Associated reference telecentric measurement quick calibration method under super-field-of-view scale

A calibration method and field of view technology, which is applied in image data processing, complex mathematical operations, instruments, etc., can solve the problems of increased cost, limited accurate extraction of elements, and inability to image at the same time, achieving the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

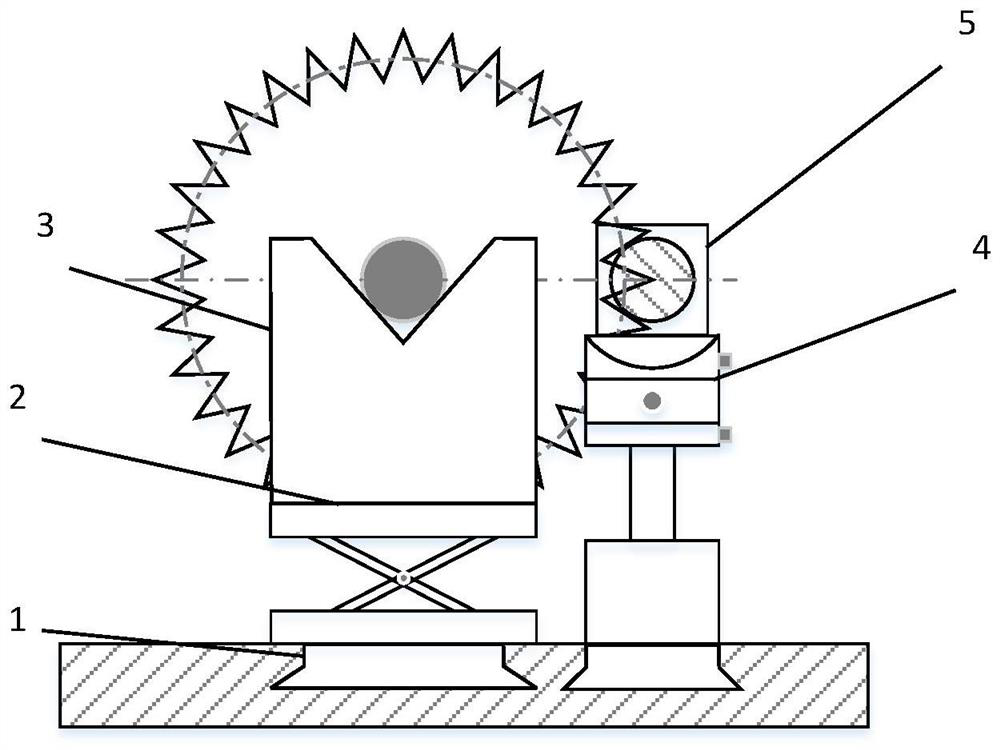

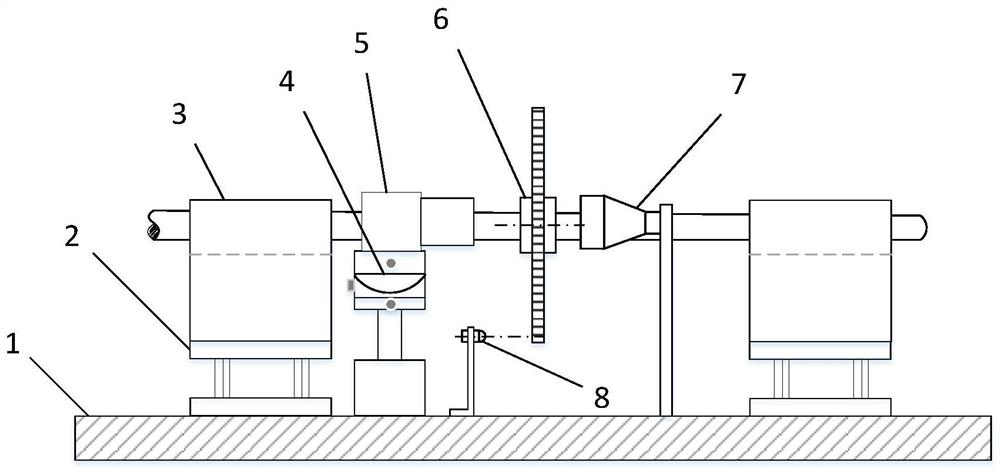

[0067] The embodiment of the present invention is as Figure 2 to Figure 5 shown.

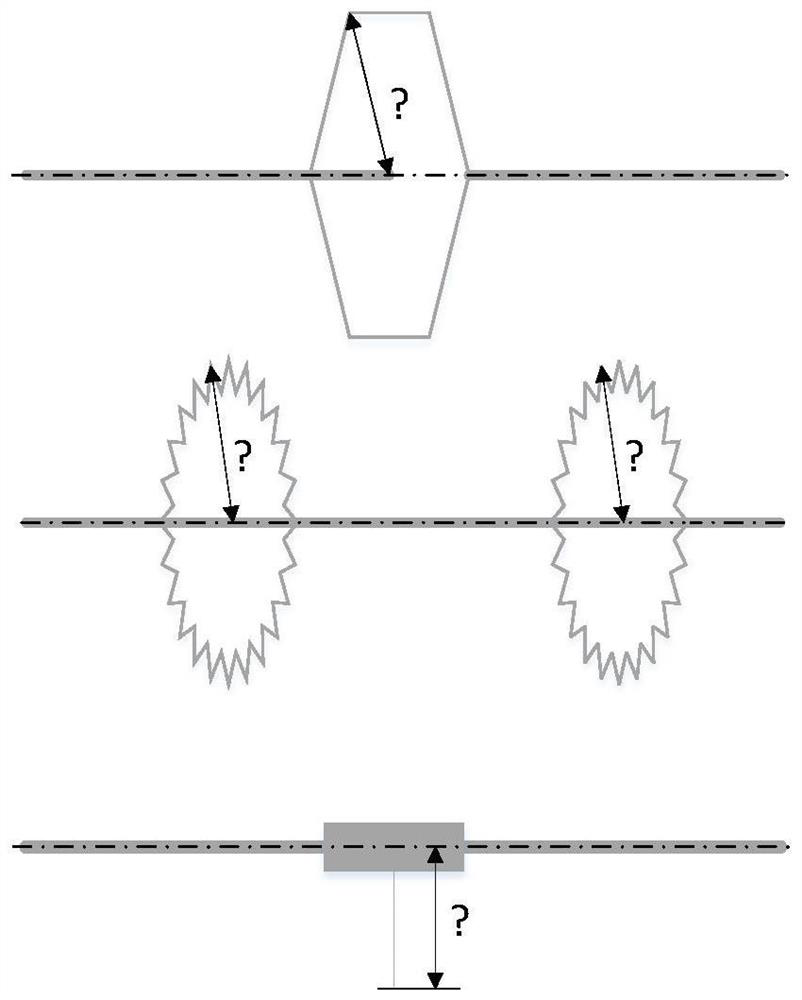

[0068] like figure 2 , image 3 As shown, the telecentric vision system includes: a workbench 1, a precision pose adjustment mechanism 4, a measuring camera 5, a workpiece to be measured 6, a background light source 7, a triggerable photoelectric induction mechanism 8, a transmission target 9 and a three-dimensional associated target 10 The composed telecentric vision system needs to take into account both fast and high-precision measurement requirements. The vision measurement system is designed as a narrow field of view high-precision telecentric vision measurement system. Its monitoring field of view only covers the protruding tip elements of the cross-section of the workpiece to be measured. , to ensure high-precision measurement of geometric elements in the local measurement area of the workpiece to be measured.

[0069] According to the technical parameters of each component, the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com