Novel concrete construction vibration parameter rapid measuring device and method

A technology for rapid measurement and concrete application in measuring devices, processing of building materials, construction, etc. It can solve problems such as surface appearance quality of vibrator traces, segregation of concrete mixture, complex and changeable performance, etc., to achieve optimal pouring and Effect of vibrating process, reducing urban noise, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

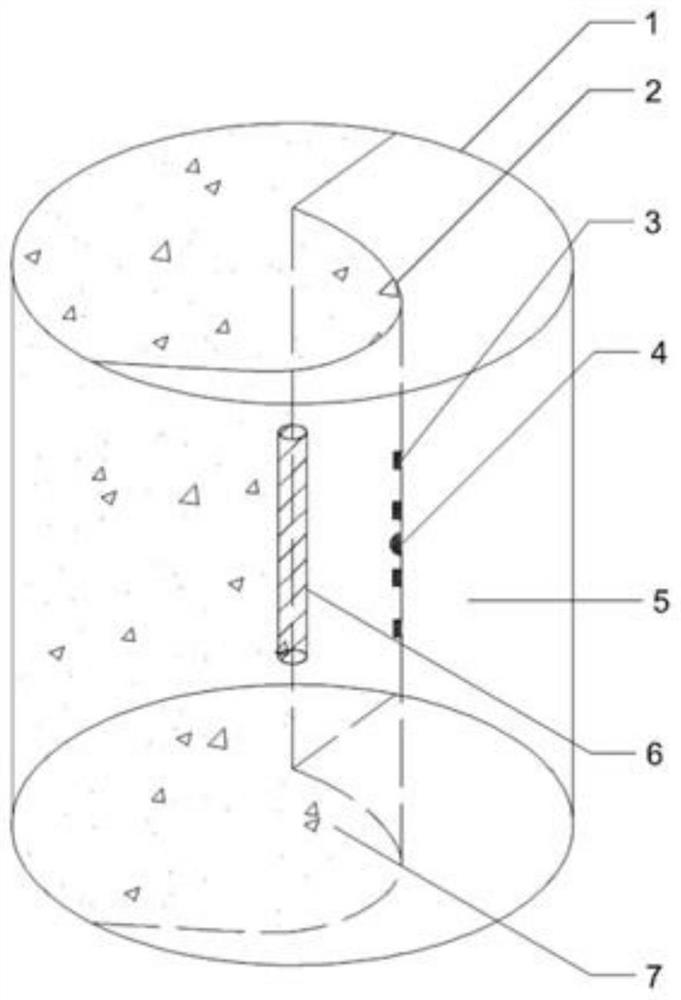

[0066] A new type of rapid measuring device for concrete construction vibration parameters, such as Figure 1-3 As shown, including a closed container 1 without a cover, a vibrator 6 and a data acquisition and analysis system;

[0067] A baffle 2 is arranged in the airtight container 1, and the baffle 2 is welded with the airtight container 1. The baffle 1 divides the inner space of the airtight container into two parts, namely the empty chamber A5 and the empty chamber B 7, and the empty chamber B 7 is filled with concrete. The tamping rod 6 is located in the middle of the airtight container and in the empty bin B 7, and is used for vibrating concrete;

[0068] The data acquisition and analysis system includes interconnected data processing centers and acquisition sensors. The main body of the acquisition sensor is placed in the empty warehouse A5 and its sensing end is in contact with the concrete. The internal concrete is in direct contact, and the main body is placed in t...

