High-performance foam cutting machine

A high-performance, cotton machine technology, used in metal processing, coating, devices for coating liquids on surfaces, etc., can solve the problems of insufficient cutting accuracy, low machine production efficiency, low cutting efficiency, etc., to improve cutting efficiency and Accuracy, optimize the spray method, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with accompanying drawing:

[0021] In order to make the purpose, features and advantages of the present invention more obvious and easy to understand, the practical

[0022] The novel specific implementation mode is described in detail. Several embodiments of the invention are shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

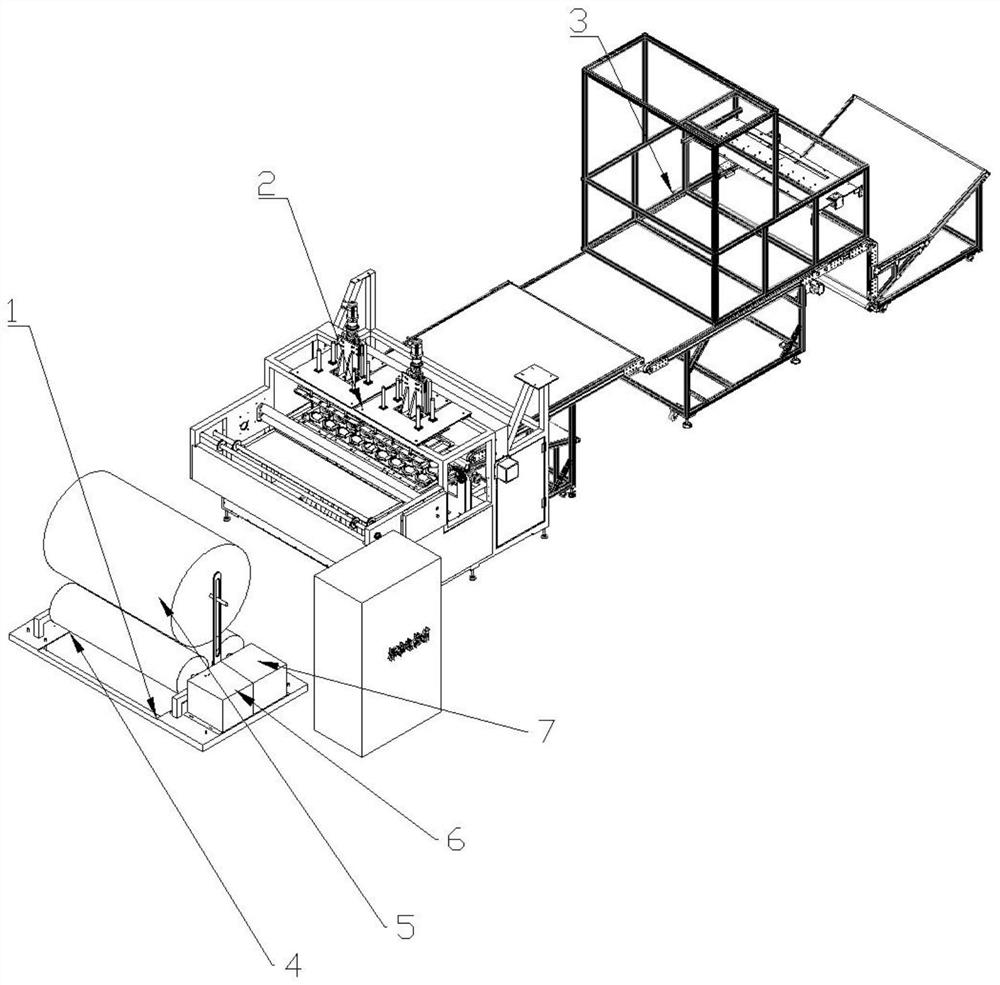

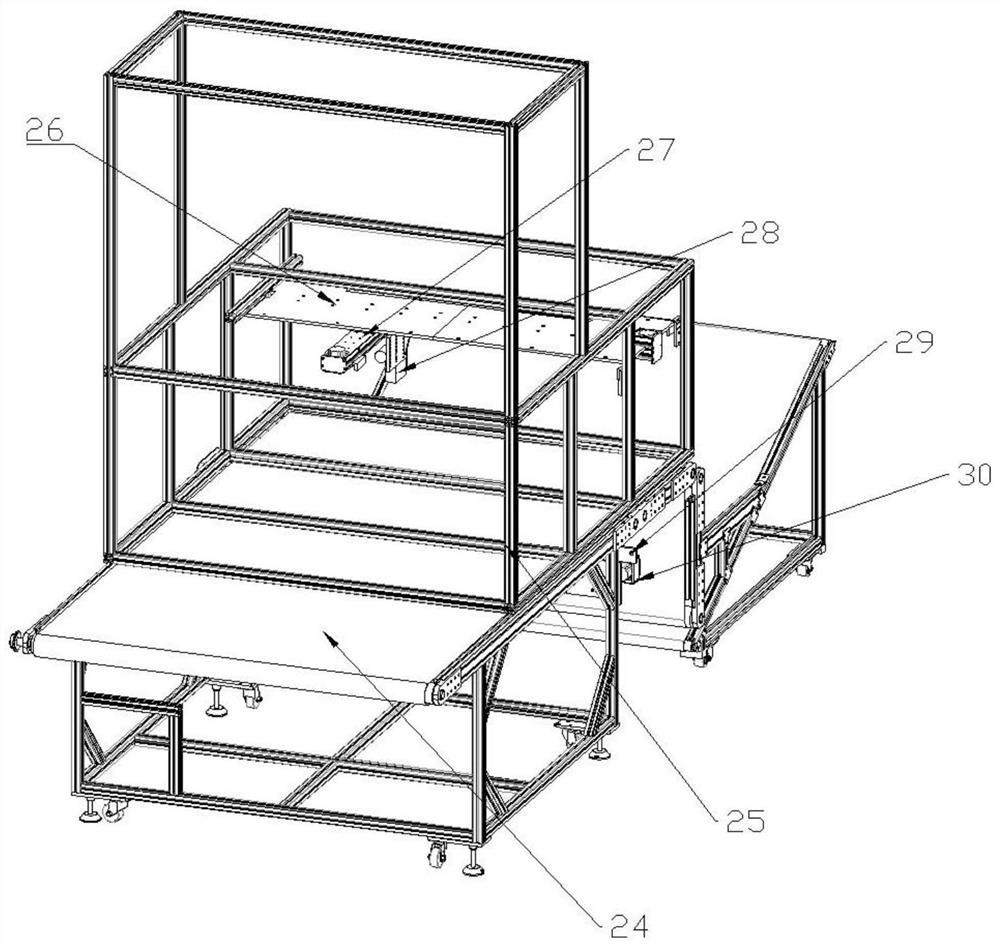

[0023] Such as figure 1 A high-performance foam cutting machine is shown, including a feeding part 1, a cutting part 2 and a glue spraying line part 3.

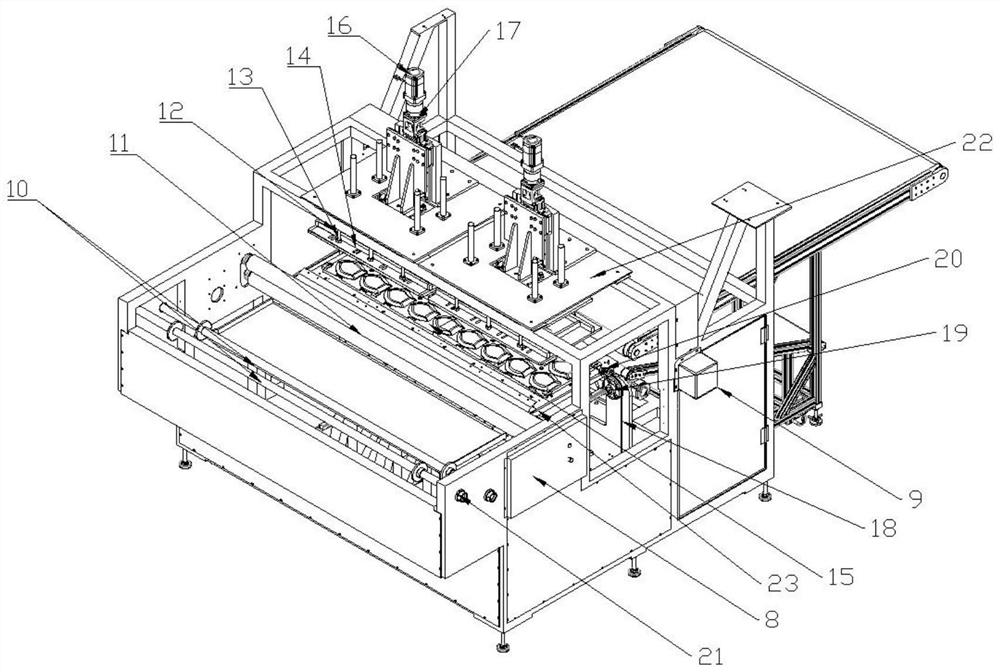

[0024] to combine figure 2 As shown, the feeding part 1 includes a feeding motor 6, a feeding motor 8, a receiving motor 9, an offset motor 7, a friction roller 4, an offset sensor 21, a tension shaft 10 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap