High-plasticity high-strength cast aluminum alloy containing nickel and copper and preparation method of high-plasticity high-strength cast aluminum alloy

A technology of casting aluminum alloy and high plasticity, applied in the field of metallurgy, can solve problems such as low strength, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] For the alloy of Example 1, the yield strength at room temperature is 153MPa, the tensile strength is 264MPa, and the elongation is 15.8%. After heat treatment (T6), the mechanical properties yield strength can reach 213MPa, the tensile strength can reach 326MPa, and the plasticity can reach 11.7%. .

Embodiment 2

[0023] Example 2 alloy, the yield strength at room temperature is 128MPa, the tensile strength is 224MPa, and the elongation is 16.3%. After heat treatment (T6), the mechanical properties yield strength can reach 178MPa, the tensile strength can reach 286MPa, and the plasticity can reach 12.8%.

Embodiment 3

[0024] In Example 3 alloy, the room temperature yield strength is 158MPa, the tensile strength is 276MPa, and the elongation is 11.7%. After heat treatment (T6), the mechanical properties yield strength can reach 235MPa, the tensile strength can reach 357MPa, and the plasticity can reach 8.3%.

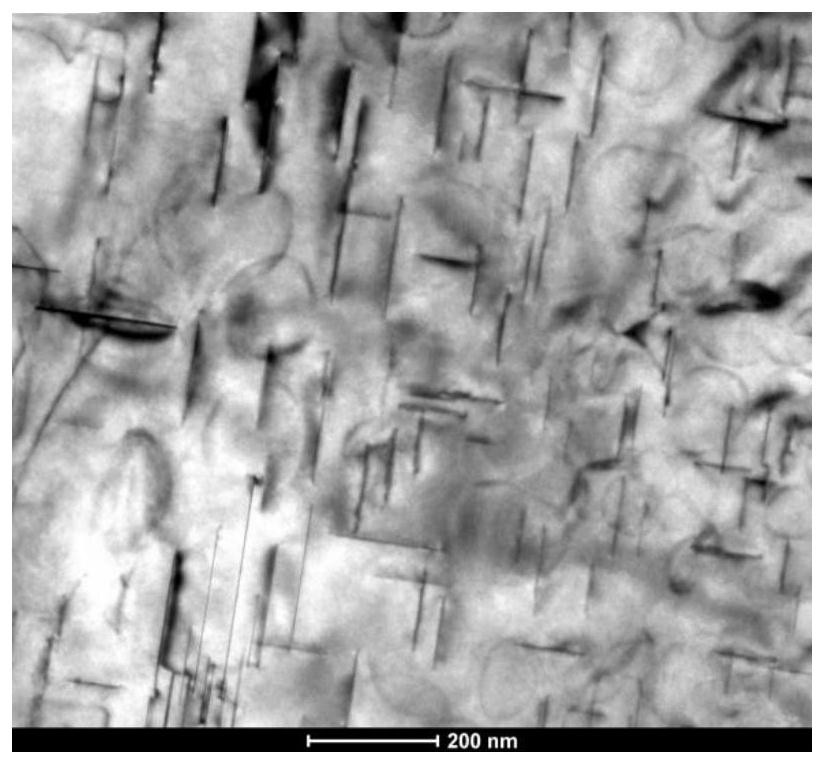

[0025] It can be seen from the properties of the alloys of the above three groups of examples that the strength of the alloy prepared by the present invention is significantly improved compared with the existing Al-Ni-based aluminum alloys. This is because the addition of the alloying element Ce can further refine the Al 3 The Ni phase has the effect of dispersion strengthening; at the same time, Ce can combine with Cu to form nanoscale precipitates, which can effectively pin dislocations and improve the strength of the alloy.

[0026] In addition, the present application also proposes a method for preparing a high-plastic and high-strength cast aluminum alloy containing nickel and copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com