Plasma cleaning protection device and method for rigid-flex board

A technology of flexible and rigid boards and plasma, which is applied in the processing of insulating substrates/layers, electrical components, and printed circuit manufacturing. Direct contact, solve the effect of bubbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

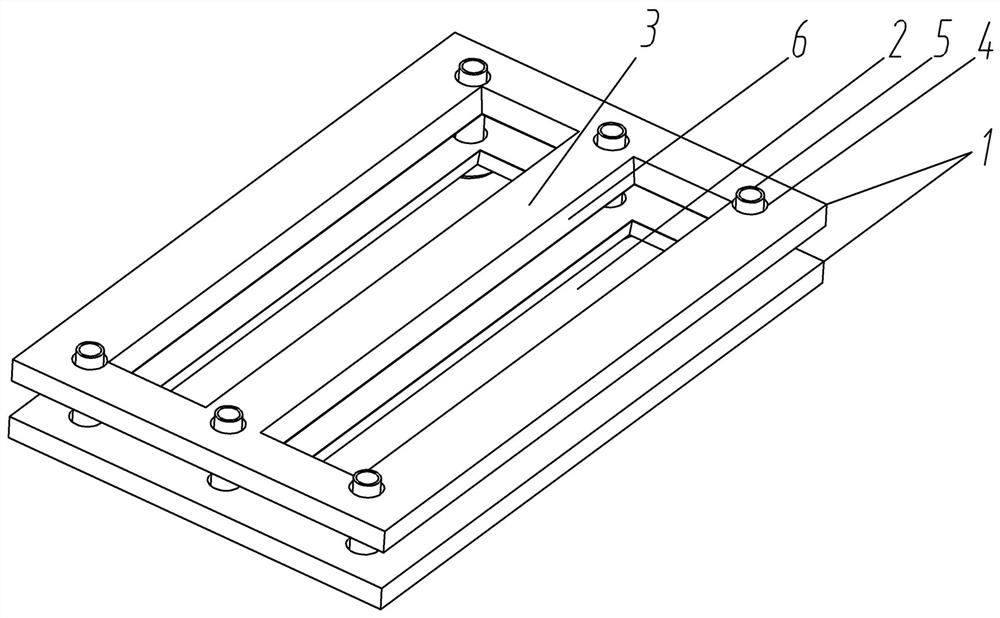

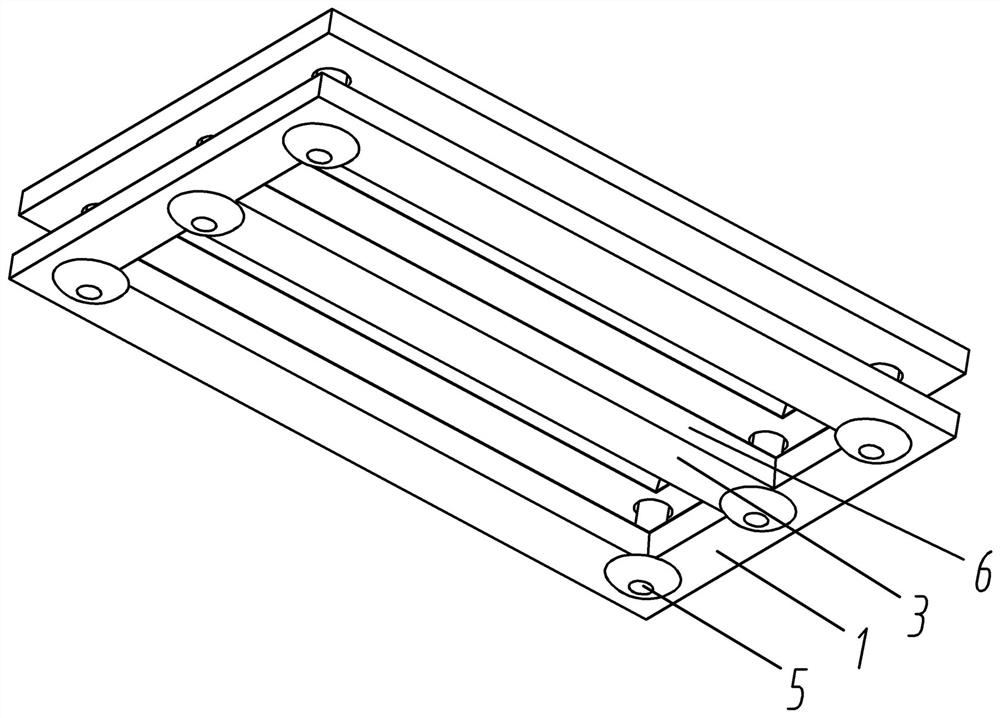

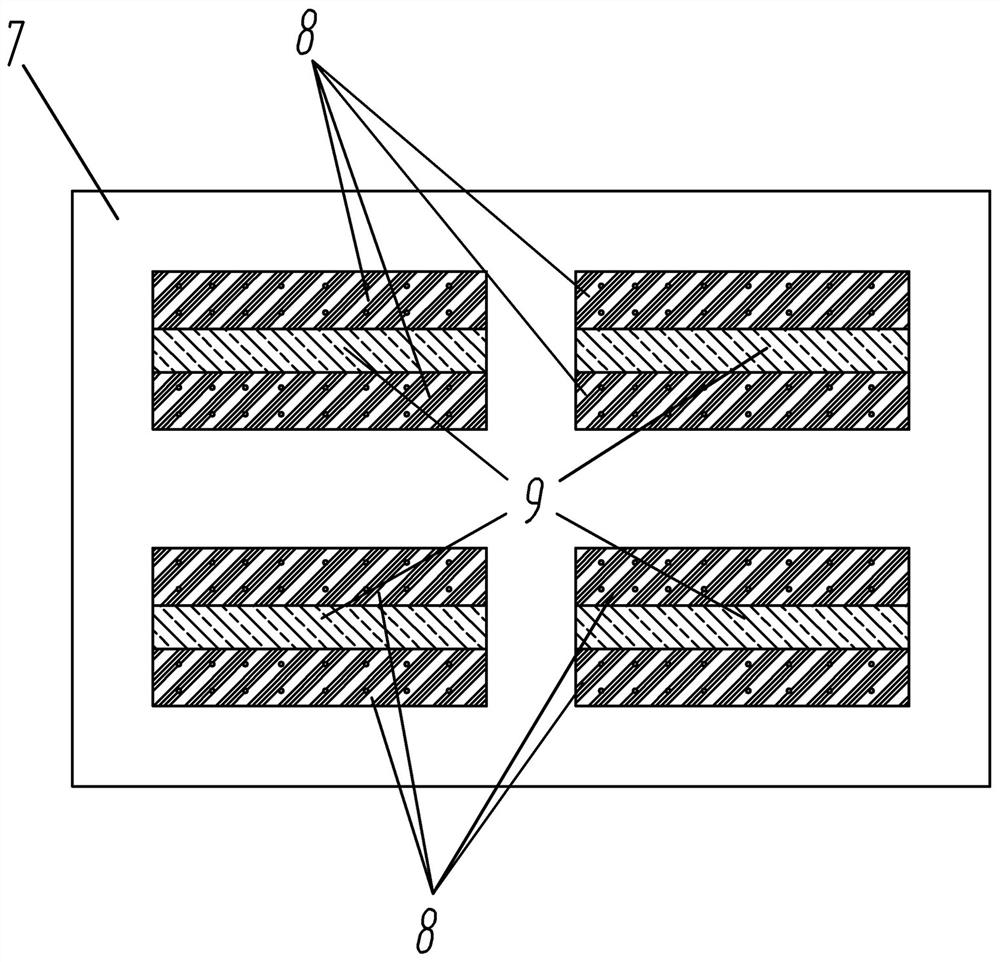

[0032] like figure 1 and figure 2 As shown, in this embodiment, the present invention includes two substrates 1, the substrate 1 is provided with a through-hole area 2, and in the through-hole area 2 is provided with a baffle suitable for the soft board. plate 3, both ends of the baffle plate 3 are connected to the hole wall of the through-hole area 2, and several positioning holes 4 are arranged on the substrate 1 and around the through-hole area 2, one of which is Each of the positioning holes 4 on the substrate 1 is provided with a hollow rivet 5, and the positioning hole 4 on the other substrate 1 passes through the hollow rivet 5, so that the two substrates 1 are overlapped. When in use, the rigid-flex board 7 is located between the two substrates 1, the hard plate 8 of the rigid-flex board 7 is exposed to the outside through the through-hole area 2, and the soft board 9 of the rigid-flex board is covered by the two The baffle plate 3 on the substrate 1 is completely c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap