Chaenomeles sinensis distillation extraction method applied to Chaenomeles sinensis wine

A technology of distilling and extracting fragrant wood, which is applied in the field of fragrant papaya distillation and extraction, can solve the problems of unfavorable production of fragrant papaya wine, low alcohol content of fragrant papaya wine, affecting the production and quality of wine, so as to avoid complicated aroma components, strong wine taste, and improve Yield and Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

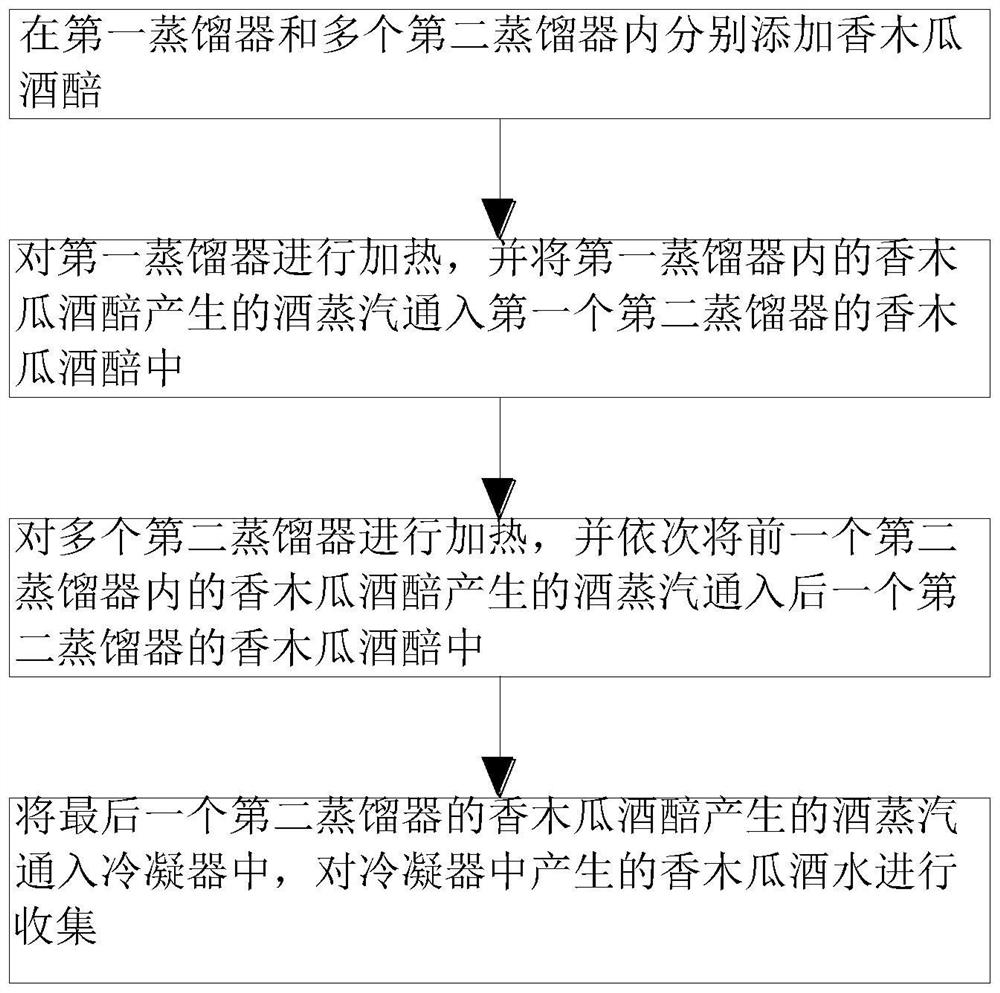

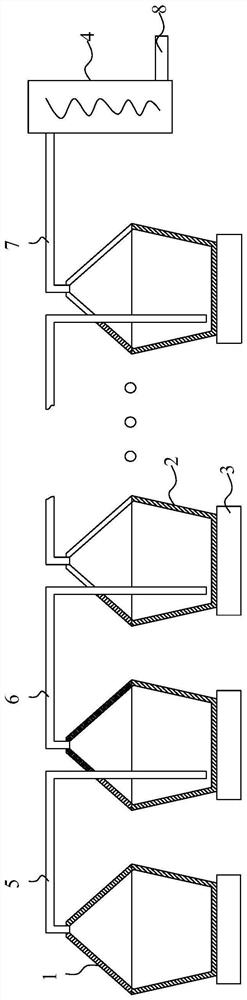

[0028] A method for distilling and extracting fragrant papaya applied to fragrant papaya wine, comprising the steps of:

[0029] 1) Add fragrant papaya wine unstrained spirits respectively in the first distiller 1 and multiple second distillers 2;

[0030] 2) heating the first still 1, and passing the wine steam produced by the fragrant papaya wine grains in the first still 1 into the fragrant papaya wine grains of the first second still 2;

[0031] 3) multiple second stills 2 are heated, and the wine steam produced by the fragrant papaya wine grains in the previous second still 2 is passed into the fragrant papaya wine grains in the next second still 2 in sequence;

[0032] 4) The wine vapor produced by the fragrant papaya wine grains of the last second distiller 2 is passed into the condenser 4, and the fragrant papaya wine produced in the condenser 4 is collected.

[0033] Further, the heating process of the heater 3 includes the following steps:

[0034] Step 1, the init...

Embodiment 2

[0043] A method for distilling and extracting fragrant papaya applied to fragrant papaya wine, comprising the steps of:

[0044] 1) Add fragrant papaya wine unstrained spirits respectively in the first distiller 1 and multiple second distillers 2;

[0045] 2) heating the first still 1, and passing the wine steam produced by the fragrant papaya wine grains in the first still 1 into the fragrant papaya wine grains of the first second still 2;

[0046] 3) multiple second stills 2 are heated, and the wine steam produced by the fragrant papaya wine grains in the previous second still 2 is passed into the fragrant papaya wine grains in the next second still 2 in sequence;

[0047] 4) The wine vapor produced by the fragrant papaya wine grains of the last second distiller 2 is passed into the condenser 4, and the fragrant papaya wine produced in the condenser 4 is collected.

[0048] Further, the heating process of the heater 3 includes the following steps:

[0049] Step 1, the init...

Embodiment 3

[0058] A method for distilling and extracting fragrant papaya applied to fragrant papaya wine, comprising the steps of:

[0059] 1) Add fragrant papaya wine unstrained spirits respectively in the first distiller 1 and multiple second distillers 2;

[0060] 2) heating the first still 1, and passing the wine steam produced by the fragrant papaya wine grains in the first still 1 into the fragrant papaya wine grains of the first second still 2;

[0061] 3) multiple second stills 2 are heated, and the wine steam produced by the fragrant papaya wine grains in the previous second still 2 is passed into the fragrant papaya wine grains in the next second still 2 in sequence;

[0062] 4) The wine vapor produced by the fragrant papaya wine grains of the last second distiller 2 is passed into the condenser 4, and the fragrant papaya wine produced in the condenser 4 is collected.

[0063] Further, the heating process of the heater 3 includes the following steps:

[0064] Step 1, the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com