An intelligent sewage treatment system

A sewage treatment system and intelligent technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high replacement and maintenance costs, unsatisfactory phosphorus removal effect, and aggravating membrane filaments. breakage and other problems, to achieve a significant effect of phosphorus removal, avoid frequent lifting, and reduce the rate of wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

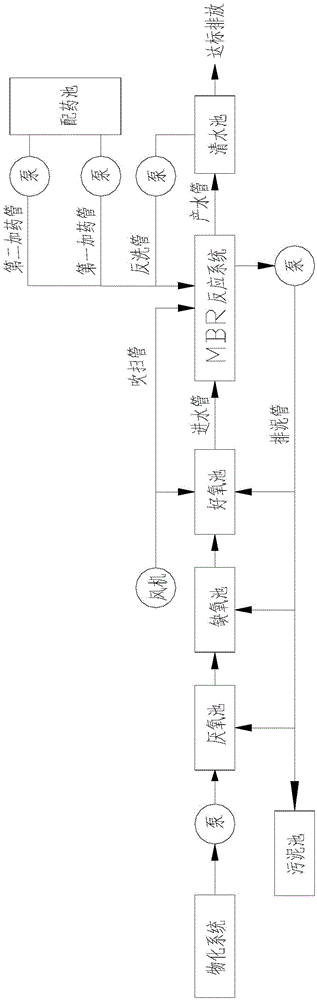

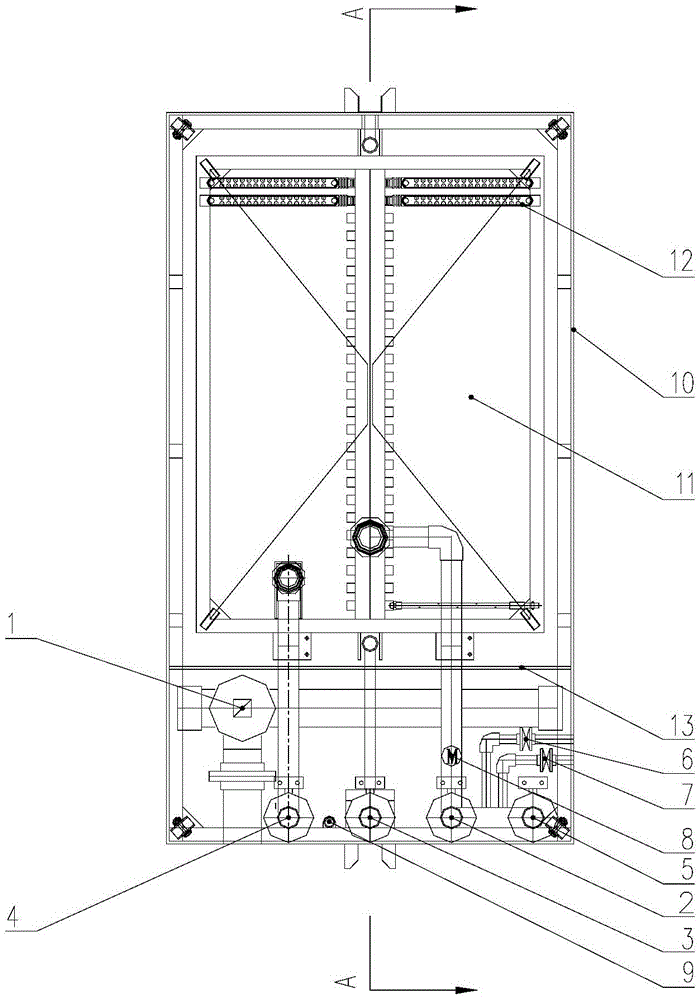

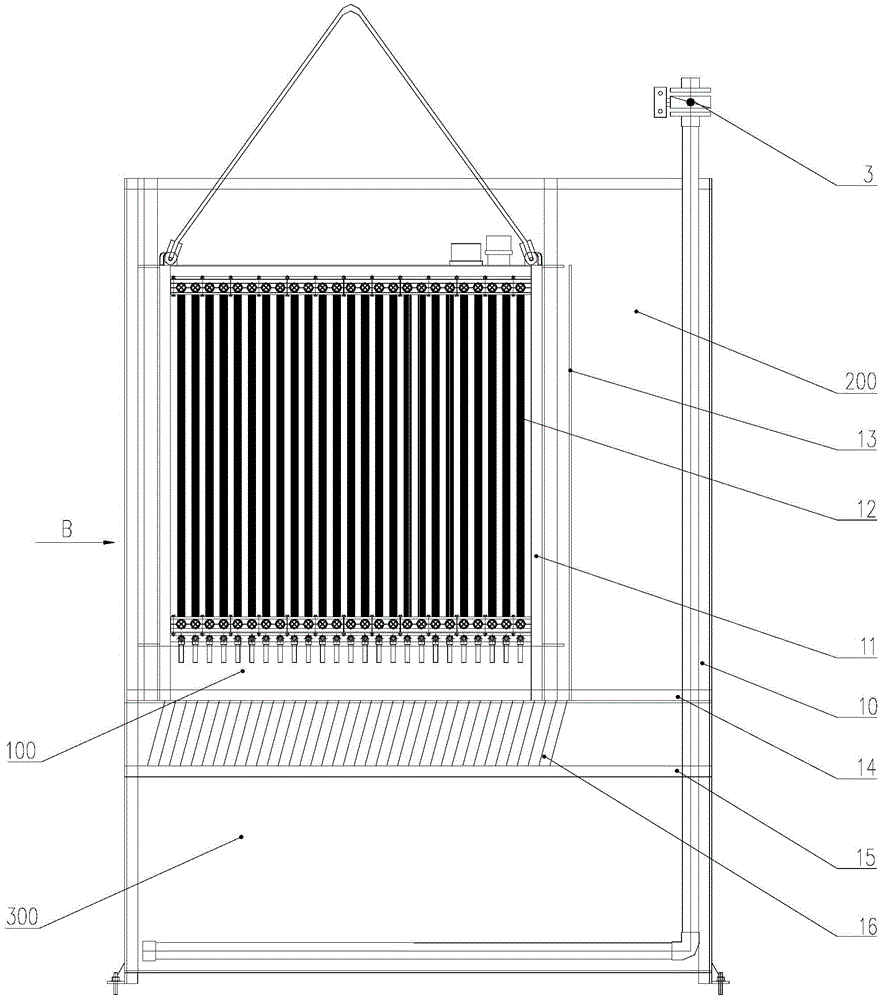

[0022] Combine below Figure 1~4 The technical solutions of the present invention are further described through specific implementation methods.

[0023] An intelligent sewage treatment system, including a physical and chemical system, an anaerobic tank, anoxic tank, and aerobic tank connected in sequence through pipelines, an MBR reaction system connected to the aerobic tank through a water inlet pipe, and a product installed on the upper part of the MBR reaction system. The water pipe, the backwash pipe and the clear water tank connected to the MBR reaction system; the lower end of the MBR reaction system is connected to the mud discharge pipe, the MBR reaction system is connected to the fan through the blowing pipe, and the MBR reaction system is also connected to the dispensing tank through the dosing pipe; the water inlet pipe , water production pipe, mud discharge pipe, purge pipe, backwash pipe and dosing pipe are respectively provided with water inlet valve 1, water pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com