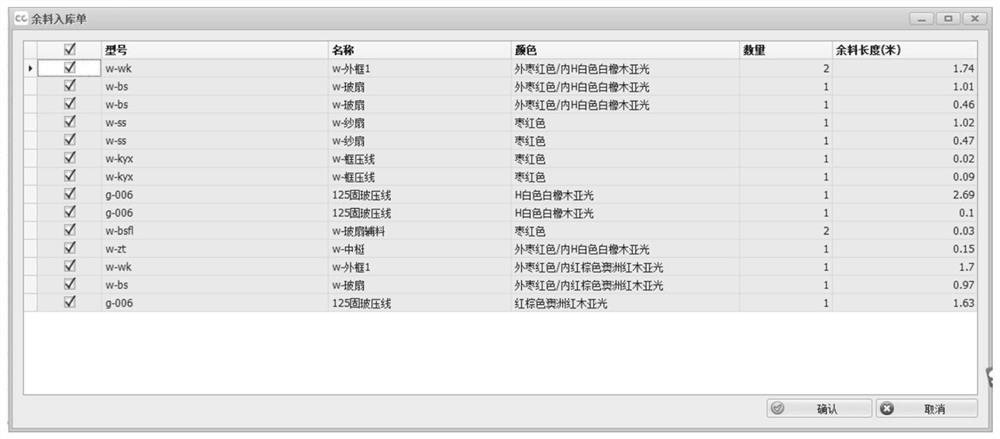

[0036] Such as figure 2 and Figure 4 As shown, a residual material management system for profiles includes: residual material setting module and residual material inventory module; residual material setting module includes: residual material minimum length setting unit and residual material stock segmentation length unit; residual material inventory module Including: type, name, color, length and quantity of remaining material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com