Semiconductor refrigeration chip test tool

A technology for cooling chips and testing tooling, applied in the direction of thermal development of materials, etc., can solve problems such as time-consuming, poor accuracy, and time-consuming testing process, and achieve convenient installation and disassembly, convenient disassembly and assembly, and short testing time. Effect

Pending Publication Date: 2022-02-18

苏州丁冬科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In practical applications, it is necessary to select different semiconductor cooling chips for different use environments and equipment. However, there are currently no relevant instrument test data for reference in the selection of semiconductor cooling chips, such as ceramic cooling chips, in the market. It can only be installed directly for actual measurement, which takes a long time and has poor accuracy

When testing the cooling chip with the test tool, because the conventional tooling is a one-time test structure, it is difficult to disassemble and assemble the cooling chip, resulting in a long and troublesome test process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

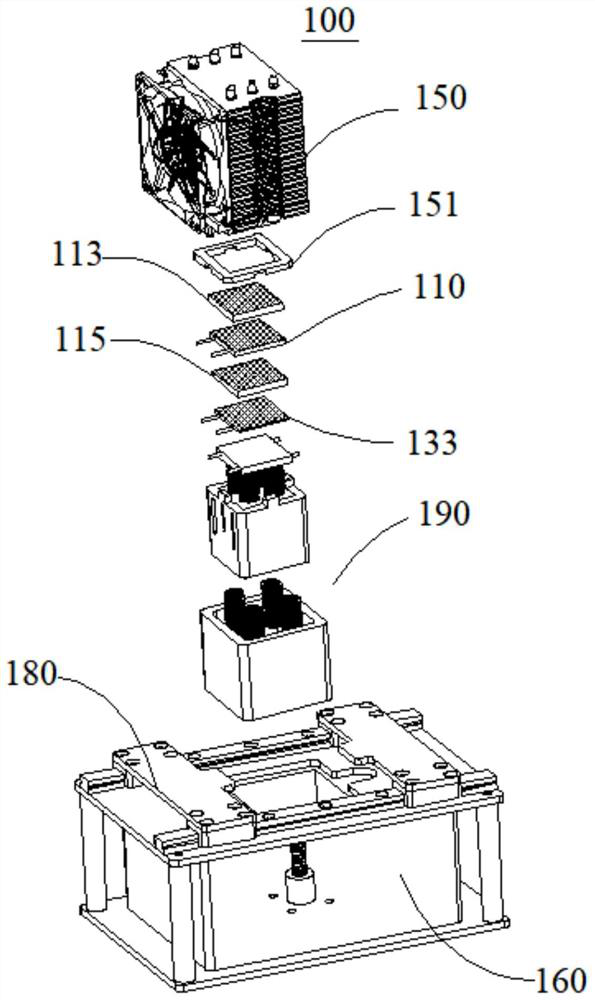

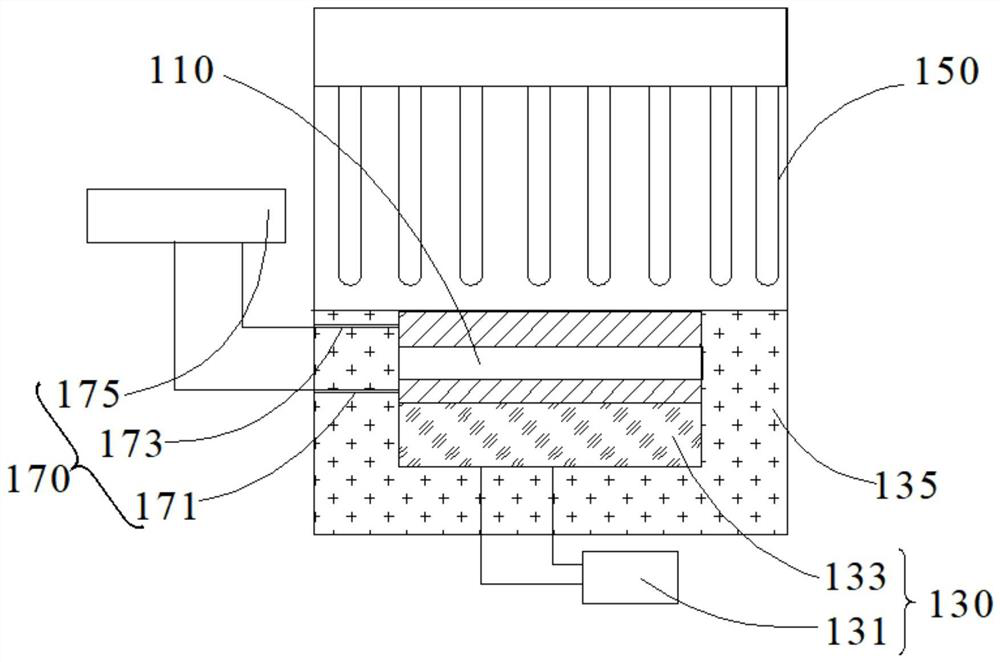

[0037] see in conjunction Figure 1 to Figure 4 , this embodiment provides a semiconductor cooling chip testing tool 100, which can realize the performance test of the semiconductor cooling chip 110, and can easily disassemble and assemble the cooling chip 110, and the test time is short and the accuracy is good.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The embodiment of the invention provides a semiconductor refrigeration chip test tool, and relates to the technical field of semiconductor refrigeration, the semiconductor refrigeration chip test tool comprises a positioning frame, a limiting module, a heating module and a heat dissipation module; the limiting module is arranged on the positioning frame, then the heating module is arranged on the limiting module, a cooling module is detachably connected to the positioning frame, the refrigeration chip is placed on the heating module, meanwhile, the cooling module is used for being pressed on the refrigeration chip, and the refrigeration chip, the heating module and the limiting module are pressed into a whole, so that the refrigeration chip is fixed. When the refrigeration chip needs to be disassembled or replaced, the refrigeration chip can be exposed outside only by disassembling the heat dissipation module, so that the refrigeration chip is very convenient to assemble and disassemble. Compared with the prior art, the performance test of the semiconductor refrigeration chip can be realized, the refrigeration chip can be conveniently disassembled and assembled, the test time is short, and the precision is good.

Description

technical field [0001] The invention relates to the field of semiconductor refrigeration technology, in particular to a semiconductor refrigeration chip testing tool. Background technique [0002] Most of the traditional mechanical refrigeration equipment uses freon refrigeration, but the freon refrigeration method is polluting, and mechanical refrigeration has defects such as large volume, many system parts, large power consumption, need to add refrigerant (refrigerant), and limited refrigeration limit temperature. Therefore, in some high-end manufacturing fields, mechanical refrigeration can no longer meet industrial requirements. [0003] At present, with the development of semiconductor refrigeration technology, the use of semiconductor refrigeration chips for cooling is gradually being widely used. Semiconductor refrigeration chips rely on direct current to absorb heat and release heat at both ends of the couple to achieve the purpose of cooling and heating, which is in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N25/20

CPCG01N25/20

Inventor 黄永华钱波李皇

Owner 苏州丁冬科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com