Polyethylene fiber special garment capable of reducing impact

A polyethylene fiber and special technology, which is applied in the field of special clothing, can solve the problems of workers falling to the ground, severe impact injuries of workers' bodies, and inability to form effective protection for the head and back.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

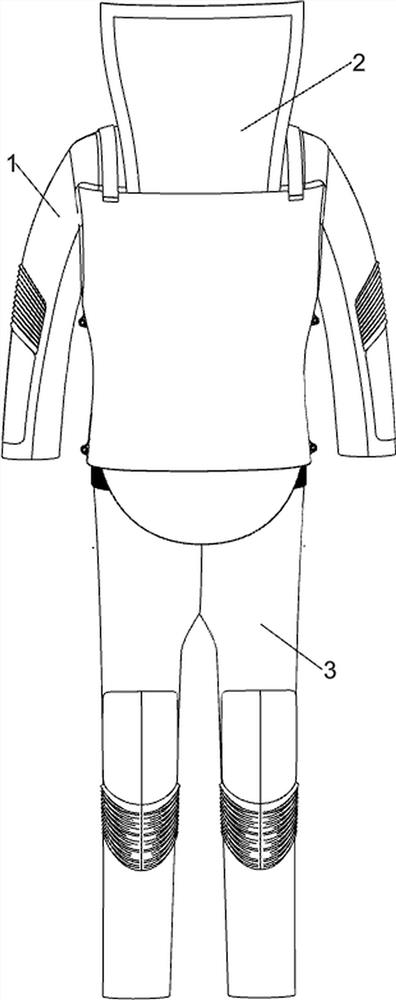

[0035] according to Figure 1-2 As shown, a special garment of impact-reducing polyethylene fiber includes a protective upper garment 1, a work protective component 2, a protective lower garment 3 and a back protective component 4; A protective lower garment 3 is provided; a back protective component 4 is sewn on the inner rear side of the protective upper garment 1 .

[0036]When the staff need to carry out boiler work, pressure vessel work and blasting work, they can wear special clothes made of impact-reducing polyethylene fibers. Before overhauling boiler pipe valves, workers can wear protective upper garment 1 and protective lower garment 3, and Put on the work protection component 2, and then form all-round protection for the head, upper body and lower body. In case of an accident, the protective upper garment 1, the work protective component 2 and the protective lower garment 3 can avoid direct impact damage from steam flow and broken pipe fragments , during the blasti...

