Filling mechanism for cosmetic production

A cosmetic and filling technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of cosmetic deterioration and dripping, and achieve the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

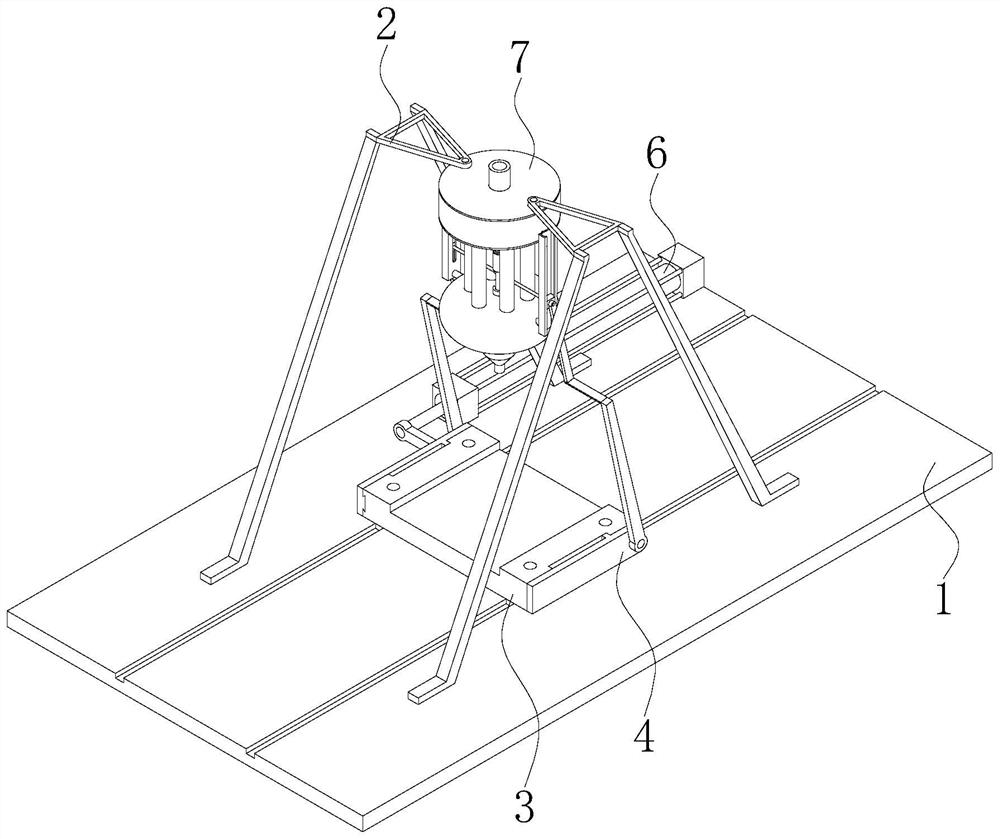

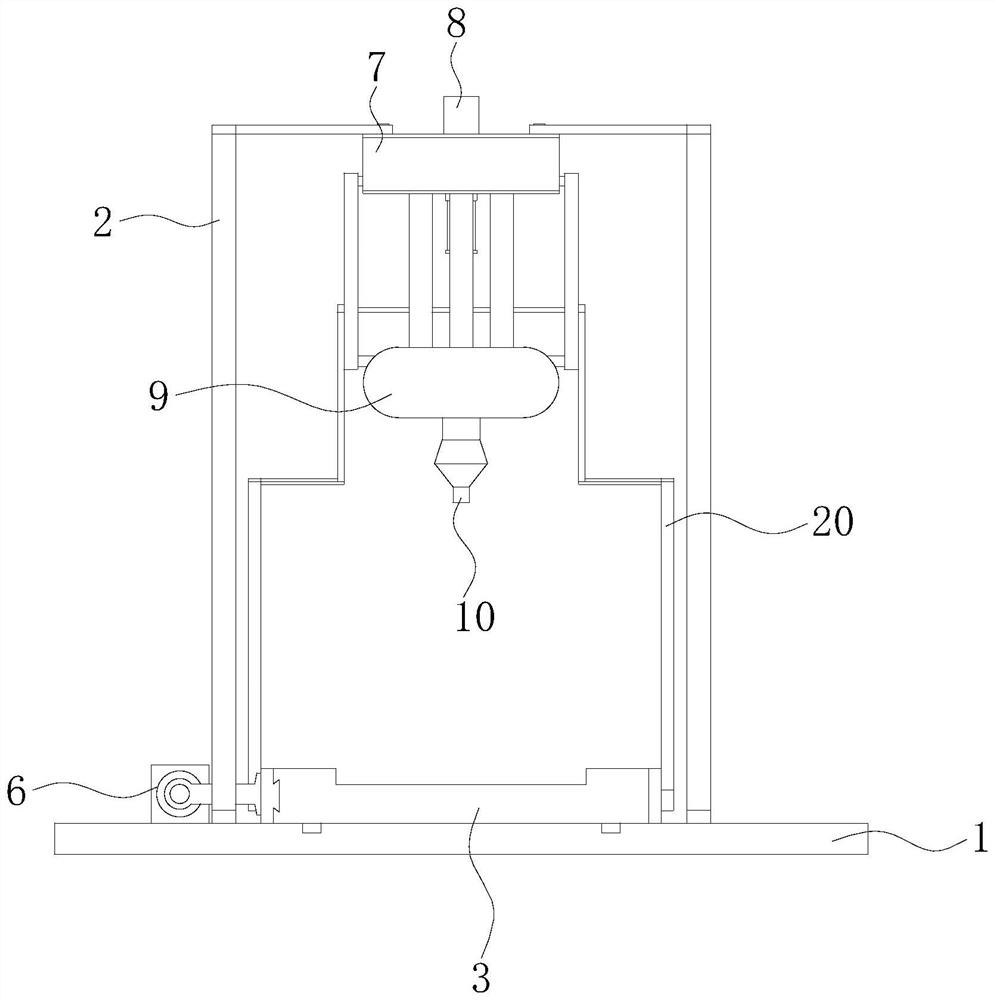

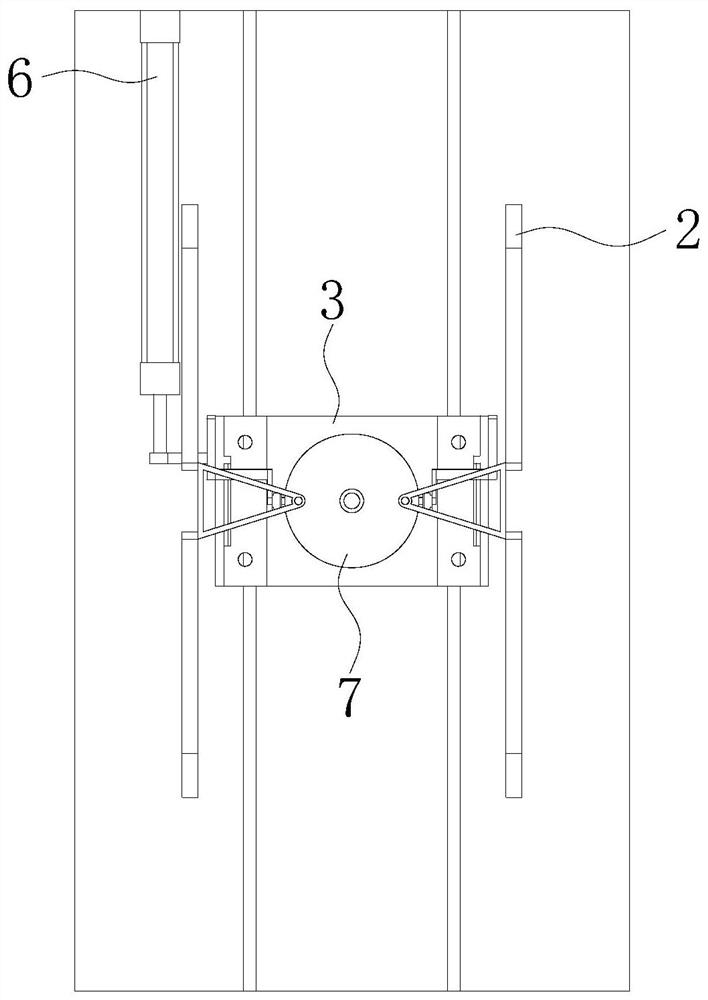

[0024] like Figure 1-7 As shown, a filling mechanism for cosmetics production includes a base plate 1 and two supports 2, and the two supports 2 are fixedly connected to the front and rear ends of the upper surface of the base plate 1 respectively. The upper surface of the base plate 1 is provided with a supporting plate 3, and There are threaded holes on the plate 3, which can be used to install the clamping device. The moving plate 4 is slidably installed on the front and rear sides of the supporting plate 3. The front and rear sides of the supporting plate 3 are provided with grooves 5. The inner wall of the moving plate 4 There are protrusions, and the protrusion structure is plugged into the groove 5, and the groove 5 is regularly coated with grease. The supporting plate 3 is slidably connected with the bottom plate 1. The bottom surface is fixedly equipped with a slide bar, the slide bar is slidably connected with the chute, grease is regularly applied in the chute, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap