Auxiliary equipment for aquarium production

A technology for production assistance and aquariums, which is applied in the direction of mechanical equipment, material gluing, and connecting components. It can solve the problems of dislocation, drop, and dislocation of inclined edges, etc., and achieve the effect of saving time and preventing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An aquarium production aid such as Figure 1-10 As shown, it includes a bottom frame 1, a stage 2, a limit frame 3, a gantry frame 4, a fixing frame 5, an assembly component and a clamping and pressing component; The limit frame 3 is fixedly connected to the upper side of the stage 2; the gantry frame 4 is fixedly connected to the bottom frame 1; the fixed frame 5 is fixedly connected to the upper part of the gantry frame 4; the assembly component is connected to the bottom frame 1; are connected; the lower side of the fixed frame 5 is equipped with a clamping and pressing assembly.

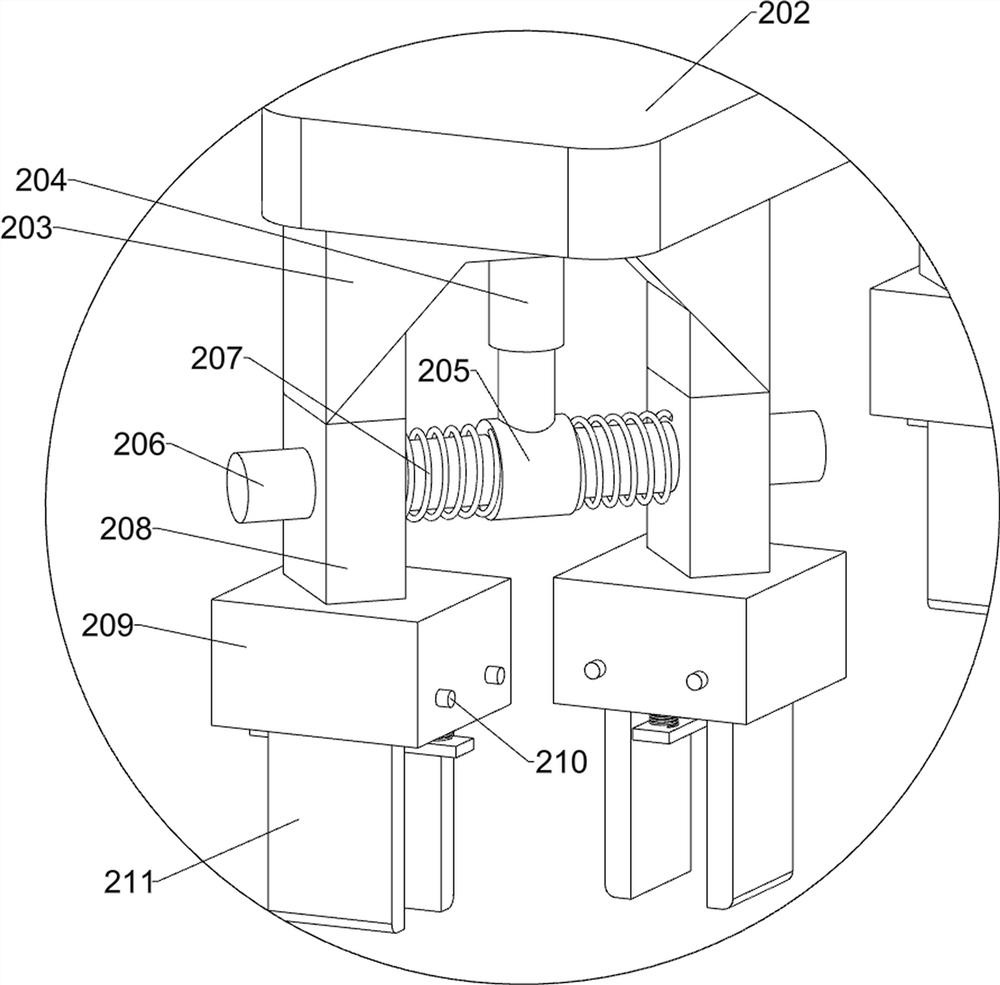

[0035] The assembly assembly includes a first electric push rod 101, a U-shaped frame 102, a first fixed rod 103, a transmission plate 104, a limit slide rail 105, a second fixed rod 106, a fixed seat 107, a second electric push rod 108, an electric Clip 109, third fixed rod 110, sleeve 111, mounting plate 112, first electric slide rail 113, first electric slide block 114, first support p...

