Gravel pile foundation stilling pool on deep covering layer and construction method

A technology of deep covering layer and construction method, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problems of self-heavy structure of stilling pool, large foundation bearing capacity requirements, and endangering structural safety, etc., to avoid engineering volume. And the effect of increasing investment, saving engineering volume and engineering investment, and ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

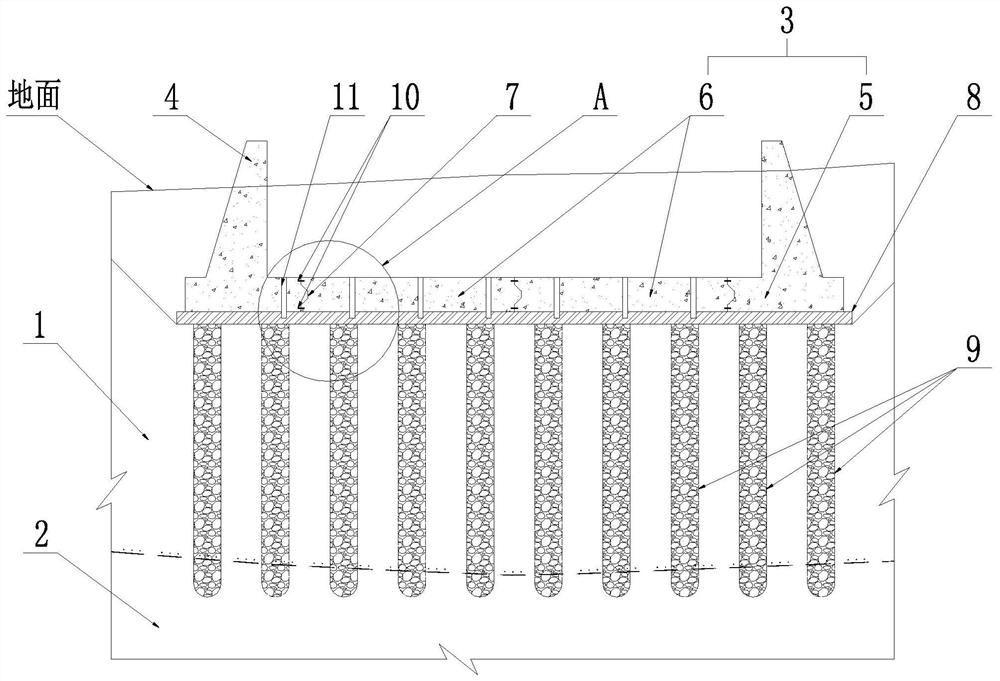

[0033] Embodiment 1 of the present invention: a gravel pile foundation stilling pool on a deep covering layer, including a covering layer 1, a bedrock layer 2, a bottom plate 3 and a side wall 4, and the bottom plate 3 includes two side bottom plates 5 and A plurality of middle bottom plates 6, a plurality of middle bottom plates 6 are placed between two side bottom plates 5, the bottom of the side wall 4 is connected to the upper surface of the side bottom plates 3, and a transverse There is also a transverse joint 7 between two adjacent middle bottom plates 6, a concrete cushion 8 is provided on the lower surface of the bottom plate 3, and a gravel pile 9 is arranged on the lower surface of the concrete cushion 8, and the gravel pile 9 runs through Covering layer 1, the pile bottom of gravel pile 9 is submerged into bedrock layer 2, and cover layer 1 is positioned at the top of bedrock layer 2.

