A production process of high-precision shape and position tolerances and exquisite construction of prefabricated wall panels

A technology of shape and position tolerance and production process, which is applied in manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of prefabricated wall panels prone to lines, and the film is not flat enough, so as to achieve a smooth and flat surface and improve the surface. Flatness, the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

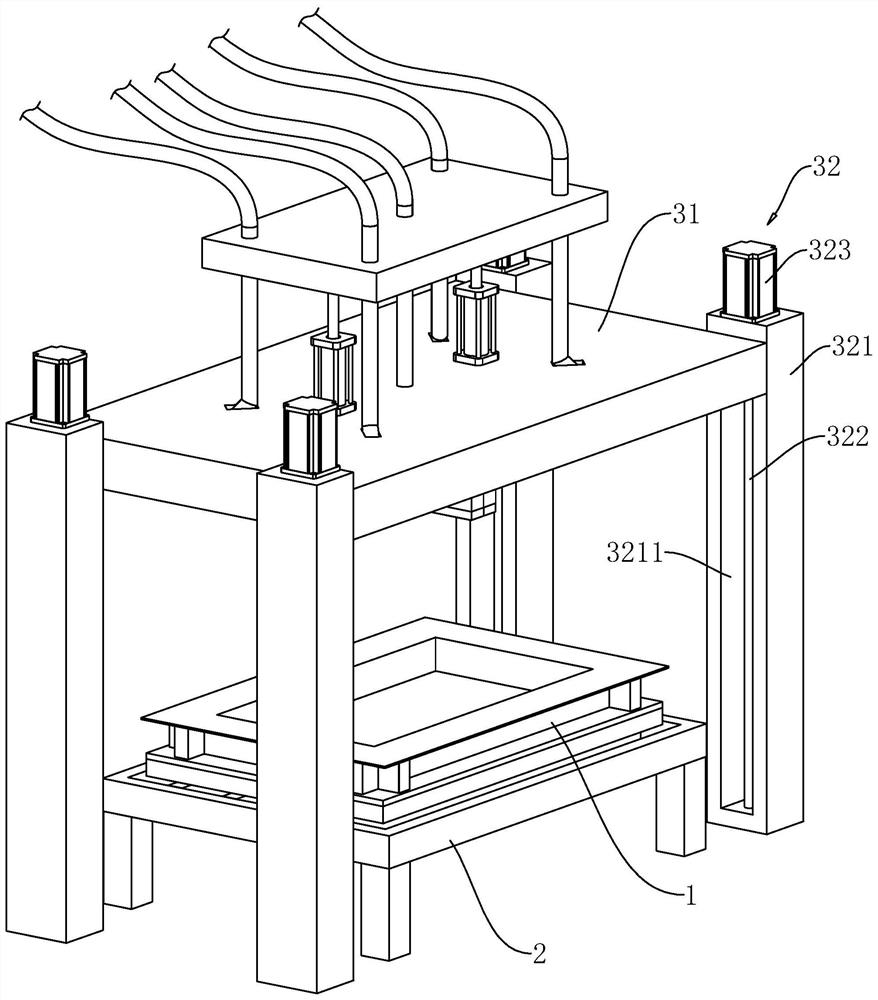

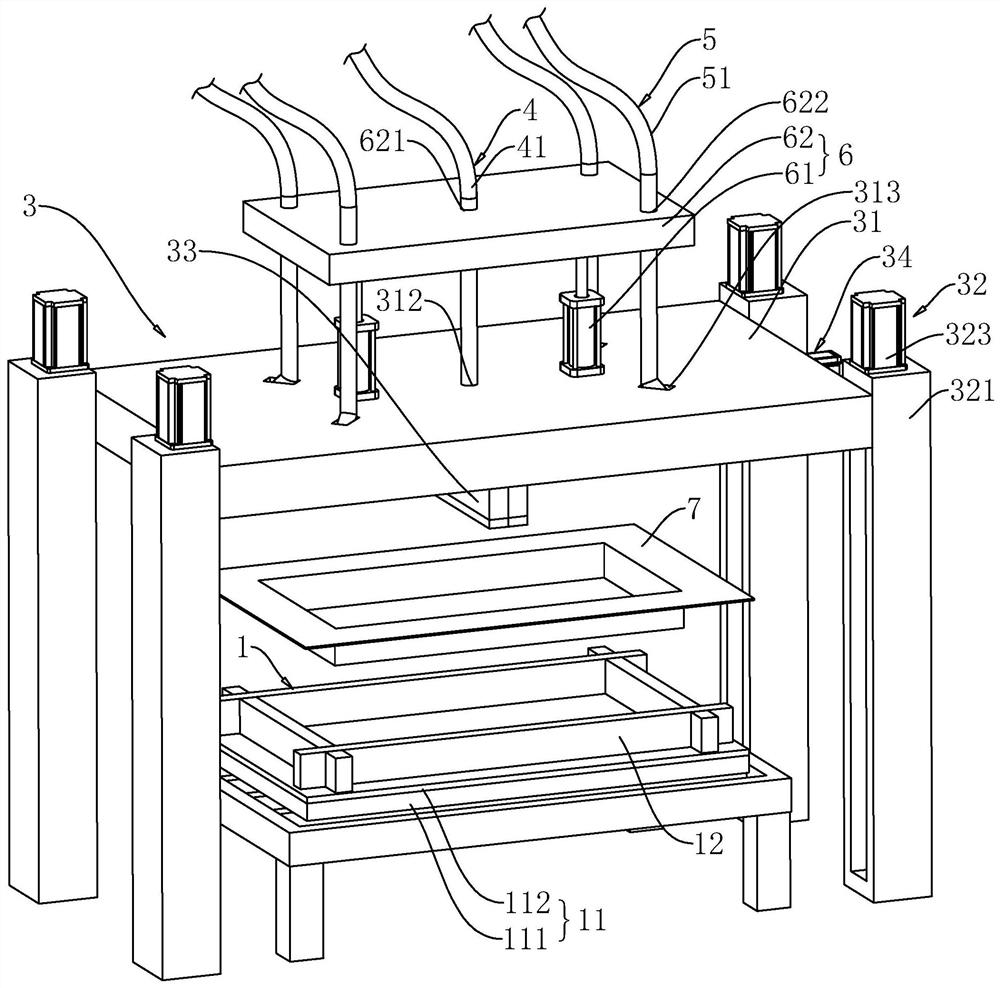

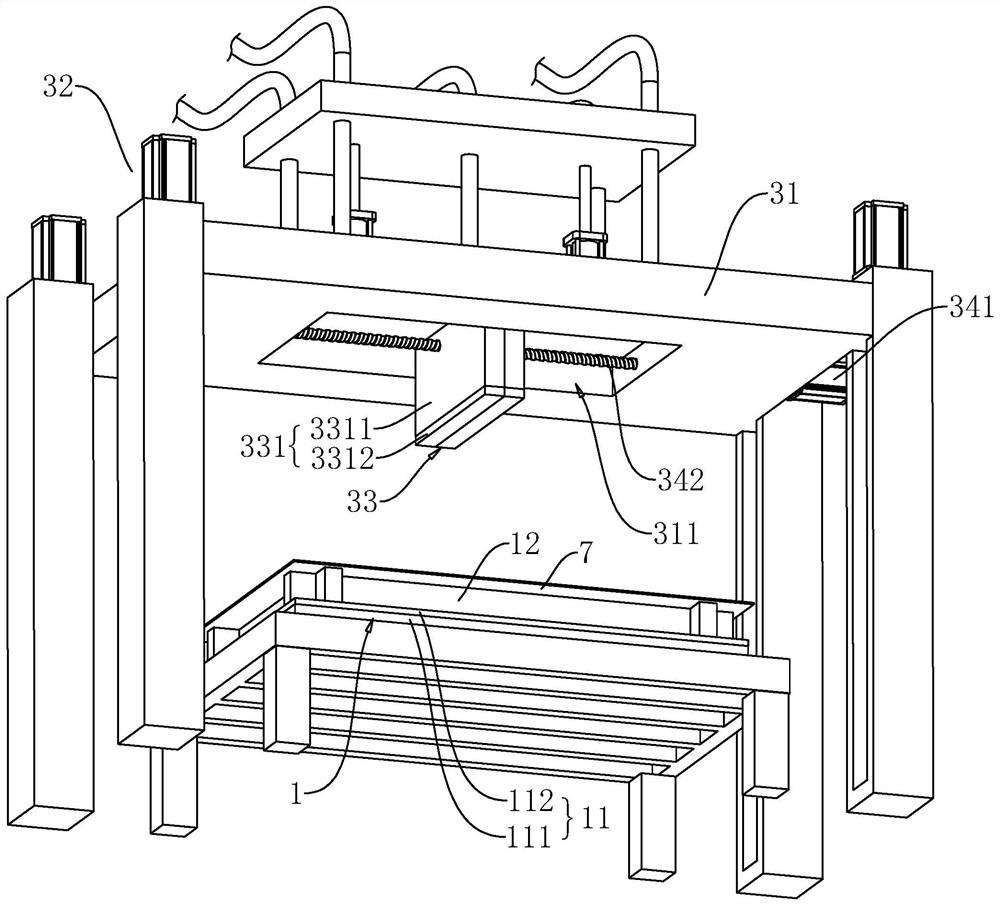

[0044] The following is combined with the attached Figure 1-4 Further elaboration of this application.

[0045] Embodiments of the present application disclose a high-precision geometric tolerance exquisite construction of prefabricated wall panel production process. Reference Figure 1 , the production process of the high-precision geometric tolerance of the present embodiment of the exquisite construction of the prefabricated wall panel comprises a forming mold 1 and a support frame 2 for the forming mold 1 placed.

[0046] Reference Figure 2 , the molding mold 1 is a box body, the molding comprises a bottom template 11 and four side templates 12, the ends of the four side templates 12 are connected in turn into a closed ring. The bottom plate 11 includes a support plate 111 and a glass plate 112, the glass plate 112 is glued to one side of the support plate 111, the ring formed by the four side templates 12 is fixed to the side of the glass plate 112 away from the support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com