Temperature measuring mechanism of ring main unit

A ring network cabinet and connection mechanism technology, which is applied in the field of ring network cabinets, can solve problems such as errors that are prone to occur, and achieve the effects of reducing losses, improving temperature measurement accuracy, and avoiding measurement failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

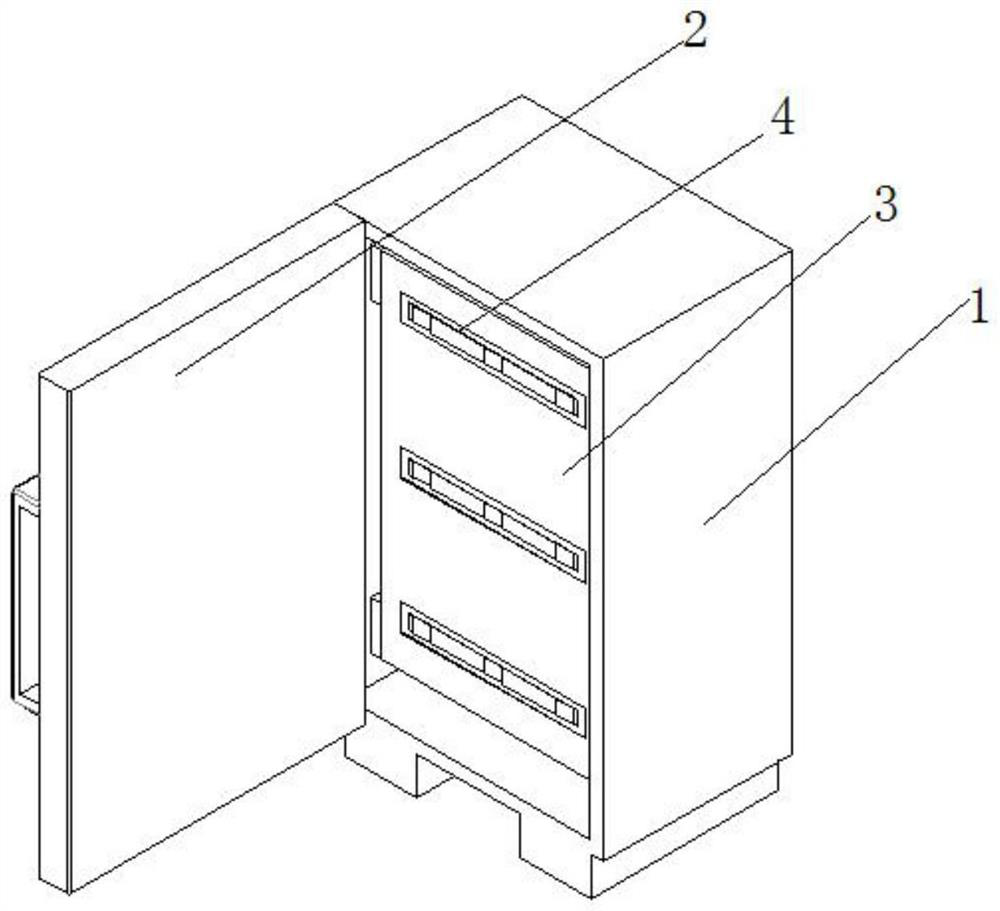

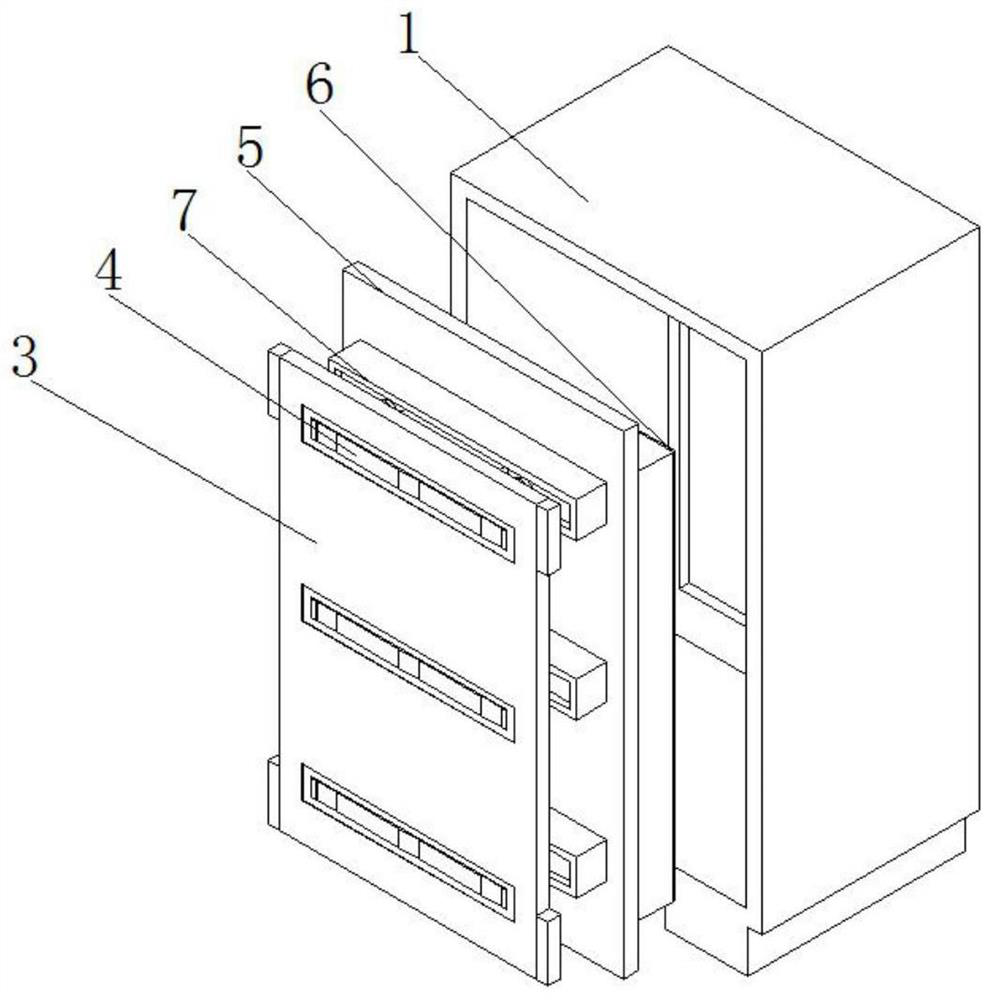

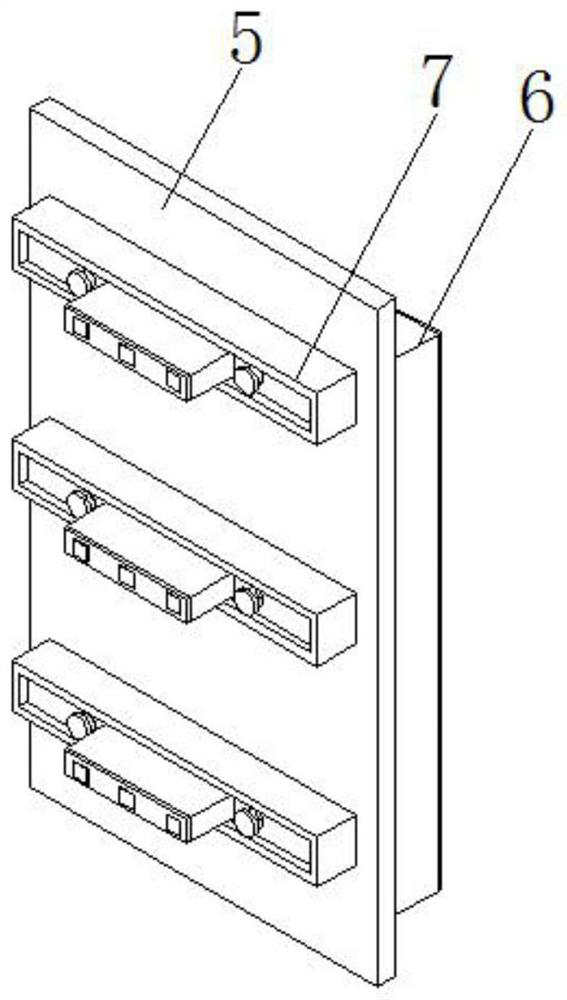

[0029] Embodiment 1, with reference to Figure 1-8 , the temperature measuring mechanism of the ring network cabinet, including the cabinet body 1, the outer wall of one side of the cabinet body 1 is movably connected with the cabinet door 2, the inner wall of the cabinet body 1 is fixedly connected with the installation plate 3, and the outer wall of one side of the installation plate 3 is provided with Rectangular slot, the inner wall of the rectangular slot is fixedly connected with the mounting seat 4, the inner wall of the cabinet body 1 is fixedly connected with the partition 5, and the outer wall of one side of the partition 5 is fixedly connected with the heat conduction mechanism 7, one end of the heat conduction mechanism 7 and the installation plate 3 In contact with each other, the outer wall on the other side of the partition 5 is fixedly connected with the detection box 6, the heat conduction mechanism 7 includes a heat conduction seat 8, the inner wall of the hea...

Embodiment 2

[0032] Embodiment 2, with reference to Figure 1-7 And 9, the temperature measuring mechanism of the ring network cabinet, including the cabinet body 1, the outer wall of one side of the cabinet body 1 is movably connected with the cabinet door 2, the inner wall of the cabinet body 1 is fixedly connected with the installation plate 3, and the outer wall of one side of the installation plate 3 is There is a rectangular slot, the inner wall of the rectangular slot is fixedly connected with the installation seat 4, the inner wall of the cabinet body 1 is fixedly connected with the partition 5, and the outer wall of one side of the partition 5 is fixedly connected with the heat conduction mechanism 7, one end of the heat conduction mechanism 7 and the installation The plates 3 are in contact with each other, and the outer wall on the other side of the partition 5 is fixedly connected with a detection box 6. The heat conduction mechanism 7 includes a heat conduction seat 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com