Method for monitoring safety state of pier-beam bearing connection part

A technology of safety status and connection parts, applied in the field of safety status monitoring of pier-beam support connection parts, can solve the problems of inability to timely predict the displacement status of the connection parts of the main girder and pier support, high cost of single pier-beam support connection state monitoring, Complicated problems such as relative linear displacement and angular displacement can achieve the effect of improving safety early warning ability, low cost and low requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

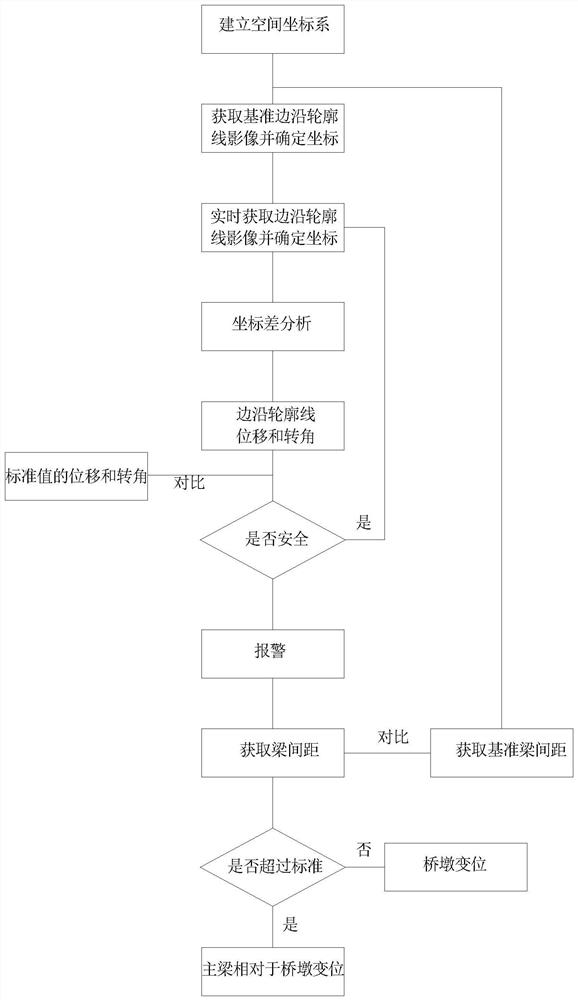

[0042] The method for monitoring the safety state of the pier-beam support connection part of the present invention comprises the following steps:

