Unpowered portable heavy-load piling car

A technology of stacking trucks and power, applied in the field of non-powered portable heavy-duty stacking trucks, can solve problems such as inability to walk freely, heavy inconvenience, and inability to extend the fork sideways to pick up and release goods, etc., to achieve flexible and convenient use, Rapid deployment, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

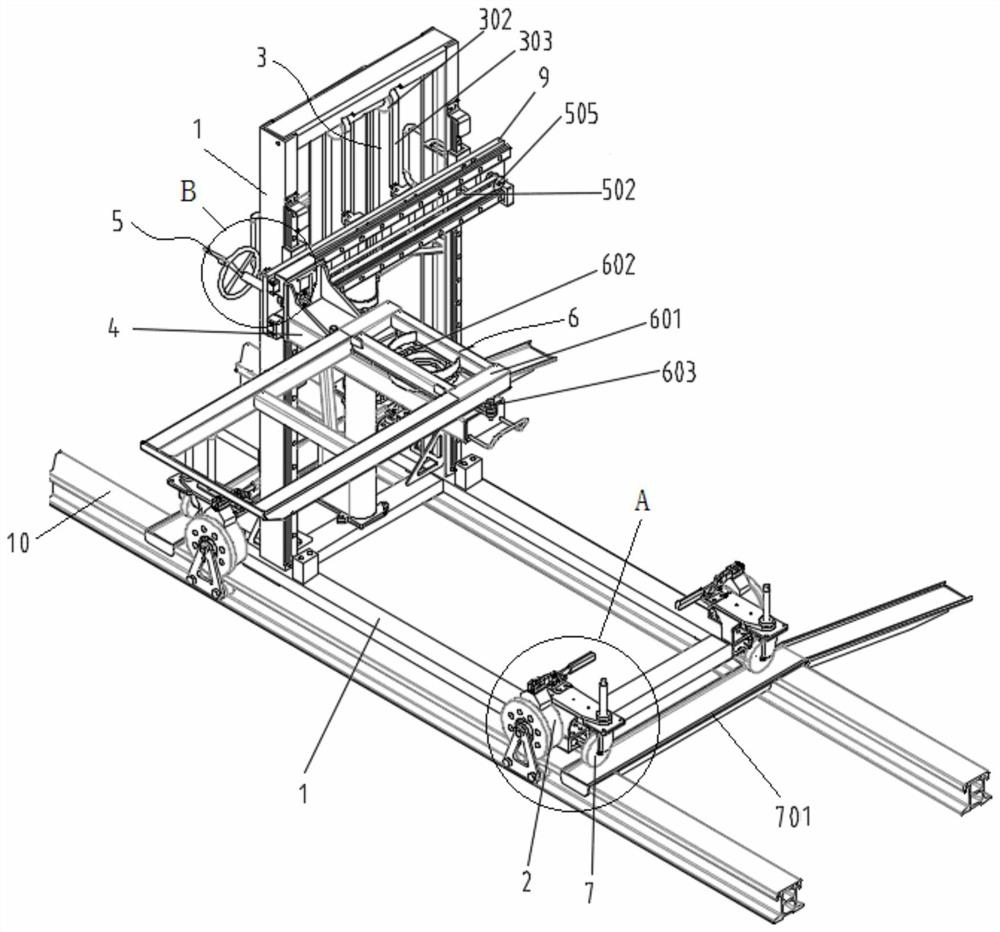

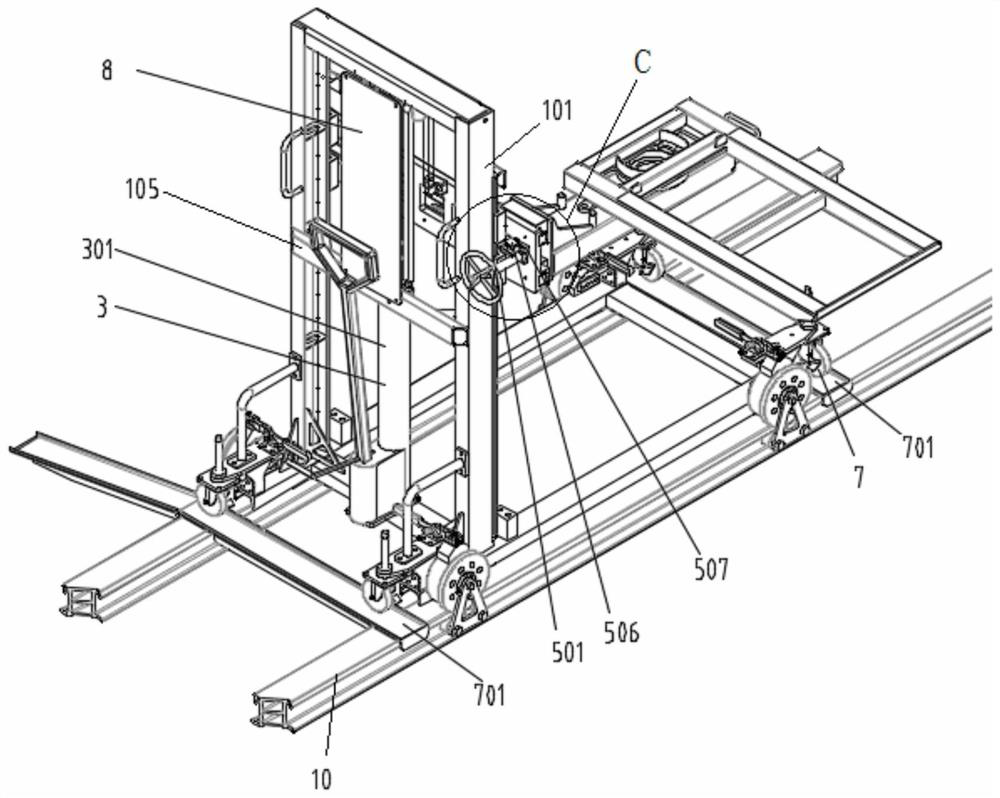

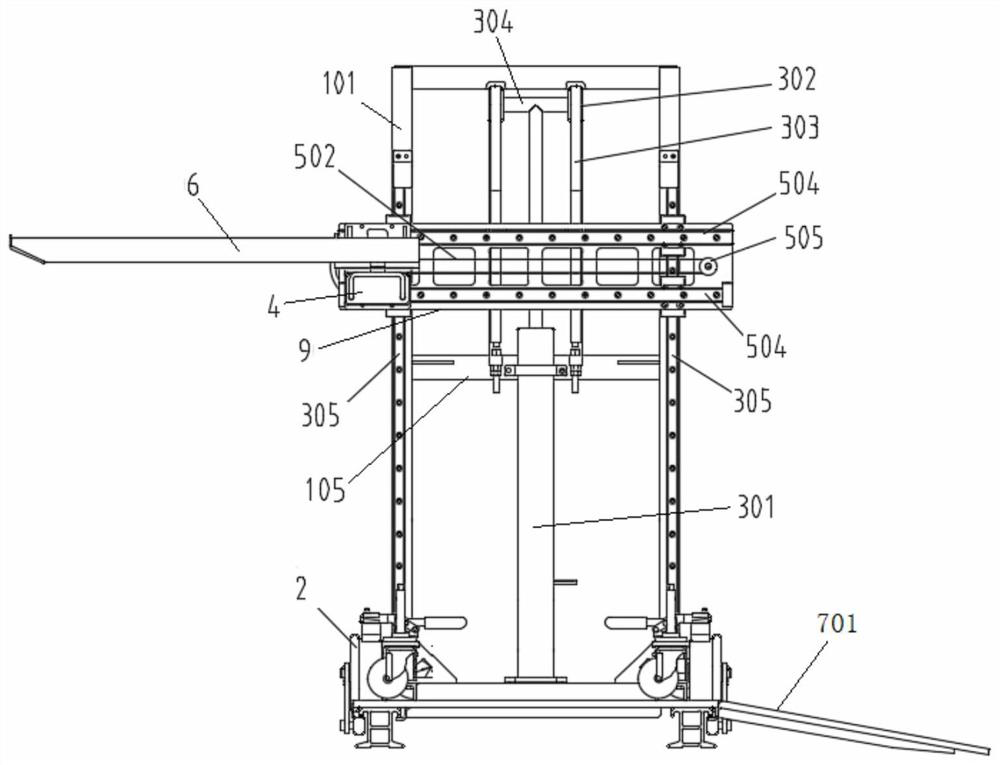

[0029] Such as Figure 1-9 As shown, the present invention includes a vehicle frame 1, a lifting mechanism 3, a lifting slide plate 9, a translation drive mechanism 5, a translation slide table 4, a rotary fork 6, a traveling wheel assembly 2, a reversing wheel assembly 7 and a track 10, and the lifting mechanism 3 and the lifting slide plate 9 are all arranged on the vehicle frame 1, and the lifting slide plate 9 is driven up and down by the lifting mechanism 3, and the translation drive mechanism 5 and the translation slide table 4 are all arranged on the lifting slide plate 9, and the The translation slide table 4 is driven to translate by the translation drive mechanism 5, a rotating fork 6 is provided on the translation slide table 4, and a road wheel assembly 2 is provided at the front and rear ends of both sides of the vehicle frame 1, and as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com