Component fatigue degree monitoring method for special machinery

A technology of fatigue level and special machinery, applied in computer parts, neural learning methods, elevators, etc., can solve the problems of little effect and large manpower investment, and achieve the effect of high accuracy, improved accuracy, and rich fault types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

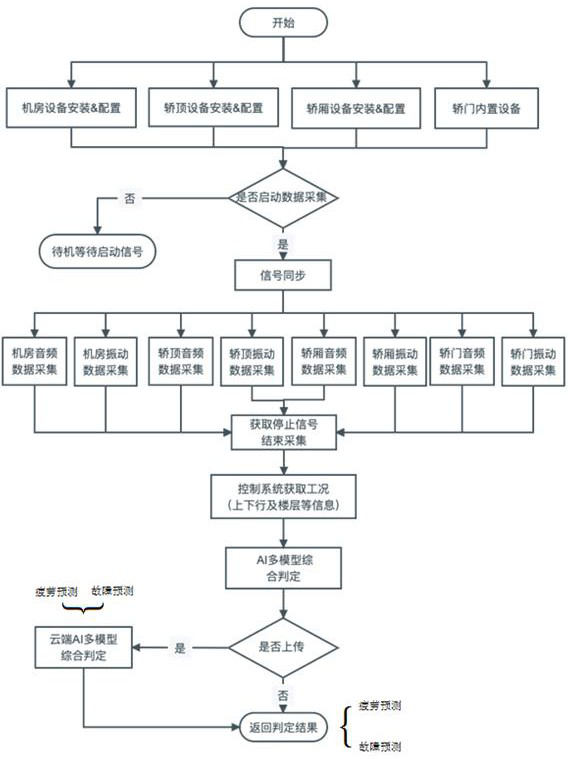

[0063] A component fatigue degree monitoring method for special machinery, especially for vertical elevators, (see attached figure 1 ), including the following steps:

[0064] Step 1, installing information data collection equipment for each component at the set position of the target equipment;

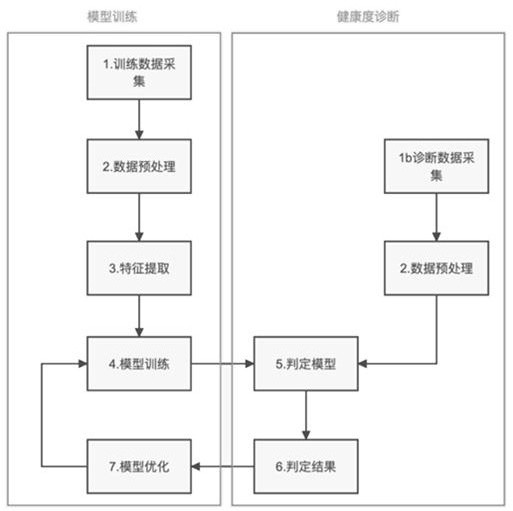

[0065] Step 2: For the target device, establish a baseline model and a fault model for the overall state of the target device on the cloud server, and perform training and iterative updates respectively;

[0066] Step 3, collecting the operating feature data of the target device and uploading it to the cloud server;

[0067] Step 4, constructing a mechanical state baseline through the baseline model on the operating characteristic data collected by the information data collection equipment on the cloud server;

[0068] Step 5: Use the established mechanical state baseline to compare and carry out fatigue warning, and use the operating characteristic data of the target equipment to ...

Embodiment 2

[0115] This embodiment is basically the same as Embodiment 1, the difference is:

[0116] The target device targeted by this embodiment is an escalator, and the target device monitored by the information data collection device includes a driving device, a step guide rail system, a handrail driving device and a safety protection device. The operation characteristic data of the collected target equipment includes the characteristic data of sound, vibration, current and temperature during the operation of the elevator, as well as the health data, sub-health data and fault data of the elevator, as well as the basic information data of the elevator and the actual operation data of the elevator. For the driving device, the information collected by the information data collection equipment includes data such as the sound, vibration, temperature, etc. of the driving host; the friction between the main drive chain and the driving wheel, and the running sound;

[0117] For the step guid...

Embodiment 3

[0121] This embodiment is basically the same as Embodiment 1, the difference is:

[0122] The target device targeted by this embodiment is a sliding amusement device, and the target device monitored by the information data collection device includes a power lifting device, a transmission device, a vehicle body, and a vehicle connection device. The operation characteristic data of the collected target equipment includes the sound and vibration data during the operation of the scooter, as well as the health data, sub-health data and fault data of the scooter, as well as basic information data and actual operation data. For the power lifting device, the information collected by the information data collection equipment includes the sound of the motor running, vibration information, and the sound of the friction of the reducer and the coupling;

[0123] For the transmission device, the information collected by the information data collection equipment includes the sound of tractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com