Embodiment 2

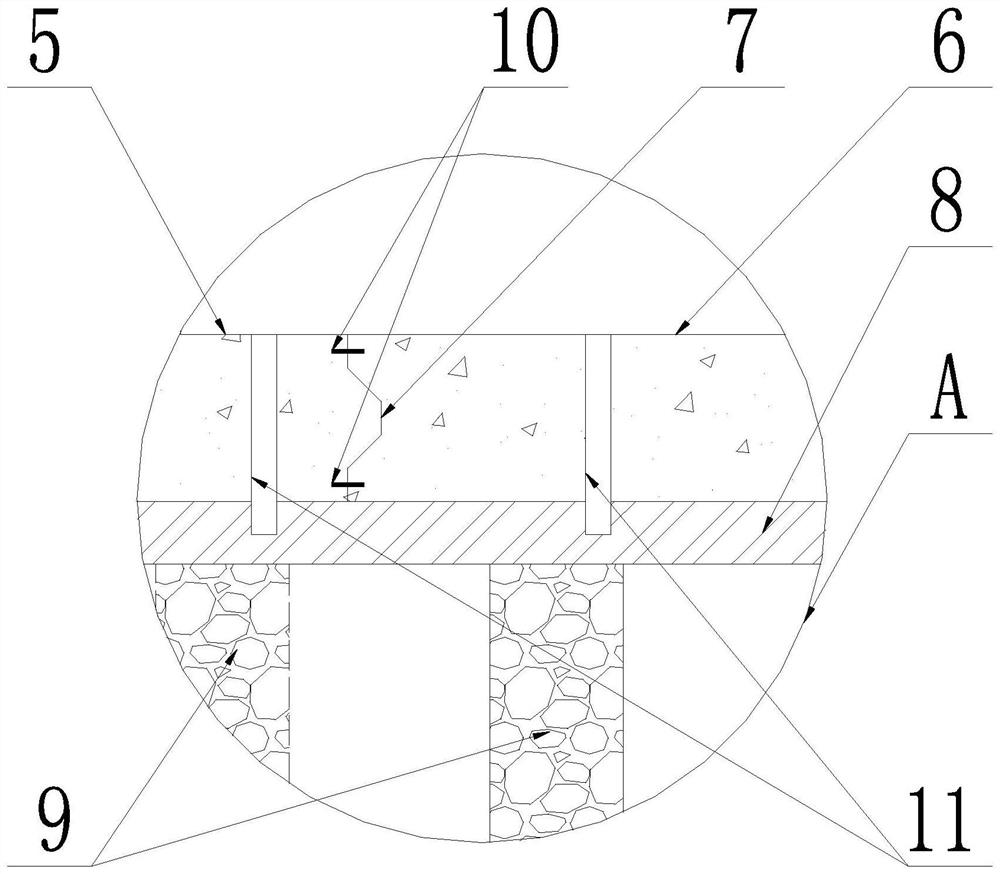

[0034]Embodiment 2 of the present invention: a gravel pile foundation stilling pool on a deep covering layer, including a covering layer 1, a bedrock layer 2, a bottom plate 3 and a side wall 4, and the bottom plate 3 includes two side bottom plates 5 and A plurality of middle bottom plates 6, a plurality of middle bottom plates 6 are placed between two side bottom plates 5, the bottom of the side wall 4 is connected to the upper surface of the side bottom plates 3, and a transverse There is also a transverse joint 7 between two adjacent middle bottom plates 6, a concrete cushion 8 is provided on the lower surface of the bottom plate 3, and a gravel pile 9 is arranged on the lower surface of the concrete cushion 8, and the gravel pile 9 runs through Covering layer 1, the pile bottom of gravel pile 9 submerges into the bedrock layer 2, and the covering layer 1 is located on the upper part of the bedrock layer 2; the transverse joint 7 is provided with a water stop 10.

Embodiment 3

[0035] Embodiment 3 of the present invention: a gravel pile foundation stilling pool on a deep covering layer, including a covering layer 1, a bedrock layer 2, a bottom plate 3 and a side wall 4, and the bottom plate 3 includes two side bottom plates 5 and A plurality of middle bottom plates 6, a plurality of middle bottom plates 6 are placed between two side bottom plates 5, the bottom of the side wall 4 is connected to the upper surface of the side bottom plates 3, and a transverse There is also a transverse joint 7 between two adjacent middle bottom plates 6, a concrete cushion 8 is provided on the lower surface of the bottom plate 3, and a gravel pile 9 is arranged on the lower surface of the concrete cushion 8, and the gravel pile 9 runs through Covering layer 1, the pile bottom of gravel pile 9 is submerged into the bedrock layer 2, and the covering layer 1 is located on the upper part of the bedrock layer 2; the transverse joint 7 is provided with a water stop 10; the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com