Full-automatic packaging equipment for RFID tags

A technology for RFID tags and packaging equipment, applied in the field of RFID tags, can solve the problems that the surface of the RFID tag cannot be kept flat, the edge of the protection strip is bent, and the edge of the RFID tag cannot be closely attached.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

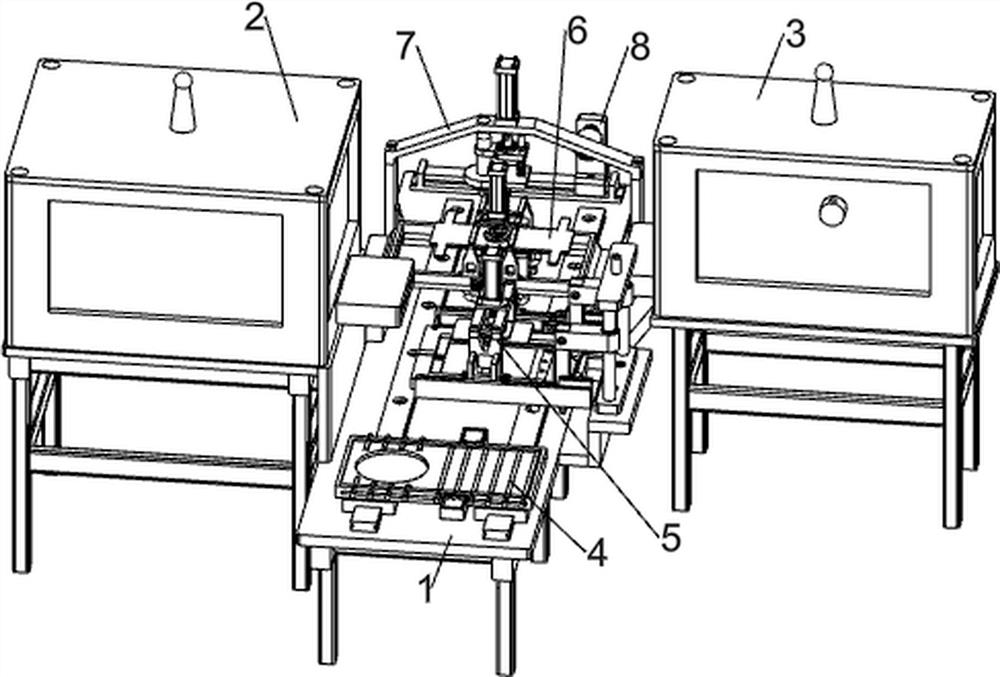

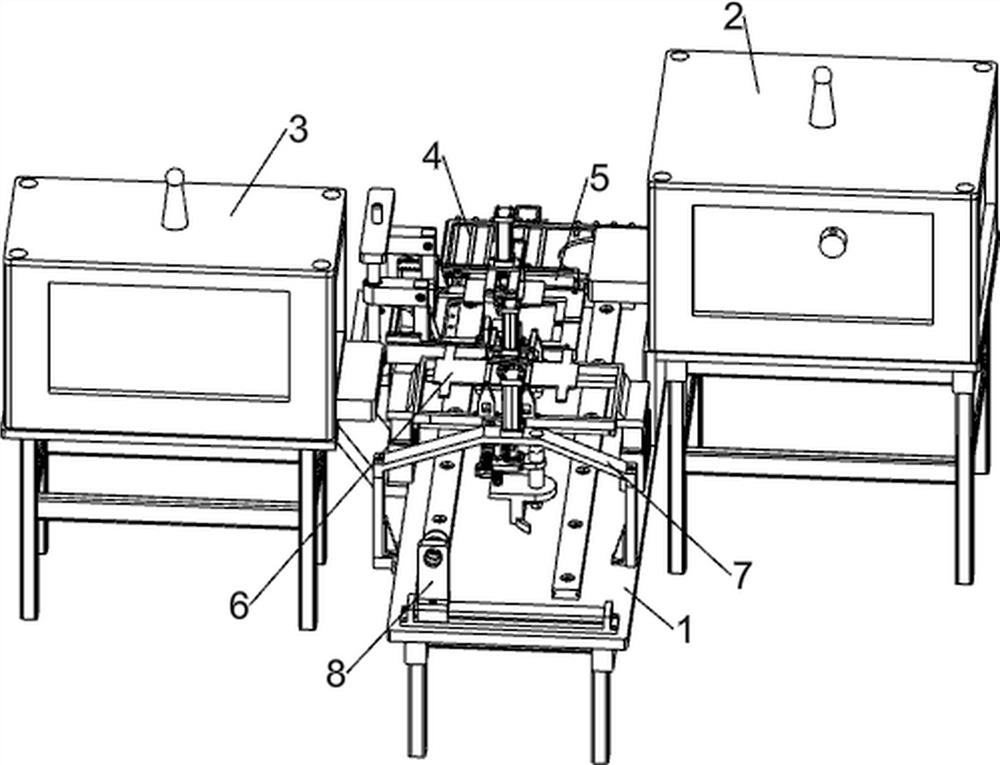

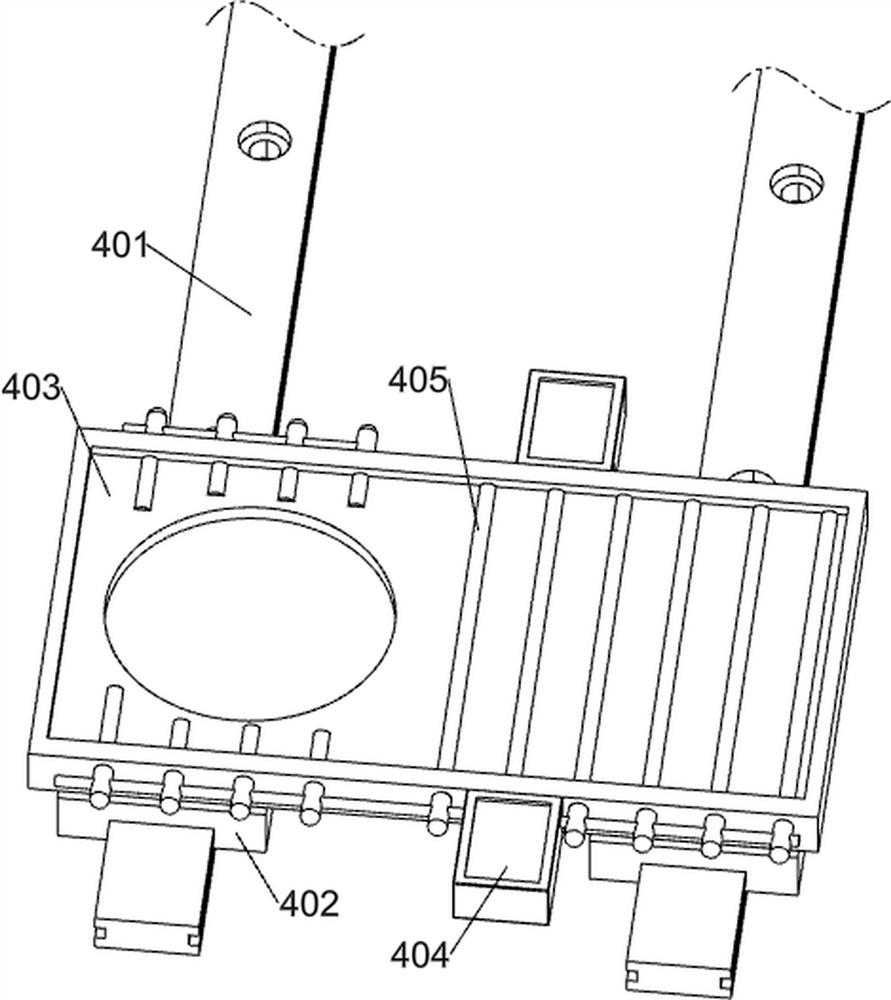

[0036] A kind of automatic packaging equipment for RFID tags, such as Figure 1-10 As shown, it includes a working machine plate 1, an antenna discharge machine 2, a protection strip discharge machine 3, a packaging transfer system 4, an antenna installation system 5, a protection strip packaging system 6, a glue dispensing connection system 7 and a drying system 8; Antenna discharger 2 is installed in the middle of the left side of the working machine board 1; a protective strip discharger 3 is installed in the middle and rear of the right side of the working machine board 1; a package transfer system 4 is installed on the top of the working machine board 1; An antenna installation system 5 is installed in the middle of the side; a protective strip encapsulation system 6 is installed on the rear middle side of the top of the working machine board 1 ;

[0037] When using the equipment, first add enough antennas and protective strips inside the antenna discharger 2 and the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com