Embodiment 2

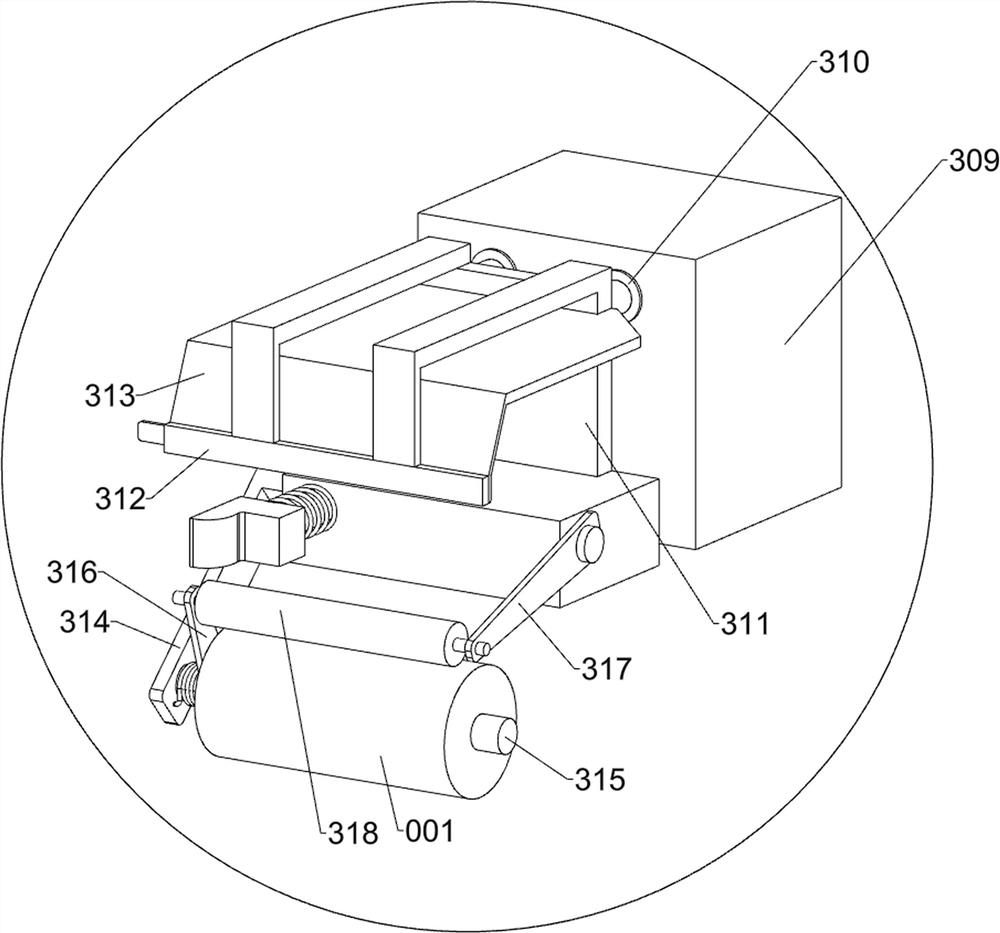

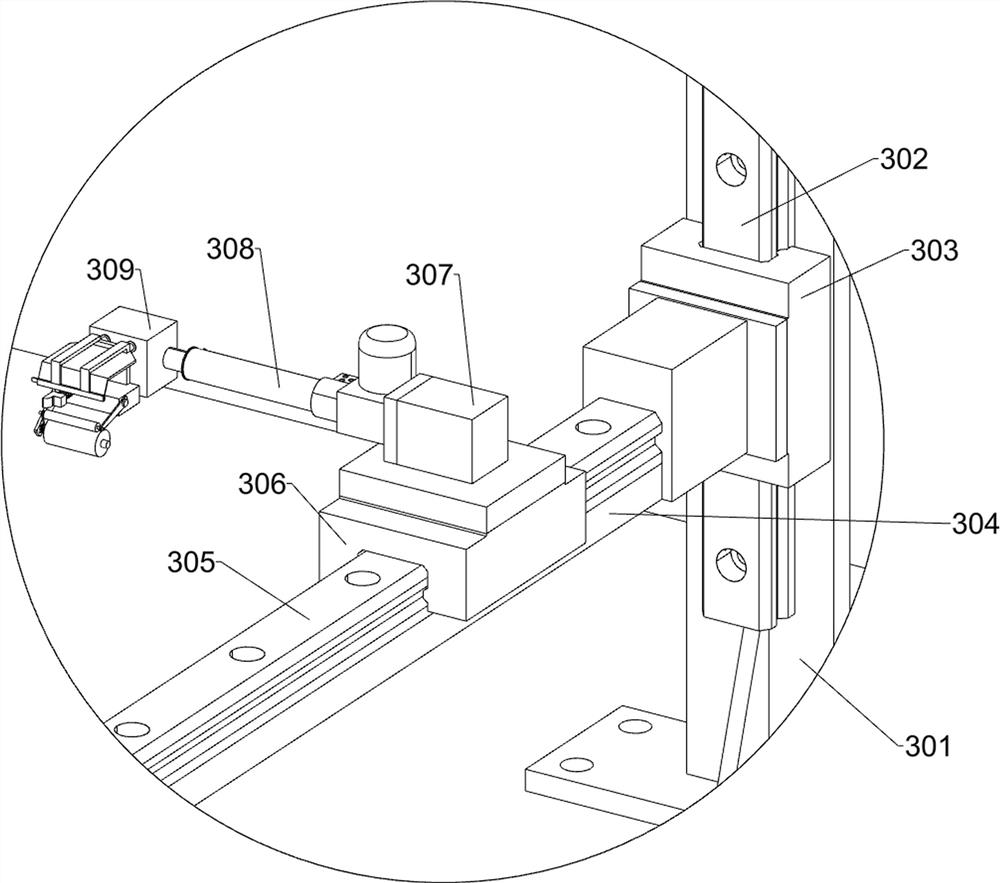

[0043] On the basis of Example 1, such as figure 1 with Figure 11-14 As shown, an edge banding assembly is also included. The edge banding assembly is installed on the upper side of the chassis 1. The edge banding assembly includes a second support plate 301, a second electric slide rail 302, a second electric slide block 303, and a first fixed plate. 304, the third electric slide rail 305, the third electric slider 306, the first fixed block 307, the fourth electric push rod 308 and the fitting unit; A second support plate 301; the opposite sides of the two second support plates 301 on the left are each fixedly connected with a second electric slide rail 302; Slider 303; a first fixed plate 304 is fixed between the two second electric sliders 303 on the left; a third electric slide rail 305 is fixed on the first fixed plate 304 on the left; two second electric slide rails 305 are fixed on the right A second electric slide rail 302 is fixedly connected to the opposite sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com