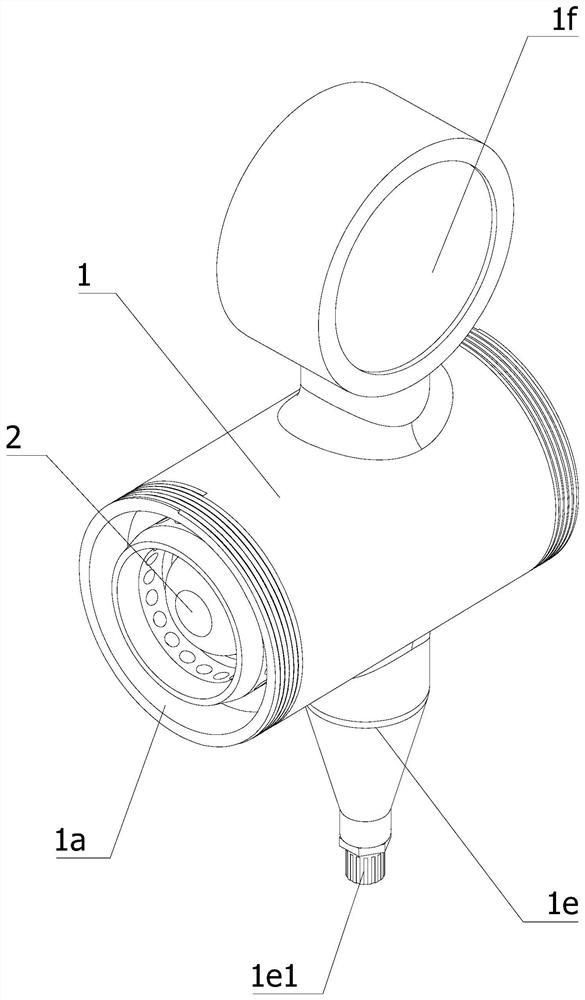

Connector structure for ventilation pipe of crankcase of wind driven generator

A crankcase ventilation and wind turbine technology, which is applied to wind turbines, wind energy power generation, pipes/pipe joints/pipes and other directions, can solve problems such as unfavorable wind turbine energy collection, unsatisfactory crankcase heat dissipation, and increased energy consumption, etc. Achieve the effect of solving poor heat dissipation, reducing energy consumption and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

