Hoisting device and hoisting method for full-section water stop curtain cloth

A hoisting device, full-section technology, applied in the directions of transportation, packaging, load hoisting components, etc., can solve the problems of improper installation and easy folding, and achieve the effect of avoiding rework, ensuring accurate installation, and preventing overturning and bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0061] Embodiment 2, its difference with embodiment 1 is, as Figure 15 and Figure 16 As shown, the K-shaped sleeve 3-2 is provided with a rotation auxiliary mechanism 16 for connecting the shoulder shaping assembly 2 so that the shoulder shaping assembly 2 can swing left and right; the rotation auxiliary mechanism 16 includes a rotation auxiliary housing 16-1 and the connecting sleeve 16-2 hingedly connected in the rotating auxiliary housing 16-1, the hinge shaft of the connecting sleeve 16-2 is set in the axial direction of the water stop curtain 13; the connecting sleeve 16-2 and the shoulder shaping assembly The sizing rods of 2 are connected so that the shoulder sizing assembly 2 can swing left and right in the plane of the water-stop curtain.

Embodiment 3

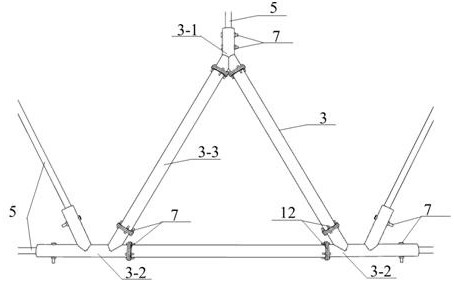

[0062] Embodiment 3, its difference with embodiment 1 is, as Figure 13 As shown, the connector 3 includes a Y-shaped sleeve 3-1 and two 1-shaped sleeves 3-4 symmetrically arranged on both sides of the Y-shaped sleeve 3-1, and the 1-shaped sleeve 3-4 and The Y-shaped sleeve 3-1 is connected by the fixing pipe 3-3 to form an isosceles triangle structure; and the shoulder shaping component 2 is omitted. This embodiment 1 is mainly used for water-stop cords with smaller specifications.

Embodiment 4

[0063] Embodiment 4, its difference with embodiment 1 is, as Figure 14 As shown, for heavier or larger water-tight curtains, two symmetrical shoulder shaping components can also be added, and correspondingly, a sleeve can be added to the K-type connecting sleeve 3-2 for passing through the shaping rod 5Connect the shoulder shaping components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com