Multi-degree-of-freedom connecting device

A technology of connection device and degree of freedom, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems that the center of the flow channel cannot be aligned, the time and cost of disassembly and assembly will increase, and the investment of considerable manpower and time will be achieved. The effect of reducing risk level and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

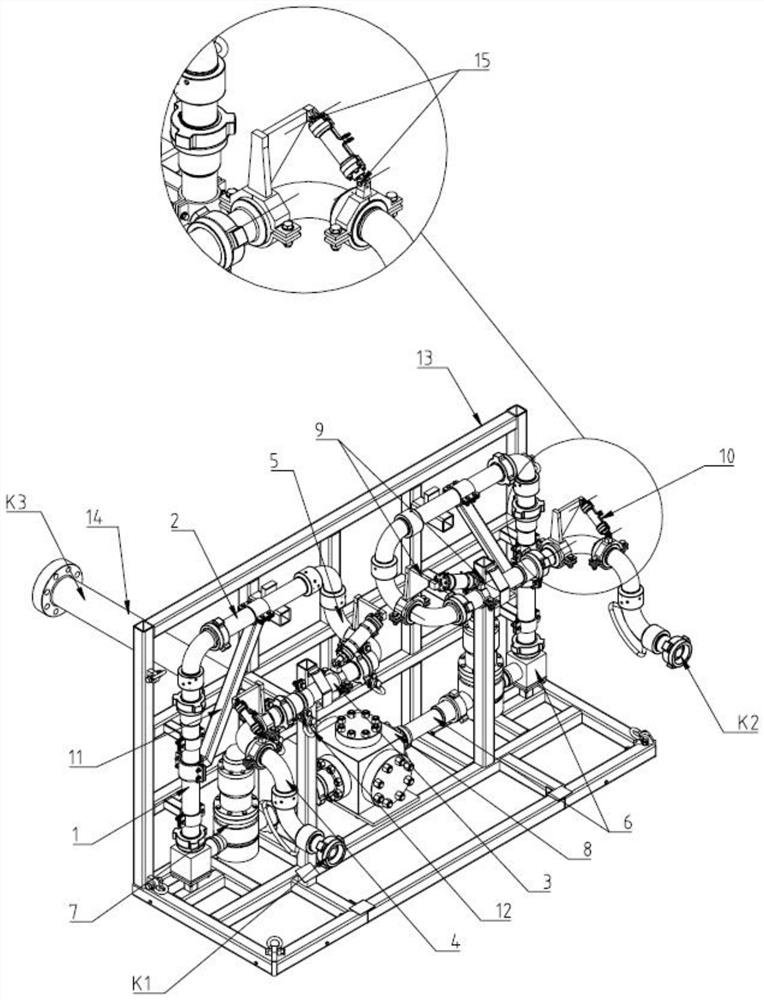

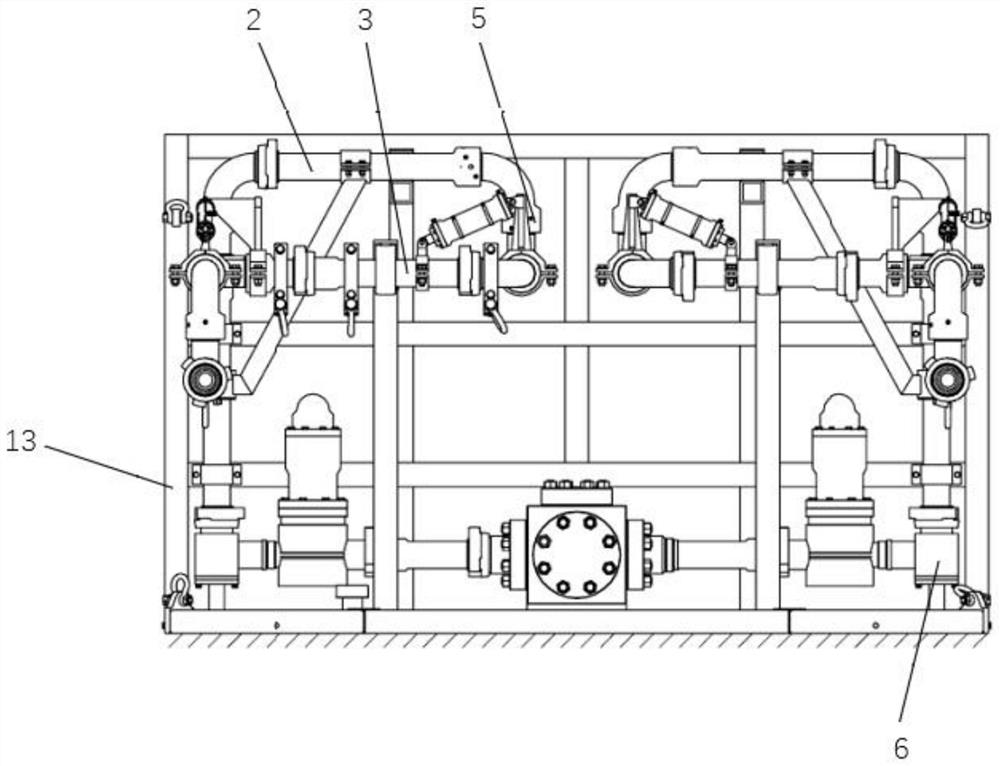

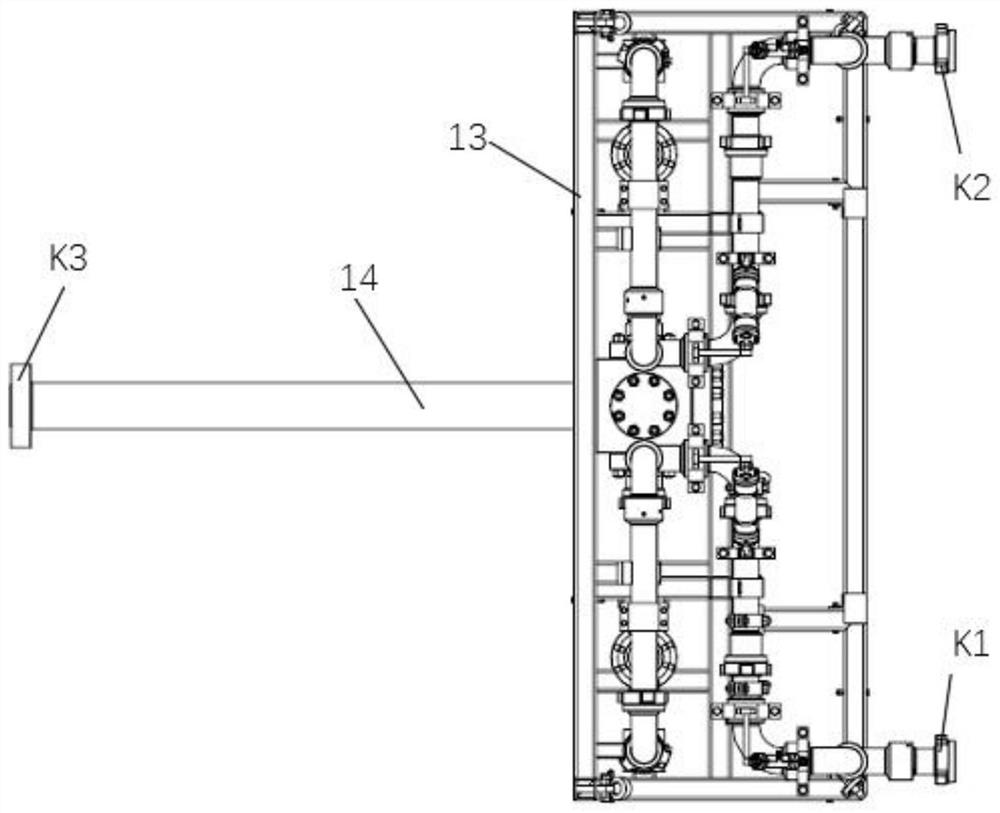

[0022] This embodiment provides a specific structure of a multi-degree-of-freedom connection device, such as Figure 1-3 As shown, including frame 13, multi-free movable arm, high-pressure pipeline 6, cock valve 7, diverter 8, flange pipe 14, wherein:

[0023] Multiple freely movable arms, high pressure pipeline 6, cock valve 7, diverter 8 and flange pipe 14 are all installed on the frame 13;

[0024] The multi-free movable arm is assembled by the first pipe body 1, the main movable pipe body 2, the secondary movable pipe body 3, the tail pipe body 4 and the transition pipe body 5, the head pipe body 1, the main movable pipe body 2, the transition pipe body 5, the secondary The movable pipe body 3 and the tail pipe body 4 are connected end to end to form multiple free movable arms;

[0025] The multi-free movable arm is connected to the high-pressure pipeline 6 through the plug valve 7 to form a movable fluid channel, and the flange tube 14 independently forms a fixed fluid c...

Embodiment 2

[0027] This embodiment provides a specific structure of a multi-degree-of-freedom connection device, such as Figure 1-3 As shown, including frame 13, multi-free movable arm, high-pressure pipeline 6, cock valve 7, diverter 8, flange pipe 14, wherein:

[0028] Multiple freely movable arms, high pressure pipeline 6, cock valve 7, diverter 8 and flange pipe 14 are all installed on the frame 13;

[0029] The multi-free movable arm is assembled by the first pipe body 1, the main movable pipe body 2, the secondary movable pipe body 3, the tail pipe body 4 and the transition pipe body 5, the head pipe body 1, the main movable pipe body 2, the transition pipe body 5, the secondary The movable pipe body 3 and the tail pipe body 4 are connected end to end to form multiple free movable arms;

[0030] The multi-free movable arm is connected to the high-pressure pipeline 6 through the plug valve 7 to form a movable fluid channel, and the flange tube 14 independently forms a fixed fluid c...

Embodiment 3

[0037] This embodiment provides a specific structure of a multi-degree-of-freedom connection device, such as Figure 1-3 As shown, including frame 13, multi-free movable arm, high-pressure pipeline 6, cock valve 7, diverter 8, flange pipe 14, wherein:

[0038] The multi-free movable arm, the high-pressure pipeline 6, the plug valve 7, the diverter 8 and the flange pipe 14 are all installed on the frame 13, and a flexible pad is arranged between the right-angle joint of the high-pressure pipeline 6 and the frame 13;

[0039] The multi-free movable arm is assembled by the first pipe body 1, the main movable pipe body 2, the secondary movable pipe body 3, the tail pipe body 4 and the transition pipe body 5, the head pipe body 1, the main movable pipe body 2, the transition pipe body 5, the secondary The movable pipe body 3 and the tail pipe body 4 are connected end to end to form multiple free movable arms;

[0040] The multi-free movable arm is connected to the high-pressure pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com