Electric sealing method of bridge type eccentric dispensing

An electric and bridge-type technology, applied in the direction of earthwork drilling, measurement, wellbore/well components, etc., can solve the problems of easy pulling of the sealing section cup, low work efficiency, heavy steel wire load, etc., so as to reduce the labor force of workers Intensity, on-site data acquisition is real, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

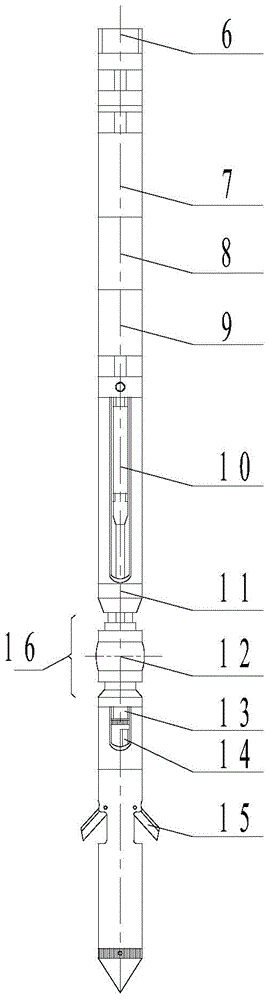

[0026] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

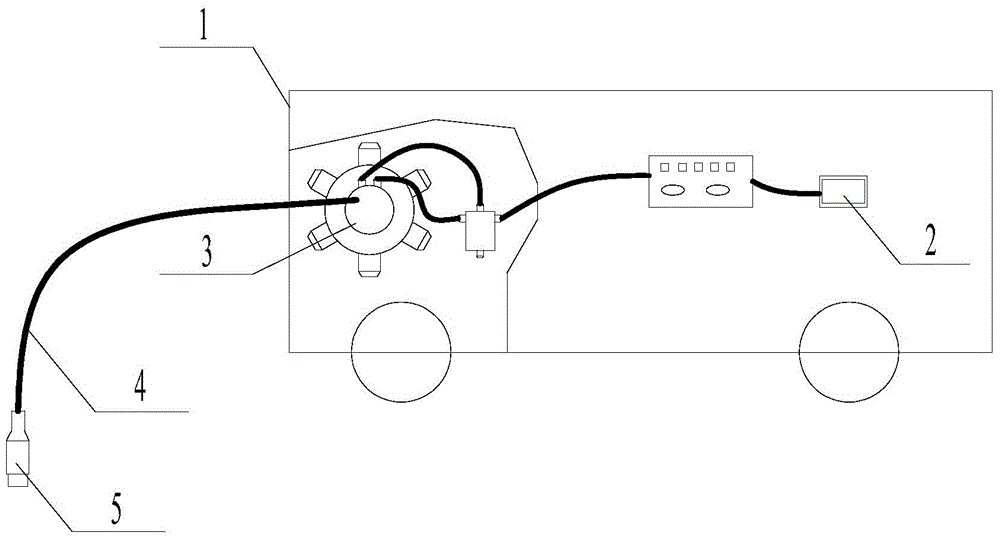

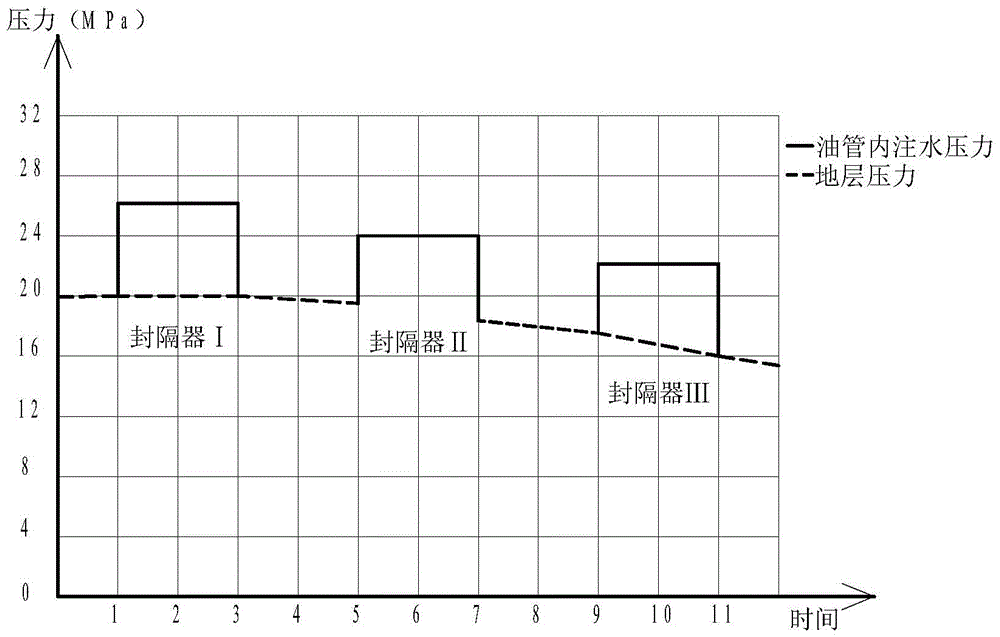

[0027] The electric sealing inspection method of the bridge-type eccentric injection of the present invention can realize the electric setting, inspection and unsealing of the sealing section of the sealing inspection instrument, and effectively reduce the risk of downhole accidents such as jamming and dropping of the sealing inspection instrument and damage and falling off of the sealing section during operation. , to avoid frequent lifting and lowering of the steel wire, and the sealing performance of the packers in different injection intervals can be verified layer by layer in one trip, and the seal inspection data can be directly read on the ground and monitored in real time, ensuring the accuracy of the seal inspection data and increasing the magnetic field. The positioning function realizes the precise positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com