Hand grinder coupler structure

A technology for connecting structures and grinding wheels, which is applied to the device for fixing grinding wheels, parts of grinding machine tools, grinding machines, etc. It can solve the problems of operator inconvenience and unloading, and achieve the effect of improving efficiency and reducing the unit price of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings, but the characteristic structures and functions thereof are shown as an example of configuration, and therefore are not limited to the embodiments described in this specification.

[0022] First, the technology disclosed in Korean Patent Laid-Open Publication No. 10-0973157 will be described in detail as a preferred example of application of the present invention, and the problems caused by it will be deduced, and then the structure and effects of the present invention will be described later.

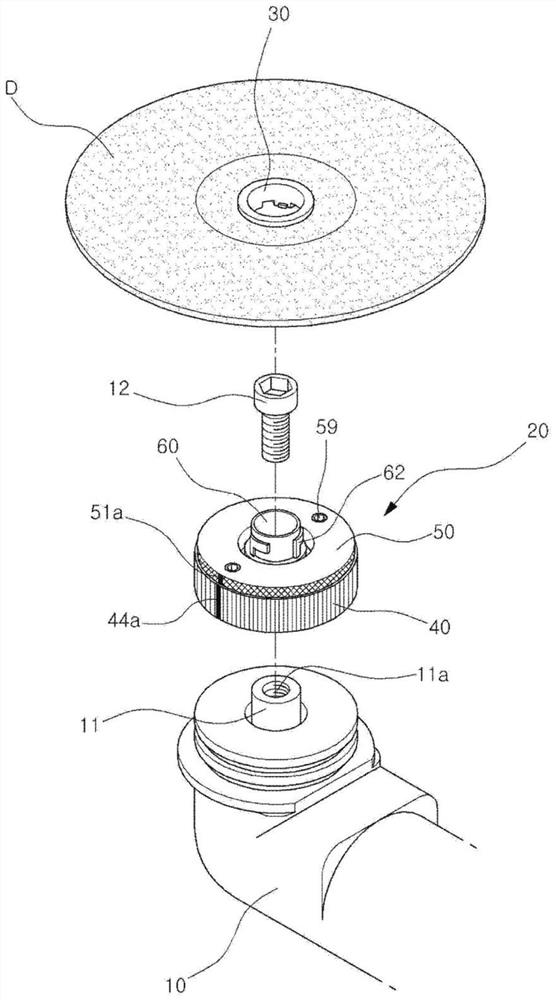

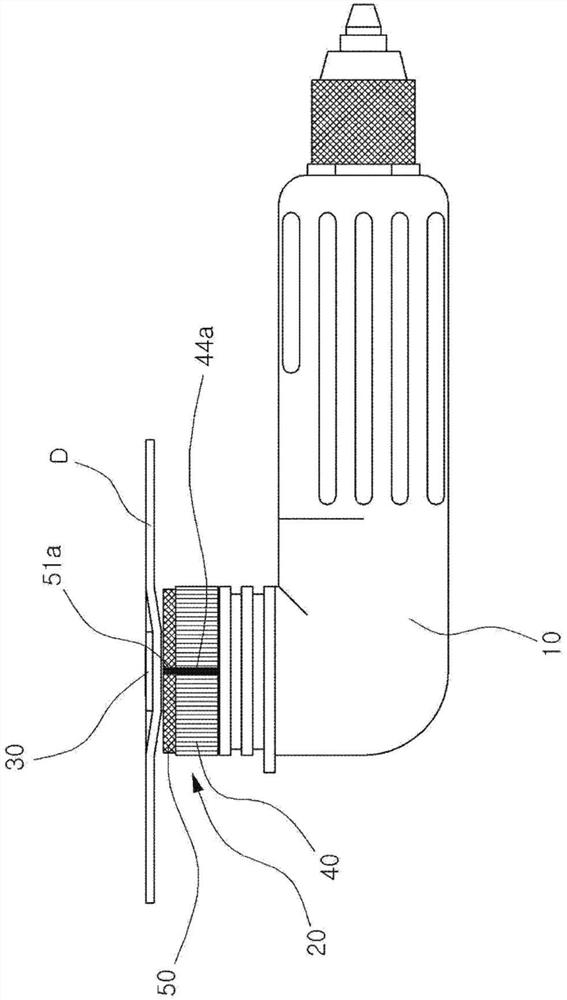

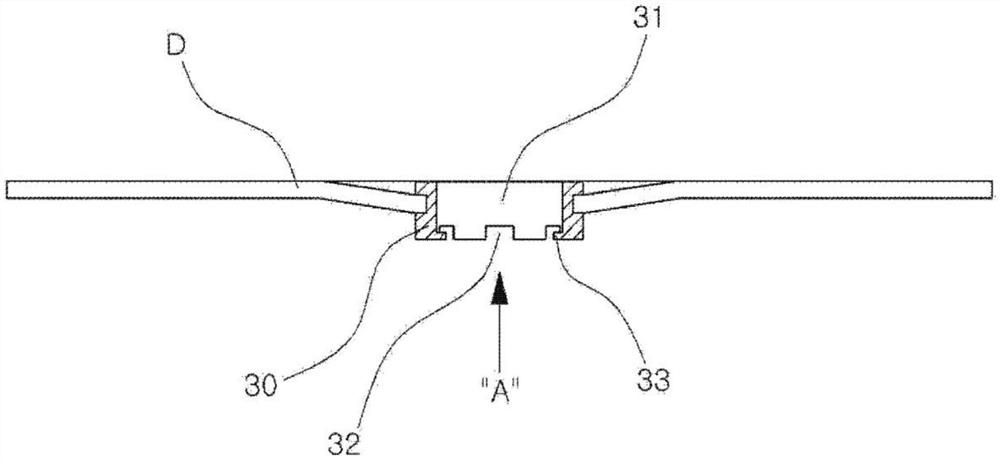

[0023] like Figure 1 to Figure 11 As shown, the manual grinding wheel is composed of a power coupling unit 20 including a normal grinding wheel main body 10 and a disc holder 30 in which a disc D is integrally mounted.

[0024] A rotating shaft 11 having a threaded hole 11a is provided at one front end of the grinding wheel body 10 to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com