Heat dissipation system of electronic equipment

A heat dissipation system and technology for electronic equipment, applied to structural parts of electrical equipment, electrical components, electrical digital data processing, etc., can solve problems such as poor appearance quality, large airflow resistance, and non-directional airflow, achieving low noise, Overall energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

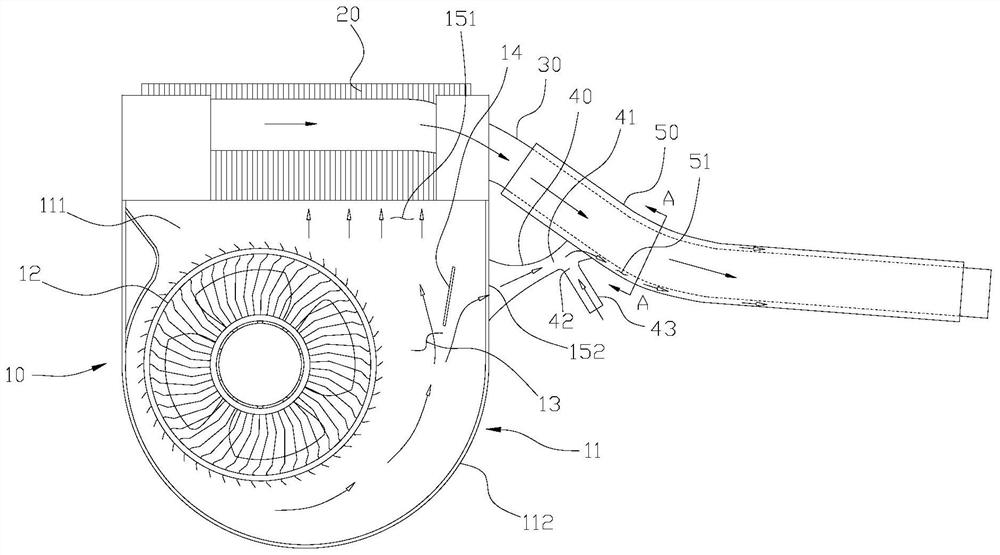

[0029] Such as figure 1 As shown, the embodiment of the present invention discloses a heat dissipation system, the heat dissipation system is installed in the shell of the system end of the notebook computer (a kind of electronic equipment), and the heat dissipation system includes: a heat dissipation fan 10, a heat dissipation fin 20 ( As a heat dissipation component) and heat pipe 30.

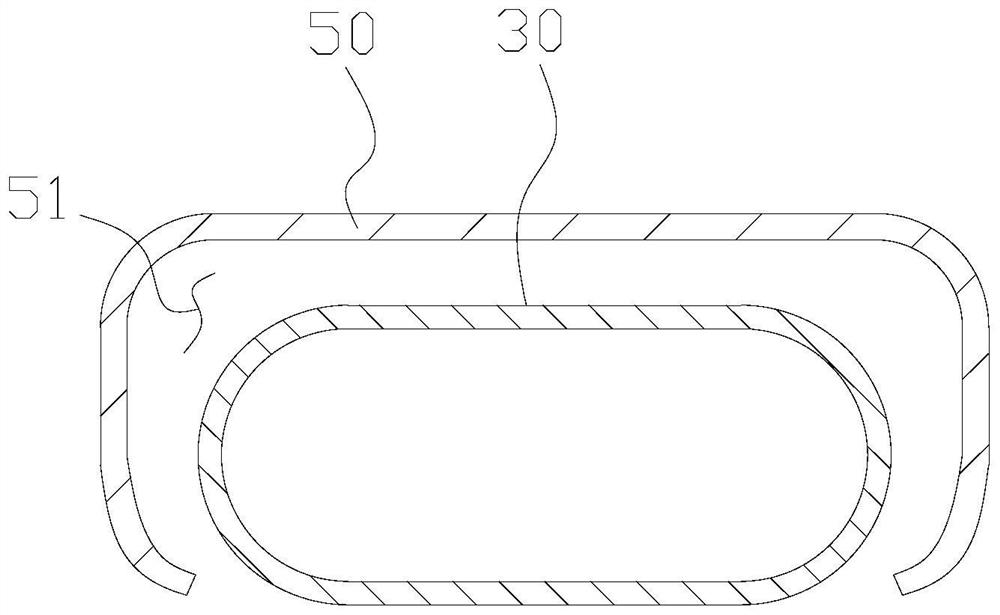

[0030] The heat dissipation fin 20 is arranged at the main air outlet 151 of the heat dissipation fan 10, the root of the heat conduction pipe 30 is connected to the heat dissipation fin 20, and the far end of the heat conduction pipe 30 stretches out of the shell, and the heat dissipation fin 20 is close to the functional parts ( Such as CPU),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com