Electrolyte solution for lithium secondary battery and lithium secondary battery including the same

A lithium secondary battery and electrolyte technology, applied in secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of increased battery internal resistance, increased electrode thickness, etc. The effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 5

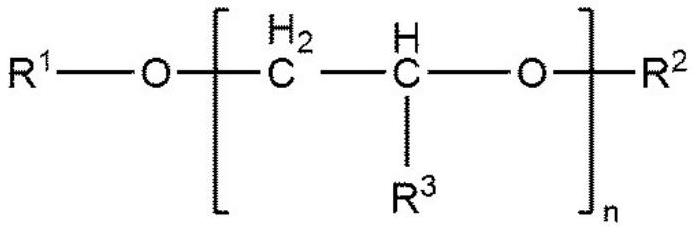

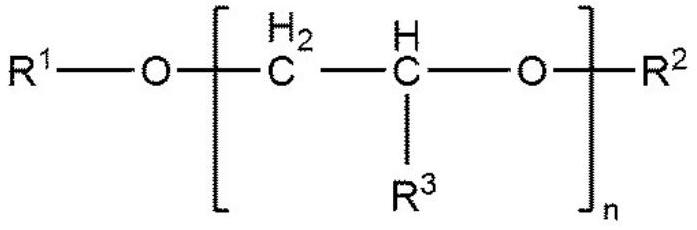

[0158] With respect to the basic electrolytic solution of Comparative Example 1, polyethylene glycol dimethyl ether with a weight average molecular weight of about 1000, 2000, 5000, 10000 and 20000 was added so that it was 1% by weight of the total weight of the electrolytic solution, thereby preparing The electrolyte solution of embodiment 1 to embodiment 5.

manufacture example

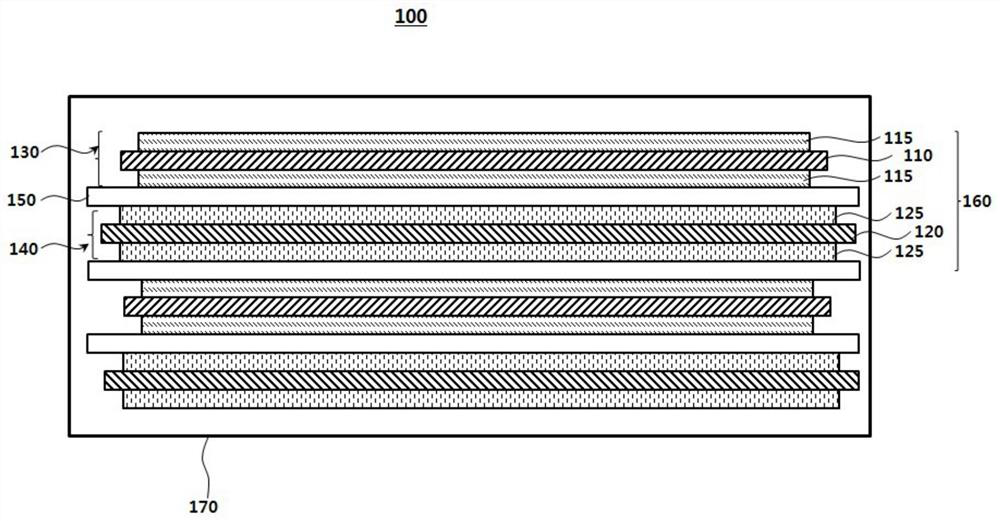

[0159] Manufacturing example: Manufacturing of lithium secondary batteries

[0160] Mix 92% by weight Li[Ni 0.6 co 0.2 mn 0.2 ]O 2 and Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 The positive electrode active material, 3% by weight polyvinylidene fluoride (PVDF) binder and 5% by weight carbon black conductive material were mixed to prepare positive electrode slurry.

[0161] The positive electrode slurry was uniformly coated on an aluminum foil having a thickness of 15 μm, and dried and pressed to manufacture a positive electrode.

[0162] 97% by weight of negative electrode active material mixed with artificial graphite and natural graphite at a weight ratio of 7:3, 1% by weight of styrene-butadiene rubber (SBR) binder and 2% by weight of carboxymethylcellulose (CMC) Thickener is mixed to prepare negative electrode slurry.

[0163] The negative electrode slurry was uniformly coated on a copper foil with a thickness of 15 μm, then dried and pressed to produce a density of 1.684 g / ...

experiment example 1

[0168] Experimental example 1: Evaluation of life at 45°C (evaluation of capacity retention rate after 600 charge-discharge cycles)

[0169] For the lithium secondary batteries of Examples and Comparative Examples, charge (CC / CV 1C 4.2V 0.1C cut-off (CUT-OFF)) and discharge (CC 1C 2.7V cut-off) were repeated 600 times at 45°C.

[0170] The capacity retention rate after 600 charge-discharge cycles was calculated as a percentage by dividing the discharge capacity at the 600th charge-discharge cycle by the discharge capacity at the first cycle (initial capacity).

[0171] Capacity retention rate (%) = (600th discharge capacity / 1st discharge capacity) × 100

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com