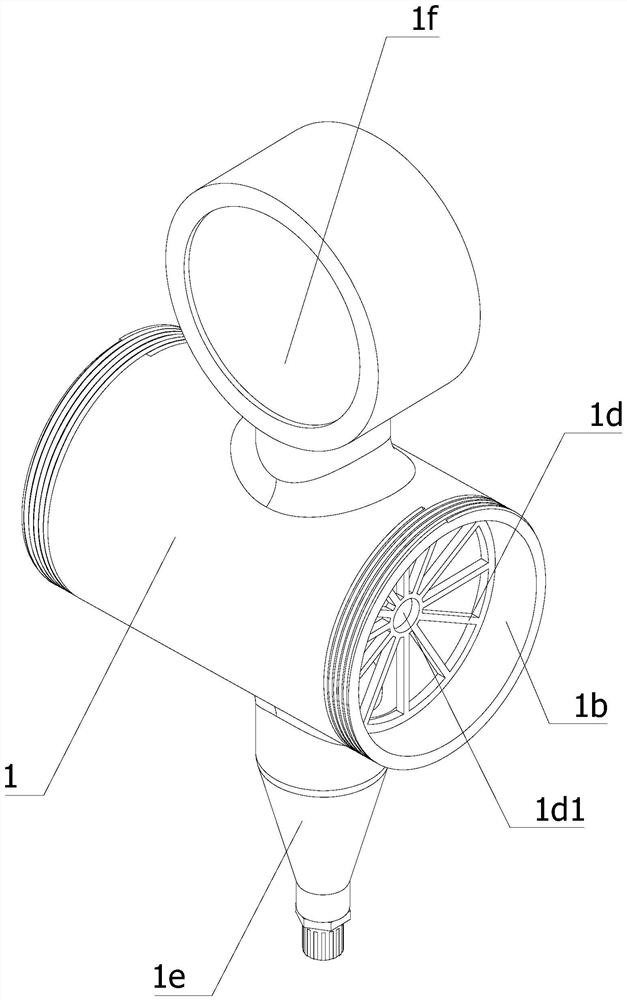

no. 1 example

[0045] In the first embodiment, when the slider 2 provided by the present application allows hot air to enter the joint body 1 through the first groove 2d, it is convenient to concentrate the hot air inside the first groove 2d, so that the hot air can be better pushed The slider 2 moves; the hot air is concentrated and discharged into the interior of the joint body 1 through several first air outlets 2d1 on the side wall of the connecting part 2a, so that the slider 2 can be displaced for a small distance to make the hot air Flowing into the joint body 1, when the pressure of the hot air in the crankcase is low, the hot air can also be discharged in time to facilitate the circulation of the hot air, reduce the heat in the crankcase, prolong the service life of the equipment, and solve the above problems.

[0046] Further, the slider 2 provided by the present application still has the defect of lack of stability when sliding, and at the same time, in the case of insufficient hot...

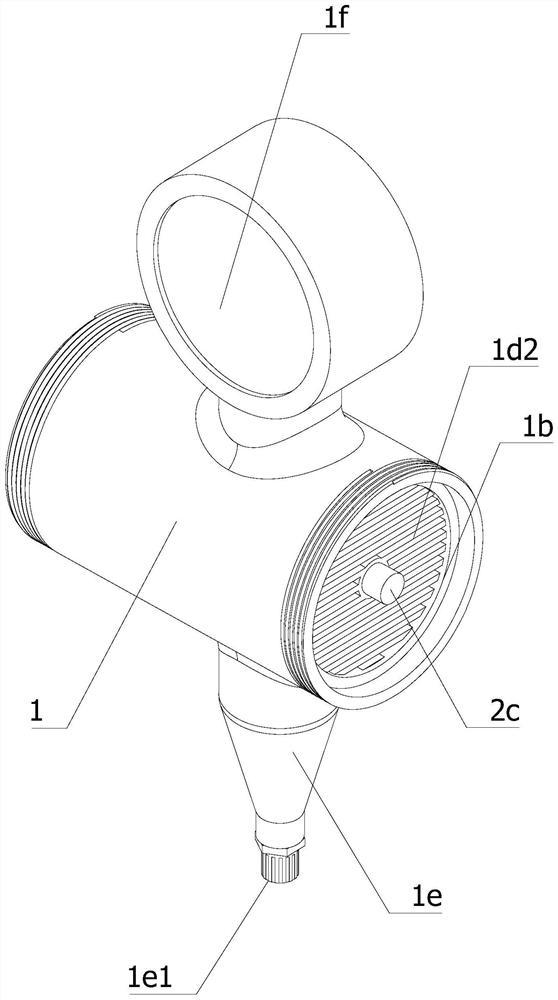

no. 2 example

[0048] In the second embodiment, the slider 2 provided by this application allows hot air to enter the joint body 1 through the second groove 2e, so that the hot air is concentrated in the second groove 2e, so that the hot air can better push the slider. Block 2 moves; the hot air is discharged into between the inner wall of the joint body 1 and the outer wall of the connecting portion 2a through several second air outlets 2e1 on the side wall of the connecting portion 2a, and then passes through the third air outlet 2e2 of the limiting portion 2b. The hot air is discharged into the interior of the joint body 1. Since the diameter of the outer wall of the stopper 2b matches the diameter of the inner wall of the joint body 1, the slider 2 moves in close contact with the inner wall of the joint body 1, and is prevented by the third air outlet 2e2. It solves the problem that the hot air cannot circulate due to the joint between the slider 2 and the inner wall of the joint body 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com