High-strength two-axle swing arm forging process

A high-strength, high-tech technology, applied in the field of forging technology, can solve the problems of shortened service life, lack of material on the surface of the bend, and failure to meet customer needs, etc., to achieve the effect of sufficient service life and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

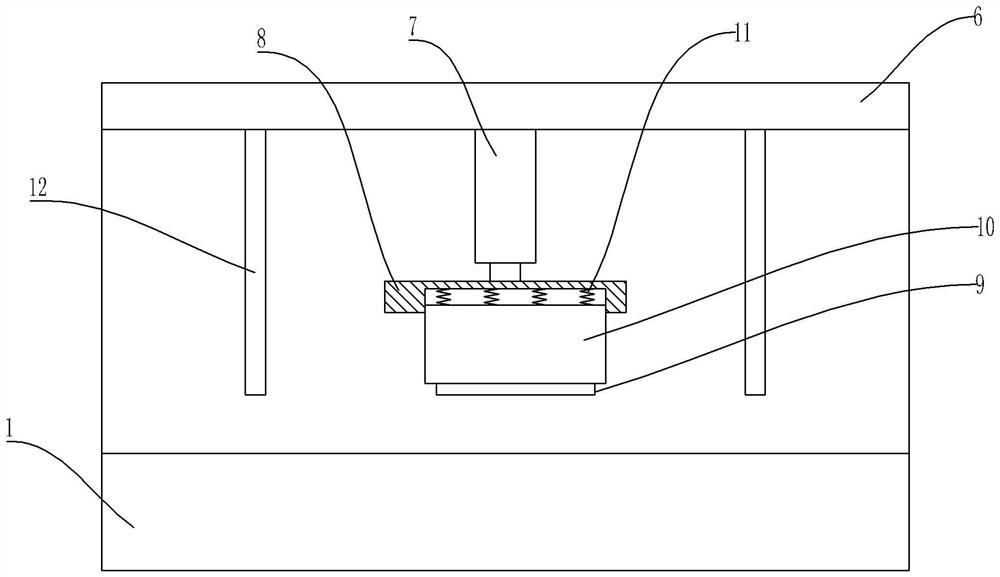

[0027] Example

[0028] The high-strength two-bridge swing arm forging process includes the following steps:

[0029] S1 blanking; take the steel of the required size;

[0030] S2 is heated for the first time; the steel is heated to 1150±50℃; the heating time is 1-1.5h, and the holding time is 1.5-2h;

[0031] S3 pull out the bar; carry out the elongation operation on the heated billet, and flatten the top of the billet after the pull-out treatment.

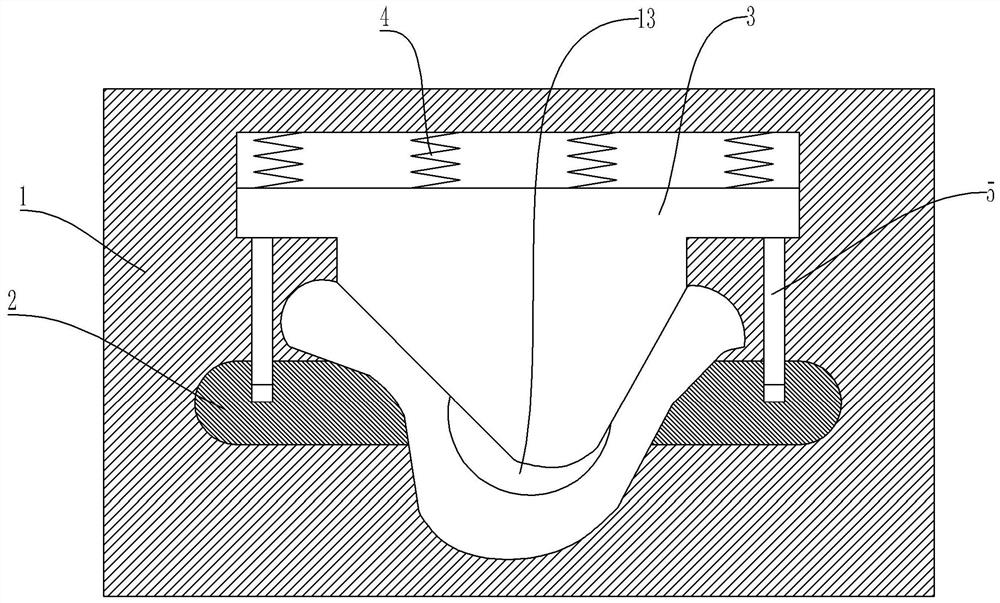

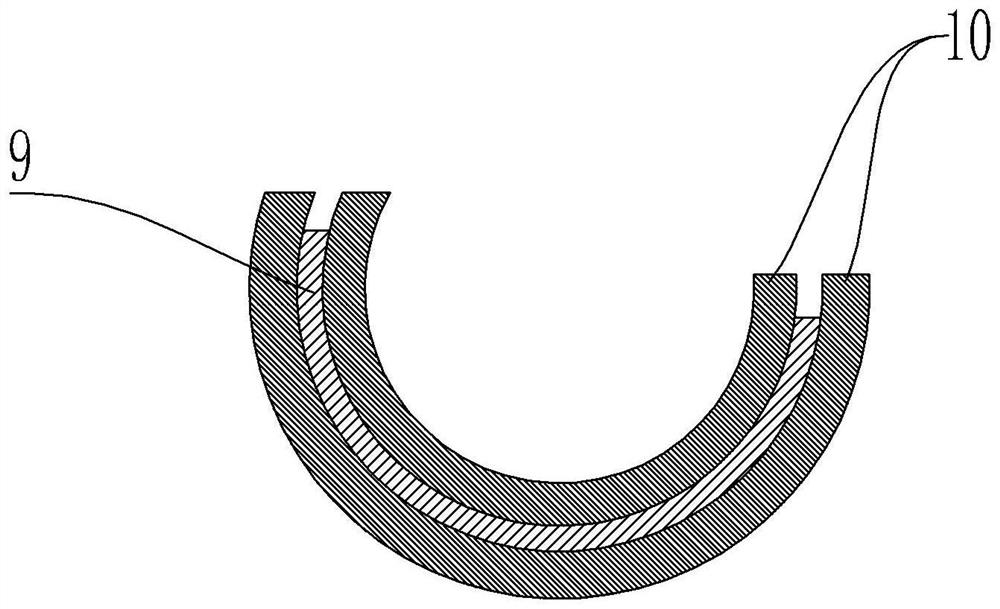

[0032] S4 bending; bending the billet to increase the rounded corners of the billet, allowing more material to be reserved at the billet’s curved shape, thereby increasing the thickness of the billet’s curved shape; The folding problem all occurs in the material-increasing part at the bend of the blank, that is, the excess part 13 that allows the folding to appear on the surface of the bend of the blank;

[0033] S5 cutting; use cutting equipment to cut the billet after the bending process, so that the excess part 13 of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com