Embodiment 2

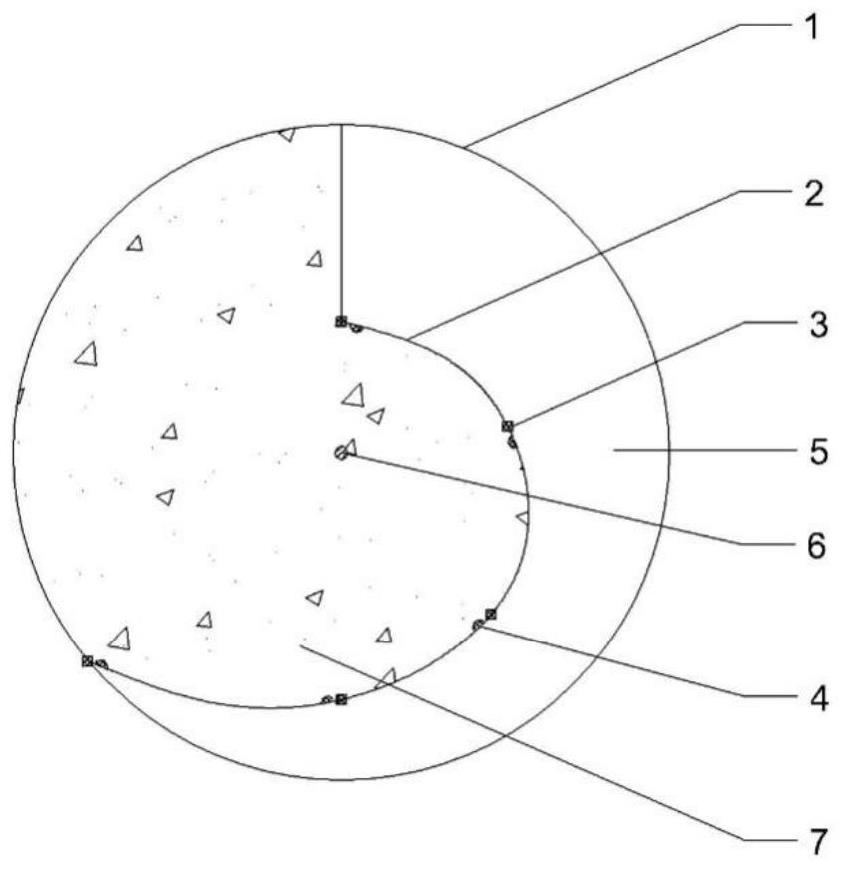

[0070] A new type of rapid measuring device for vibration parameters of concrete construction, as described in Example 1, the difference is that the baffle 2 is composed of a rectangular baffle and a spiral baffle, and one side of the rectangular baffle and the spiral baffle connected, the height of the baffle plate 2 is the same as that of the airtight container 1, and the baffle plate 2 is vertically fixed in the airtight container;

[0071] The side facing away from the spiral baffle forms an empty chamber A, and the side facing the spiral baffle forms an empty chamber B, and the volume of the empty chamber B 7 is larger than that of the empty chamber A 5 .

Embodiment 3

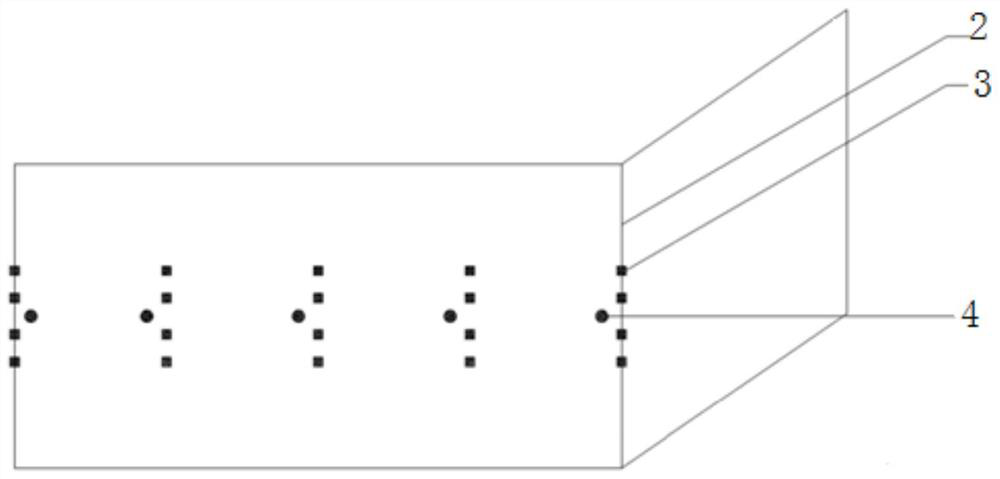

[0073] A new device for quickly measuring vibration parameters in concrete construction, as described in Example 2, the difference is that the acquisition sensor includes an energy acquisition sensor 4 and a lateral pressure acquisition sensor 3, and the energy acquisition sensor 4 is arranged at the height of the spiral baffle In the middle position, and a plurality of them are arranged in the same horizontal plane, the distances between the multiple energy harvesting sensors and the center of the vibrator 6 increase sequentially, and the increment Δ is the same;

[0074] One side of each energy harvesting sensor is provided with a group of lateral pressure collecting sensors, and each group of lateral pressure collecting sensors includes a plurality of lateral pressure collecting sensors, which are evenly distributed along the height direction of the spiral baffle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com