Side head placing device convenient for replacing side milling cutter head

The technology of a side milling cutter and a boss is applied in the field of side head placement devices, which can solve the problems of operator scratches, reduced safety, and easy accidental touch, etc., to achieve high safety, improve protection effect, and protect unsafe hidden dangers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

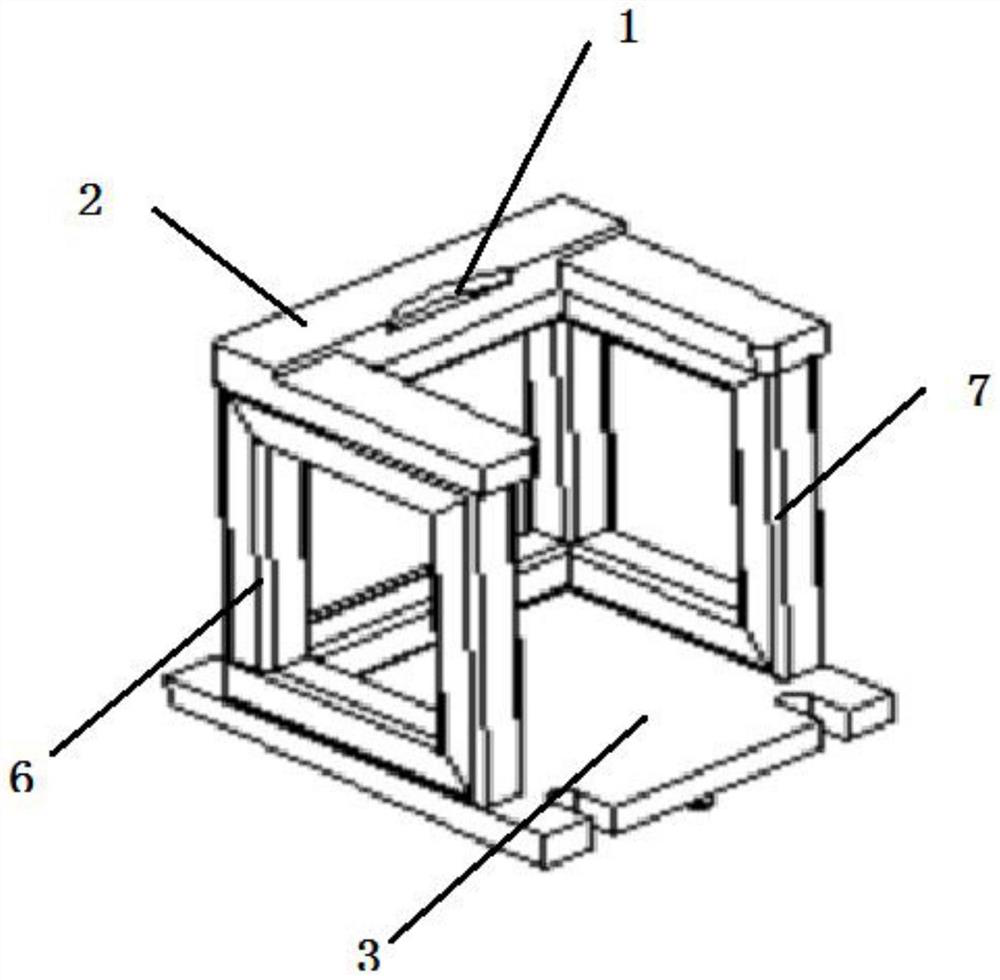

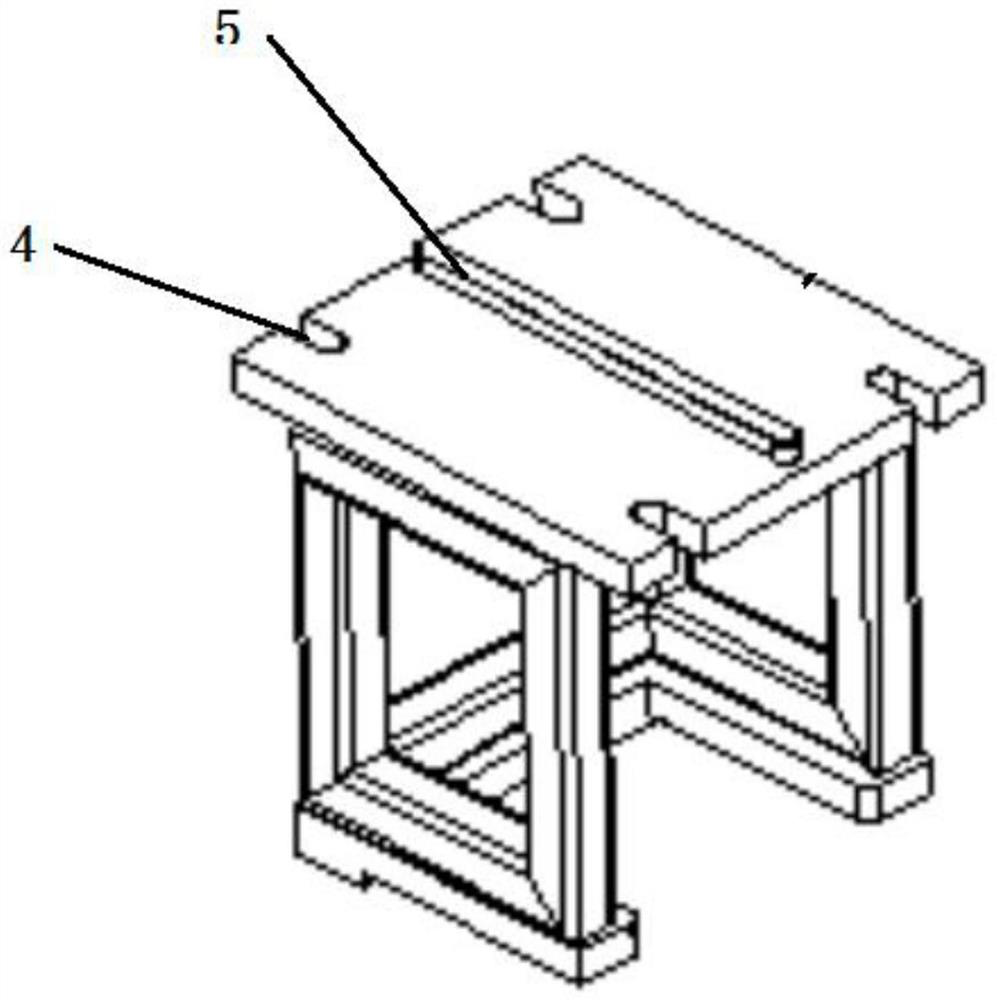

[0011] A side head placement device for easy replacement of side milling cutter heads, which is characterized in that it includes a boss 1, a front frame 2, a bottom plate 3, a left frame 6, and a right frame 7. The top of the boss 1 is installed with a front frame 2 through bolts, and the boss The left end of the top of platform 1 is equipped with a left frame 6 through bolts, and the right end of the top of the boss 1 is equipped with a right frame 7 through bolts. The front frame 2, left frame 6, and right frame 7 form a three-sided structure; the top of the front frame 2 is provided with a boss 1. The boss 1 is an arc-shaped structure, the bottom of the bottom plate 3 is provided with limiting grooves 5, and the front and rear ends of the bottom plate 3 are respectively provided with limiting grooves 5.

Embodiment 2

[0013] Before the present invention is used, when assembling the front frame 2, the left frame 6, the right frame 7, and the bottom plate 3, it is necessary to ensure that the welding bead at the joint is complete and smooth, and there is no air hole and slag inclusion, so as to avoid the occurrence of tooling on the side milling cutter head due to shape defects Secondary damage, the front and rear ends of the bottom plate 3 are designed with card slots 4 and the middle of the bottom plate 3 is designed with the limit groove 5 for positioning to ensure that it is fixed with the bottom plate 3 without shaking. The boss 1 on the top of the front frame 2 has a radian design to fit the side milling cutter The shape of the head is surrounded by a three-sided frame, which can more effectively protect the hidden dangers caused by the side milling cutter head during processing. Frame 2, left frame 6, and right frame 7 limit the position of the hand to prevent the operator from touching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com