PCB slice and preparation method thereof

A technology of slicing and prepreg, which is used in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit components and other directions, which can solve the problem of copper tearing in hole wall pits, slow down the drilling feed speed and retract speed, and increase frictional heat. and other problems, to achieve the effect of improving production efficiency, prolonging the life of the drill bit, and prolonging the life of the drill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

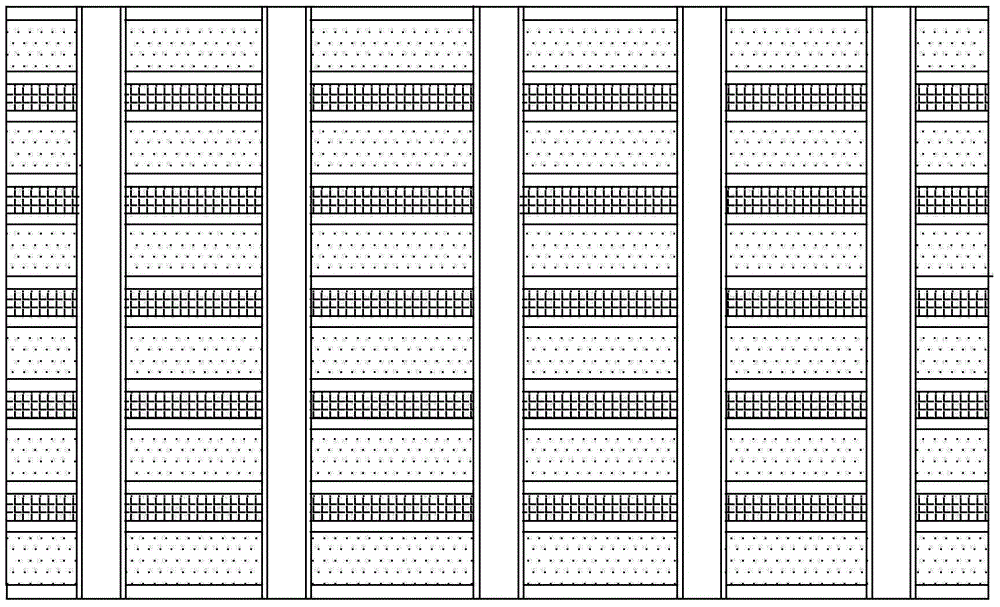

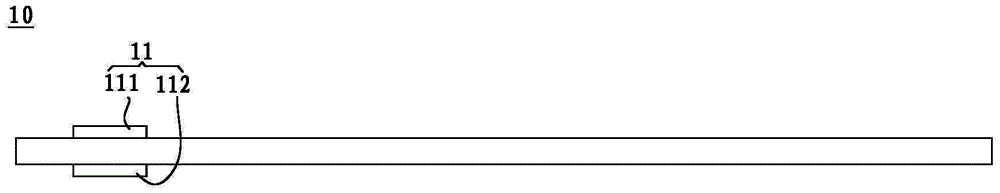

[0021] refer to Figure 2-5 , a PCB slice provided in this embodiment, including five inner layer sliced boards 10, two outer layer copper foils 30, and a prepreg 40 as an adhesive material. Each inner layer slicing board 10 is provided with a copper foil drilling position 11, and the copper foil drilling position 11 includes an upper copper foil 111 and a lower copper foil 112 attached to the upper and lower surfaces of the inner layer slicing board 10; The copper foil drilling positions 11 on one inner slice board 10 are staggered from the copper foil drilling positions 11 on the other inner slice boards 10 . The outer layer copper foil 30, the inner layer slice plate 10 and the prepreg 40 are sequentially pressed together, so that the two outer layer copper foils 30 are located at the outermost layer, and the five inner layer slice plates 10 are located between the two outer layer copper foils 30, and A prepreg 40 is arranged between the outer layer copper foil 30 and th...

Embodiment 2

[0028] A PCB slicing provided in this embodiment includes 6 inner-layer slicing boards, two outer-layer copper foils and a prepreg. Each inner layer slice board is provided with a copper foil drilling position, the copper foil drill hole position includes the upper copper foil and the lower copper foil on the lower surface of the inner layer slice board; each inner layer slice board The copper foil drilling positions on the board are staggered from the copper foil drilling positions on other inner slice boards. The outer layer copper foil, the inner layer slice board and the prepreg are pressed together sequentially, so that the two outer layer copper foils are located on the outermost layer, the six inner layer slice boards are located between the two outer layer copper foils, and the outer layer copper foil and the inner layer Prepregs are arranged between the layer slicing plates and between the two inner layer slicing plates, and a slicing hole with a cross-sectional area ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap