Desulfuration and deoxidization agent prepared by means of metal smelting waste and preparation method of desulfuration and deoxidization agent

A technology of metal smelting and deoxidizer, applied in the direction of improving process efficiency, can solve problems such as failure to use resources and regional restrictions, and achieve the effect of preventing waste of land resources, reducing production costs, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

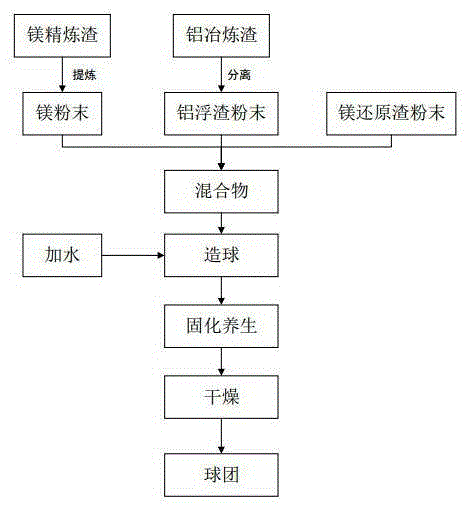

Method used

Image

Examples

Embodiment 1

[0032] The waste magnesium refining slag produced in the magnesium smelting process is pulverized and mixed with water or hydrochloric acid solution to separate metal magnesium and magnesium chloride. The separated metal powder is made into powder. Mix 0.3kg of magnesium powder, 0.3kg of aluminum scum powder and 10kg of magnesium reduction slag C2S powder to make a desulfurization and deoxidation agent.

[0033] Add the mixture to 1000kg of iron ore and measure its desulfurization degree. The test results show that the sulfur content in the steelmaking raw materials is 0.275ppm, and the desulfurization rate is 85%.

Embodiment 2

[0035] The waste magnesium refining slag produced in the magnesium smelting process is pulverized and mixed with water or hydrochloric acid solution to separate metal magnesium and magnesium chloride. The separated metal powder is made into powder. Mix 1kg of magnesium powder, 5kg of aluminum scum powder and 10kg of magnesium reduction slag C2S powder to make a desulfurization and deoxidation agent.

[0036] Add the mixture to 1000kg of iron ore and measure its desulfurization degree. The test results show that the sulfur content in the steelmaking raw materials is 0.272ppm, and the desulfurization rate is 89%.

Embodiment 3

[0038] The waste magnesium refining slag produced in the magnesium smelting process is pulverized and mixed with water or hydrochloric acid solution to separate metal magnesium and magnesium chloride. The separated metal powder is made into powder. Mix 2kg of magnesium powder, 3kg of aluminum scum powder and 10kg of magnesium reduction slag C2S powder to make a desulfurization and deoxidation agent.

[0039] Add the mixture to 1000kg of iron ore and measure its desulfurization degree. The test results show that the sulfur content in the steelmaking raw materials is 0.267ppm, and the desulfurization rate is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com