Pass-type lifting and tilting transfer trolley for molten iron transfer

A transfer car and molten iron technology, applied in the direction of lifting devices, lifting frames, casting molten material containers, etc., can solve the problems of rotation time and other problems, achieve the effect of saving layout space, saving transfer time, and improving the transfer rate of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

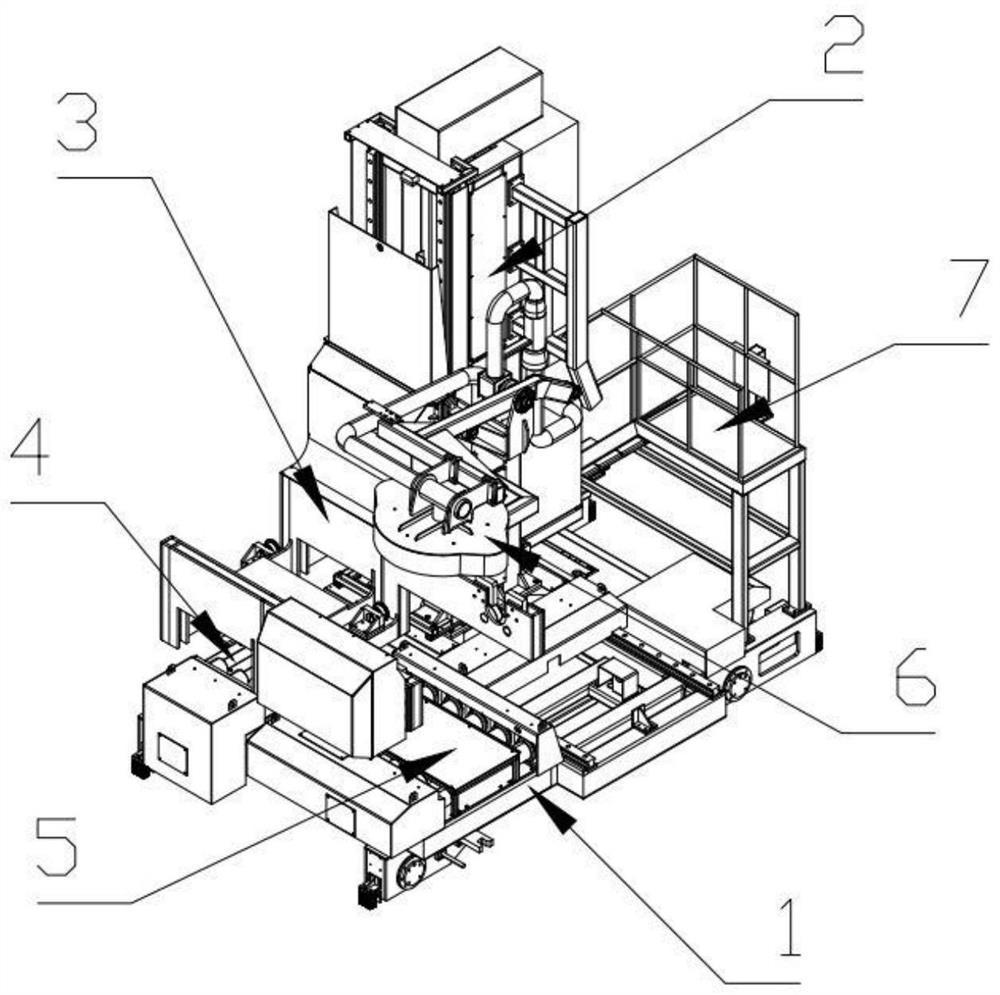

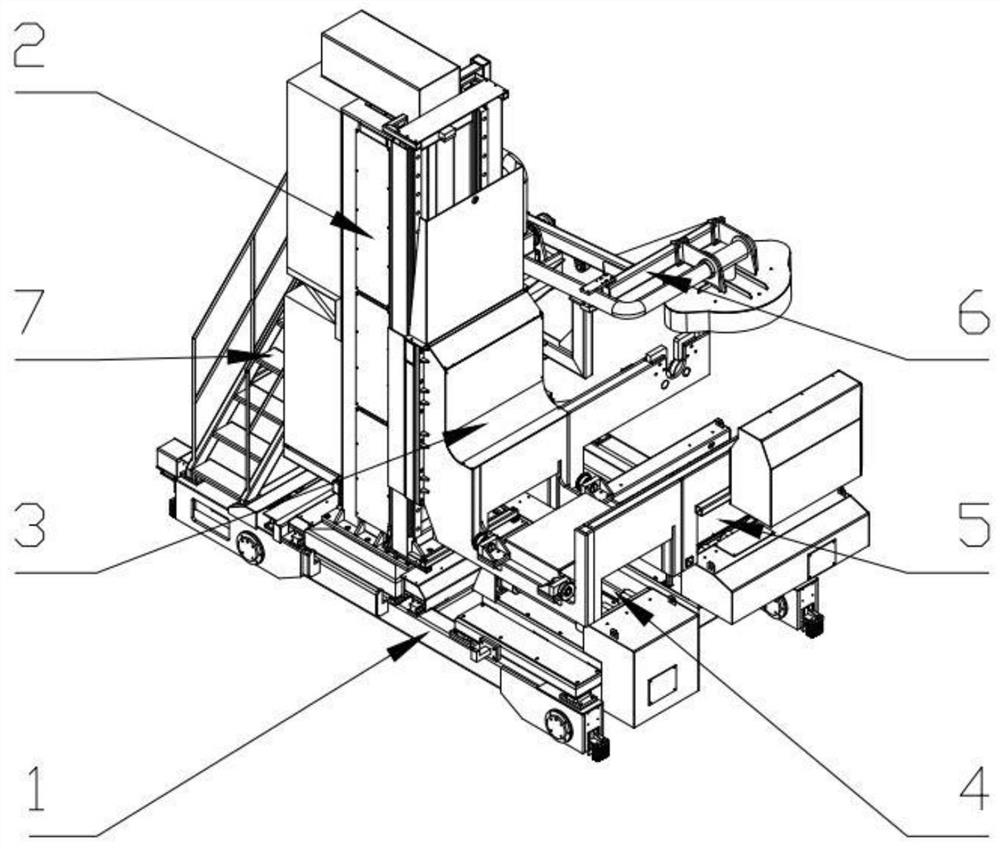

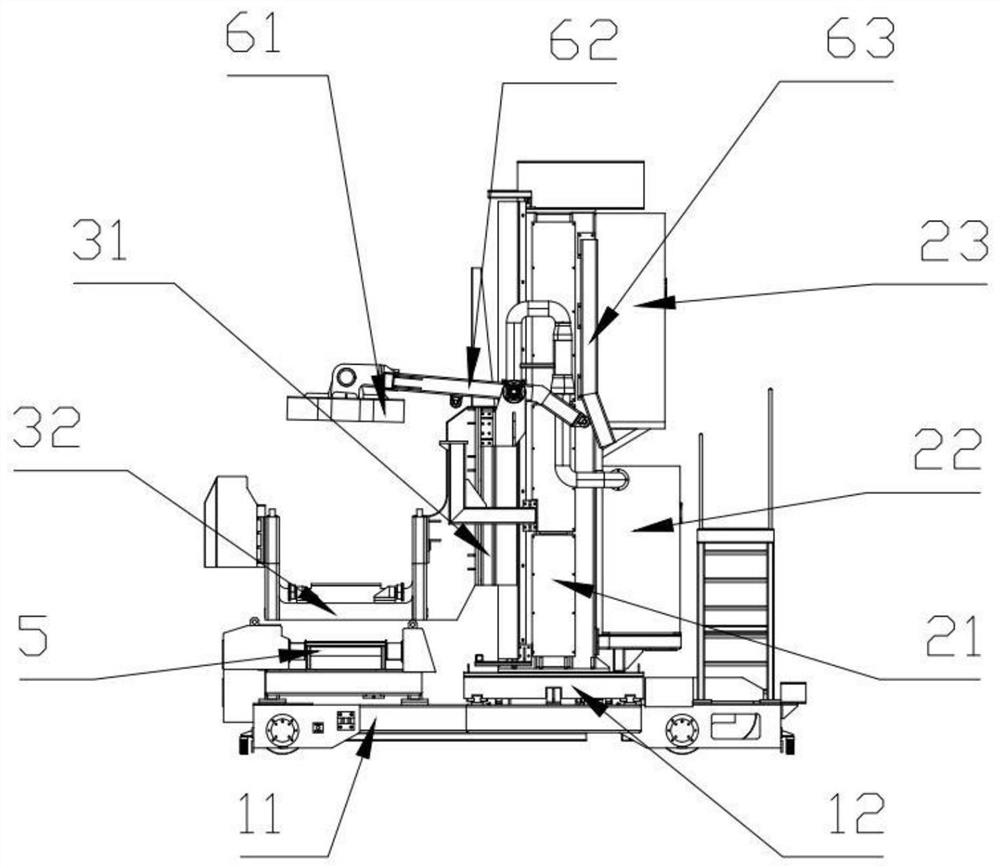

[0036] This embodiment provides a pass-through lifting and tilting transfer vehicle for molten iron transfer, see figure 1 , figure 2 , including a translation part 1, a column 2, a lifting part 3 and a roller table device, the translation part 1 is located at the bottom, and a column 2 is vertically provided on its upper part, and a lifting part 3 is slidingly provided on one side of the column 2. The roller table device is located on the upper part of the translation part 1 and below the lifting part 3 .

[0037] In this example, see Figure 3-Figure 6, the translation part 1 includes a car body 11 and a lateral movement module 12, the car body 11 is arranged horizontally, and wheels are arranged below it, and the wheels are connected with a translation drive machine, and the translation drive machine drives the wheels to rotate, thereby making the The car body 11 is driven by the wheels to reciprocate along the track. The traversing module 12 is located above the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com