Casting device and casting method for large gear steel cast ingot

A large-scale gear and steel casting technology, applied in ingot workshops, casting molds, cores, etc., can solve the problems of difficulty, lack of tight microstructure integration, and large heat treatment, so as to improve efficiency and ensure the effect of repeated use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Unless otherwise specified, the examples are all in accordance with conventional experimental conditions. In addition, for those skilled in the art, on the premise of not departing from the spirit and scope of the present invention, various modifications or improvements to the material components and dosage in these embodiments all belong to the protection scope of the present invention.

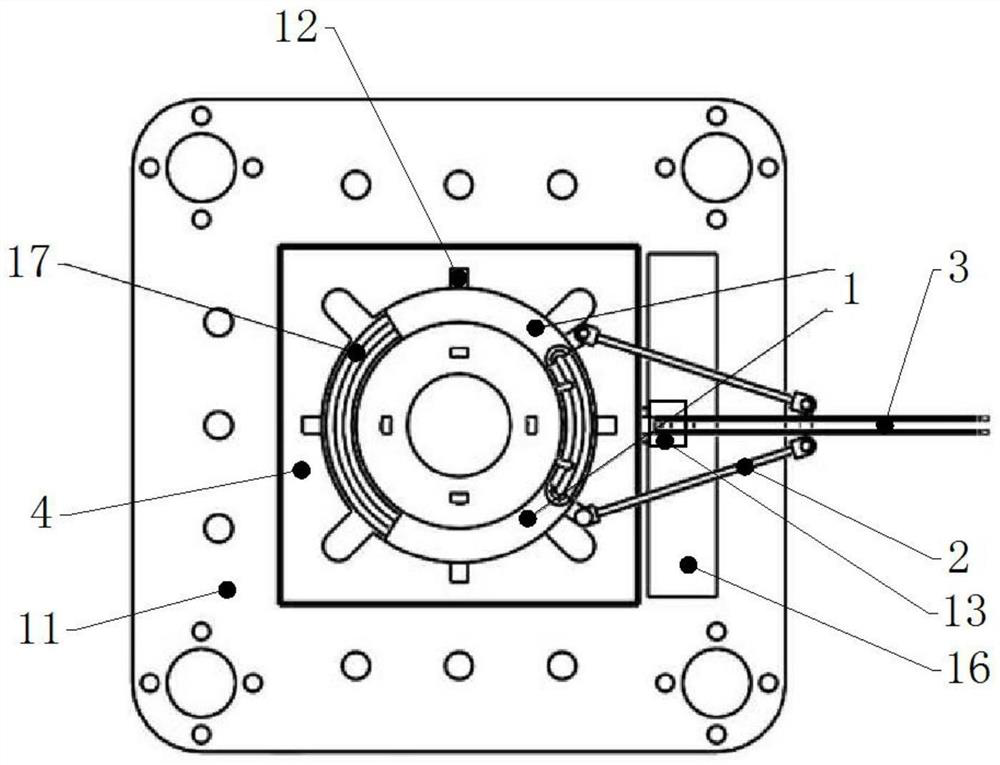

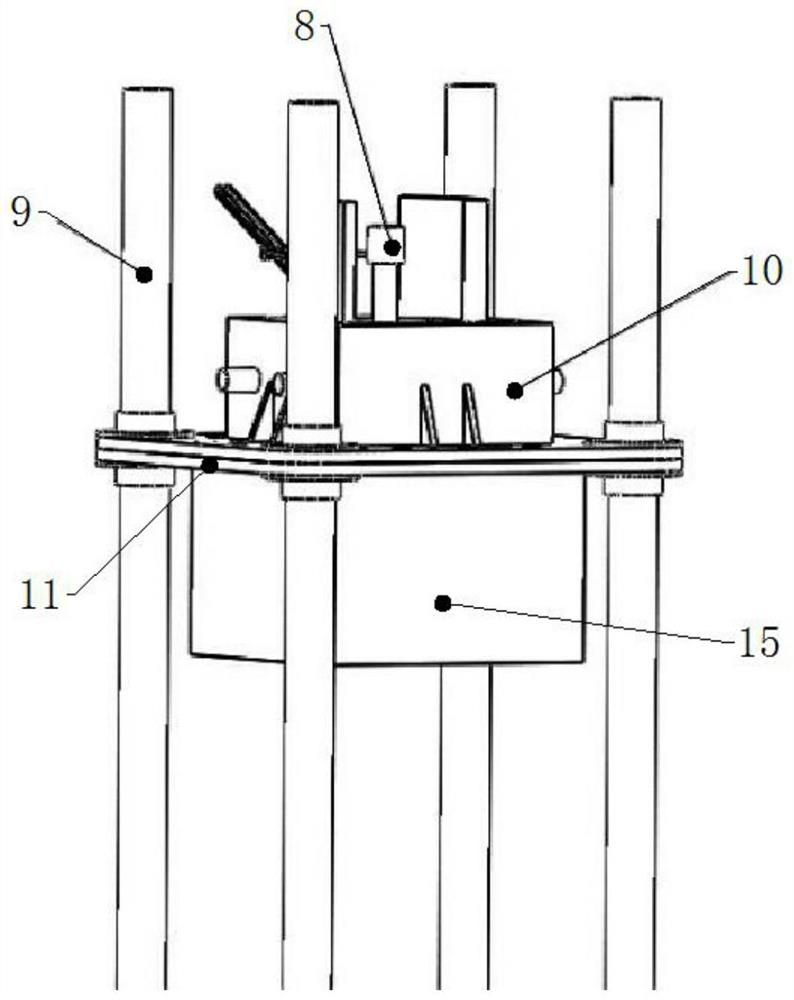

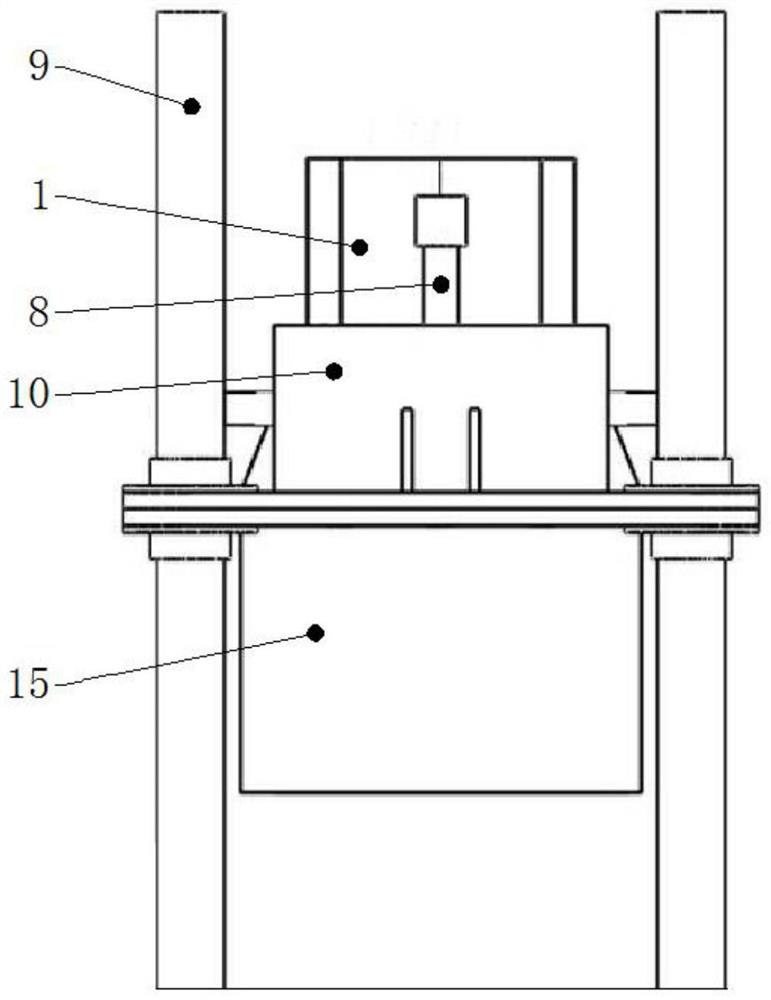

[0039] Such as Figure 1 to Figure 6 A casting device for a large gear steel ingot is shown, which includes a crystallizer 7, a guide post 9 and a working platform 11, wherein:

[0040] The four corners of the working platform 11 are respectively provided with guide pillars 9 along the vertical direction, and the working platform 11 reciprocates along the guide pillars 9, and a sealing plate 4 is arranged in the middle of the working platform 11, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap