Dish washing machine inner container flanging equipment

A dishwasher liner and flanging technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of rough flanging surface, secondary processing, cumbersome operation, etc., and improve the quality of flanging and efficiency, guaranteed accuracy, and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

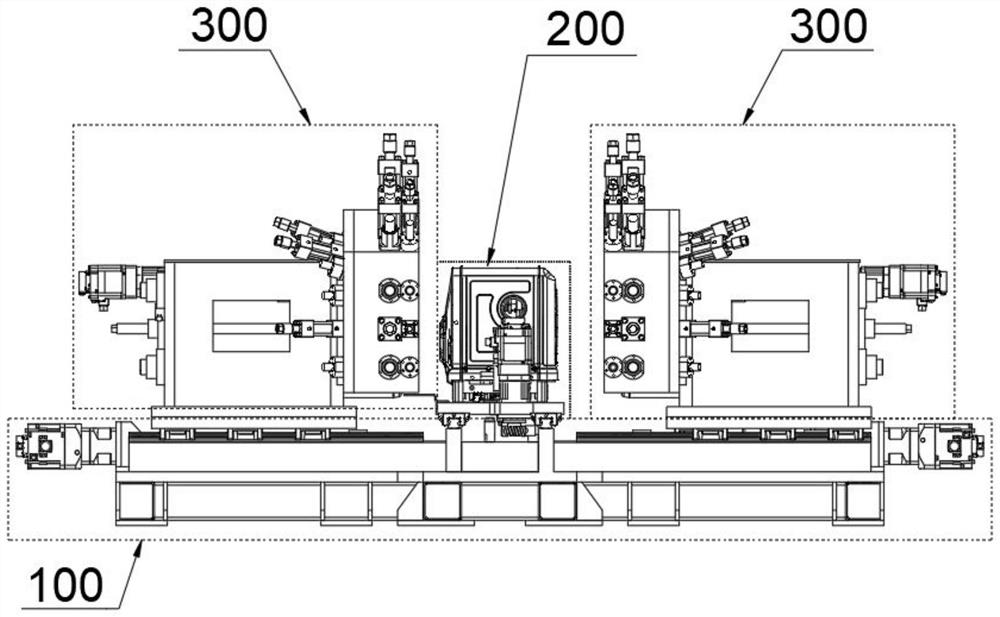

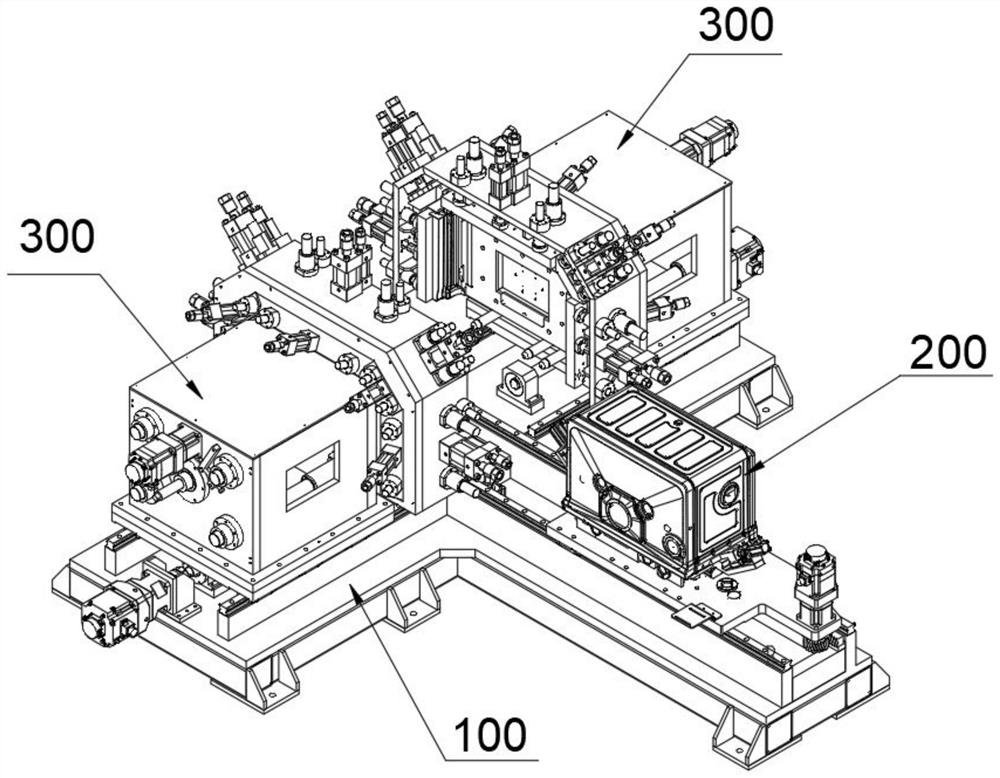

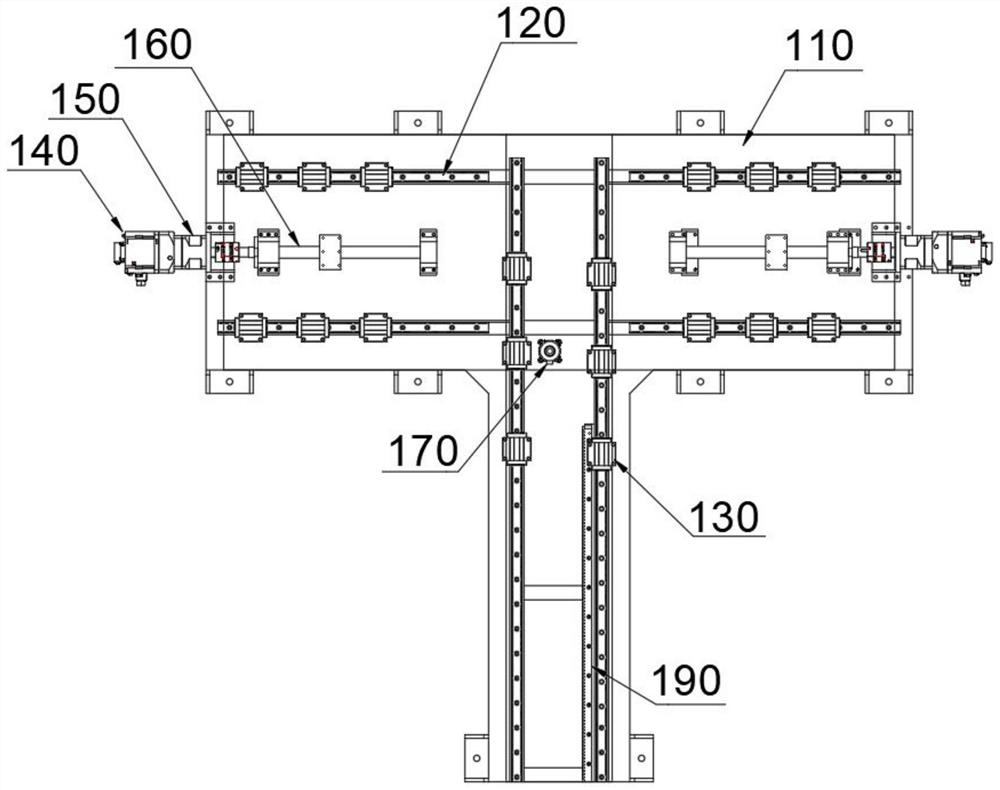

[0064] combine Figure 1-14 As shown, a dishwasher liner flanging device provided by the present invention includes: a base servo drive mechanism 100, a feeding mechanism 200 and a flanging mechanism 300. The base servo drive mechanism 100 includes a welding base 110, which is vertically and horizontally arranged on the welding base A plurality of guide rails 120 for guiding on 110, a slider 130 clamped on the guide rail 120, a servo motor 140 symmetrically installed on the welding base 110 for driving, a planetary reducer 150 connected to the servo motor 140 , the screw assembly 160 installed on the welding base 110 and connected to the planetary reducer 150, the lower positioning cylinder 170 installed in the middle of the welding base 110, the lower positioning guide post 180 connected to the driving end of the lower positioning cylinder 170 and the guide rail 120 The inner rack 190 can realize the positioning and movement of the feeding mechanism 200 and the flanging mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com