Embodiment 2

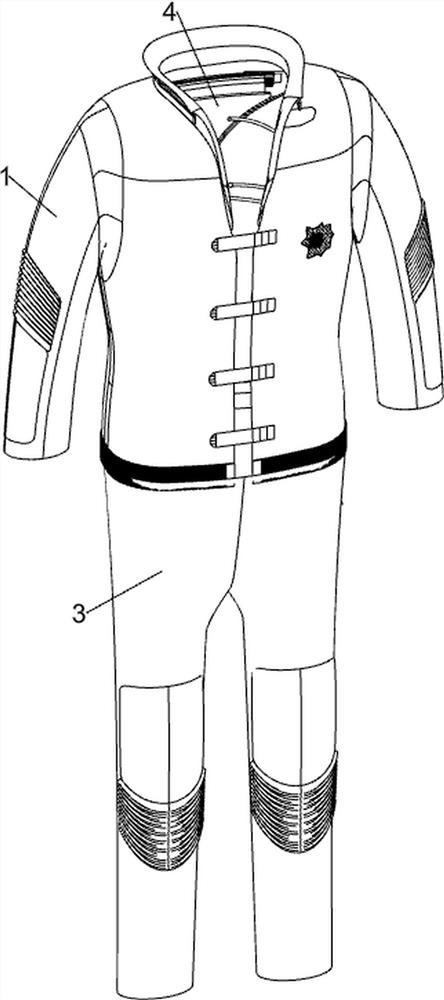

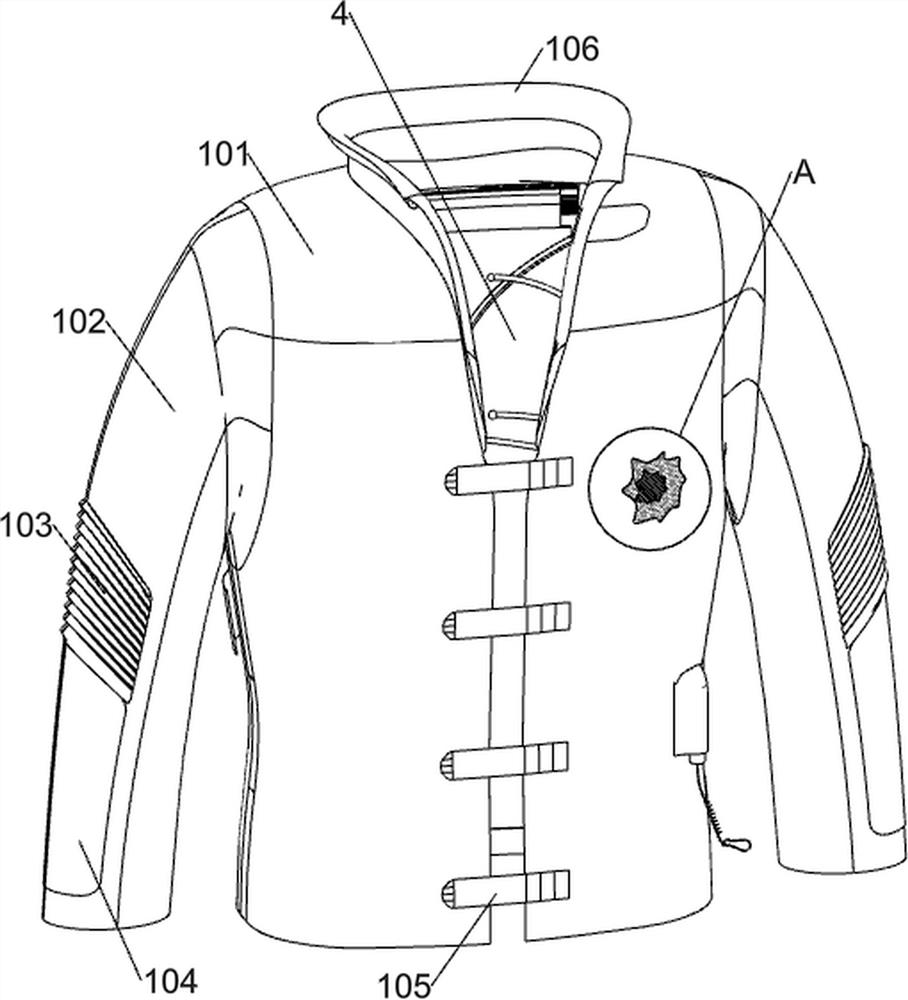

[0038] On the basis of Example 1, according to Figure 3-7 As shown, the protective jacket 1 includes a polyethylene fiber jacket 101, protective jacket sleeves 102, sleeve protection components, Velcro 105, a protective collar 106 around the airbag, an airbag bursting assembly and an airbag trigger assembly; the polyethylene fiber jacket 101 left A protective sleeve 102 is sewed on the side upper part and the right upper part respectively; the rear side of the polyethylene fiber jacket 101 is provided with an airbag bursting assembly; the front lower right side of the polyethylene fiber jacket 101 is provided with an airbag trigger assembly; Connect the work protection component 2; the rear side of the polyethylene fiber top 101 is provided with a back protection component 4; the airbag trigger component is connected to the back protection component 4; two protective sleeves 102 are each sewn with a sleeve protection component; the polyethylene fiber top 101 A plurality of ma...

Embodiment 3

[0051] On the basis of Example 2, according to Figure 8-9 As shown, the work protection assembly 2 includes a first connection strap 201, a front body armor 202, a transparent head shield 203, a gas flow rate detector 204, a neck strap 205 and a second connection strap 206; Belt 201, front body armor 202, head transparent protective cover 203, gas velocity detector 204, neck belt 205 and the second connection belt 206; Two shoulders of polyethylene fiber tops 101 are respectively bonded with a first A connecting belt 201; two first connecting belts 201 are sewn with front body armor 202 at the bottom of the front side; the top of the front body armor 202 is fixedly connected with a head transparent protective cover 203; There are two gas flow rate detectors 204; the lower left side of the front body armor 202 and the lower right side of the rear part are respectively sewn with two second connecting straps 206; the four second connecting straps 206 are all bonded to the polyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com