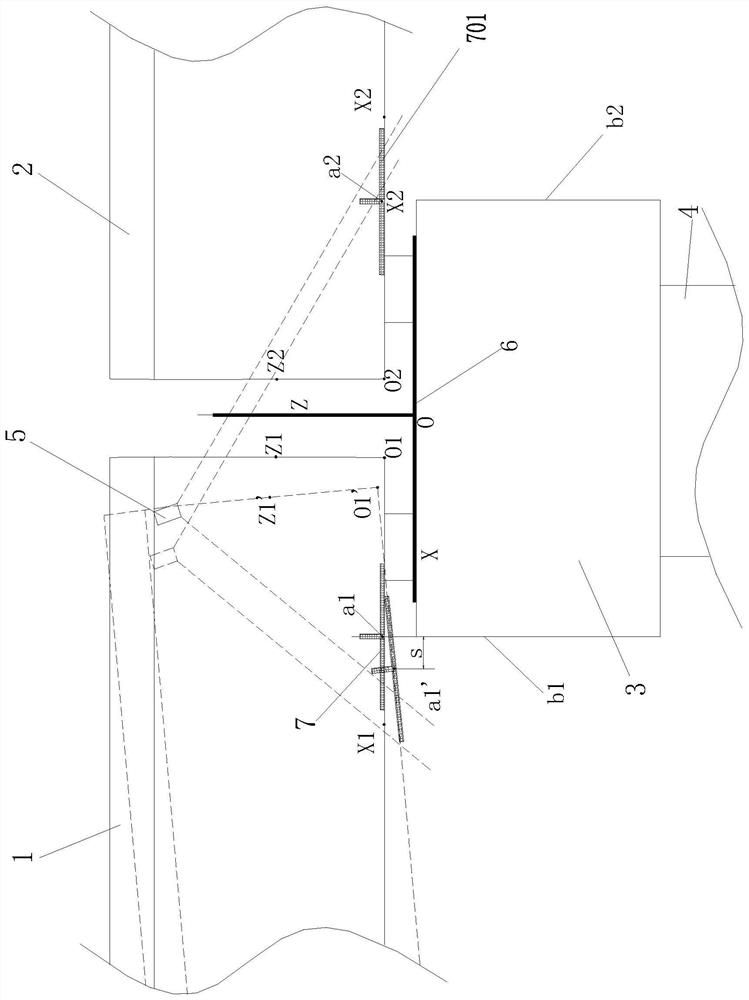

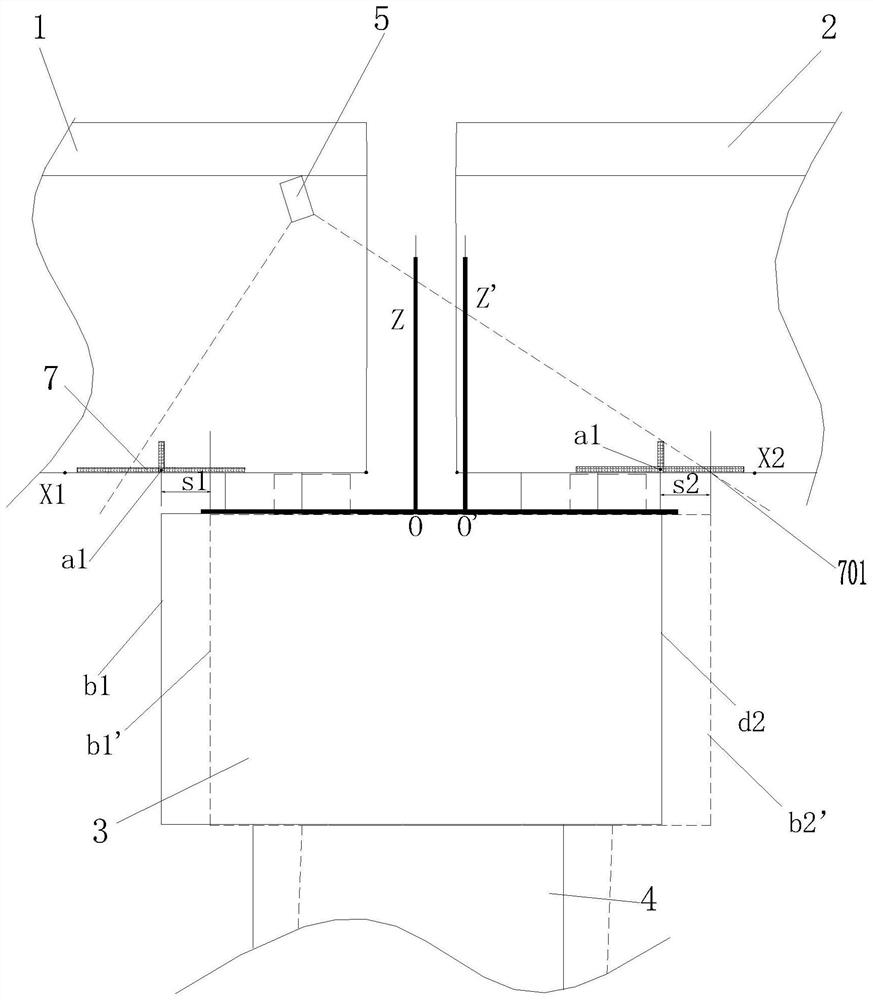

[0043] a. Establish a spatial coordinate system, the origin of which is located near the supporting connection between the main girder and the bridge pier;

[0044] b. Obtain the main girder 1 by taking a camera (two main girders are supported and connected on one pier, as shown in the figure, main girder 1 and main girder 2, in the embodiment of the present invention, the displacement of the main girder is mainly based on the main girder 1 For example) the edge contour line of the web, and determine the coordinates of the edge contour in the space coordinate system; the camera's field of view (the range where the dotted line corresponding to the camera 5 in the figure) position should be able to photograph the web The edge contour line, which includes the edge contour line at the end and the edge contour line at the bottom, can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com