Intelligent dosing system for sludge in-situ treatment

A technology of in-situ treatment and dosing system, applied in the field of chemical dosing system and mud treatment device, can solve the problems of environmental protection, environmental pollution, safety threats, etc., and achieve the effect of ensuring uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

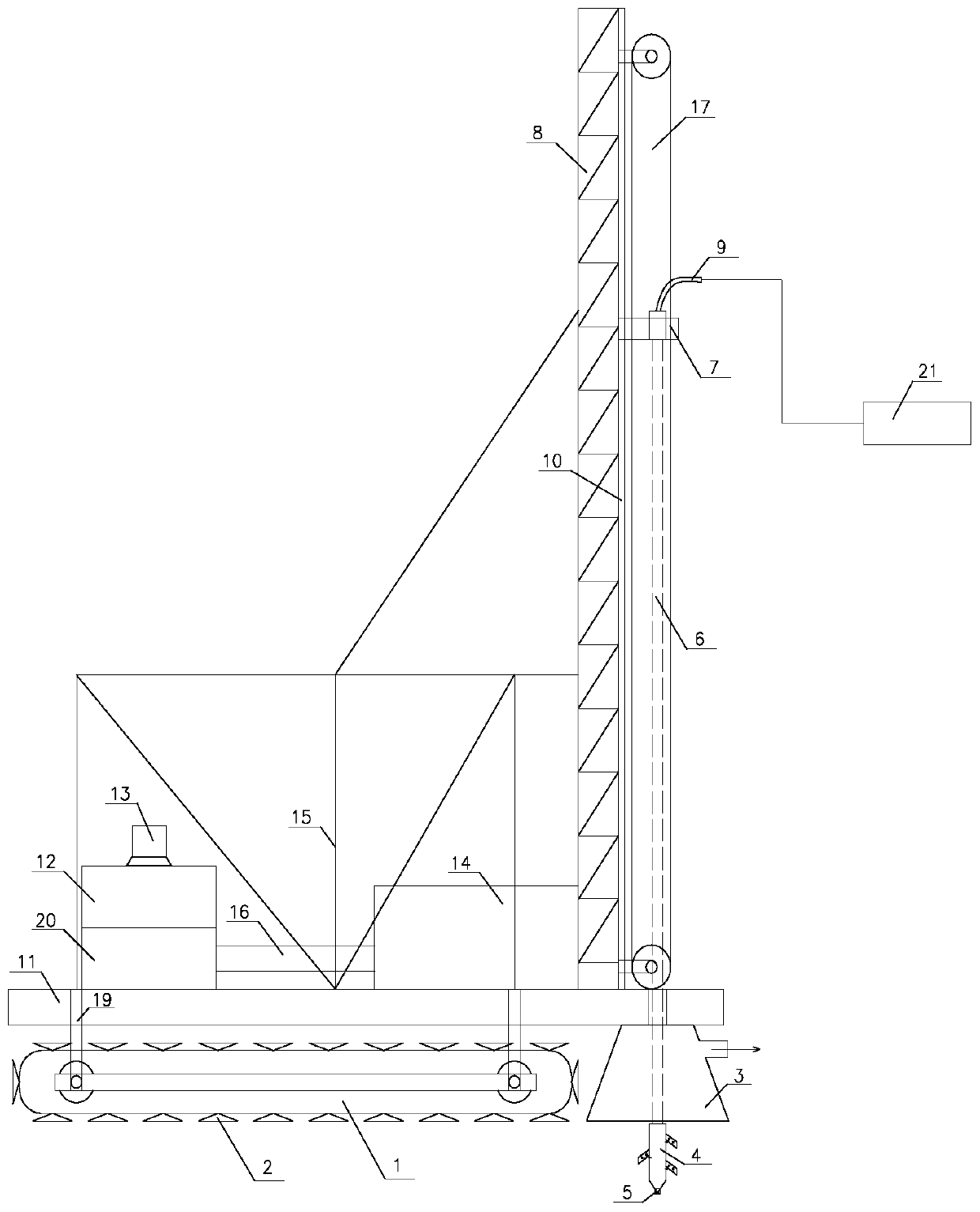

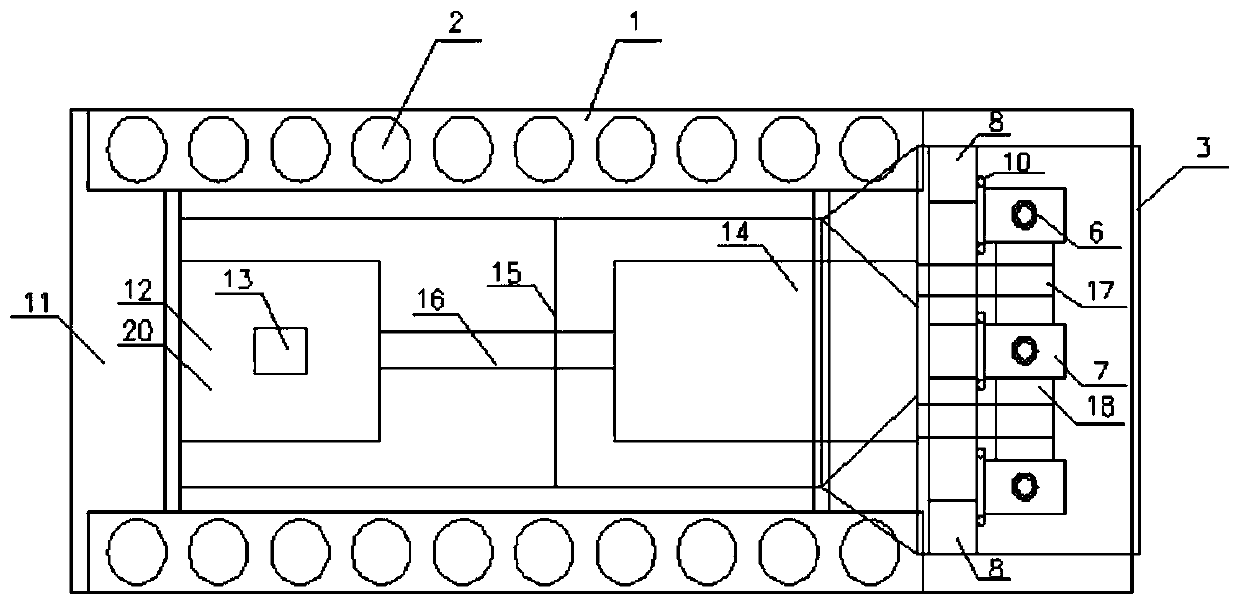

[0029] In this example, see Figure 1-Figure 3, an intelligent dosing system for sludge in-situ treatment, which also includes a main frame 11, including a walking subsystem, a positioning subsystem, a stirring subsystem, and a dosing subsystem; the walking subsystem includes a main frame 11, a suspension 19, Rubber crawler 1, polyurethane suction cup 2 and travel control system 12, rubber crawler 1 and main frame 11 are connected by suspension 19, and a series of polyurethane suction cups 2 are arranged on the rubber surface of rubber crawler 1 facing away from the track wheel, when walking When the subsystem is walking or the stirring subsystem is in the drilling process, the polyurethane suction cup 2 is tightly sucked to the sludge covering film, or the polyurethane suction cup is tightly sucked to the construction cushion, so that the polyurethane suction cup forms a temporary anti-slip and positioning device; Walking control system 12 is installed on main frame 11, and w...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, especially in that:

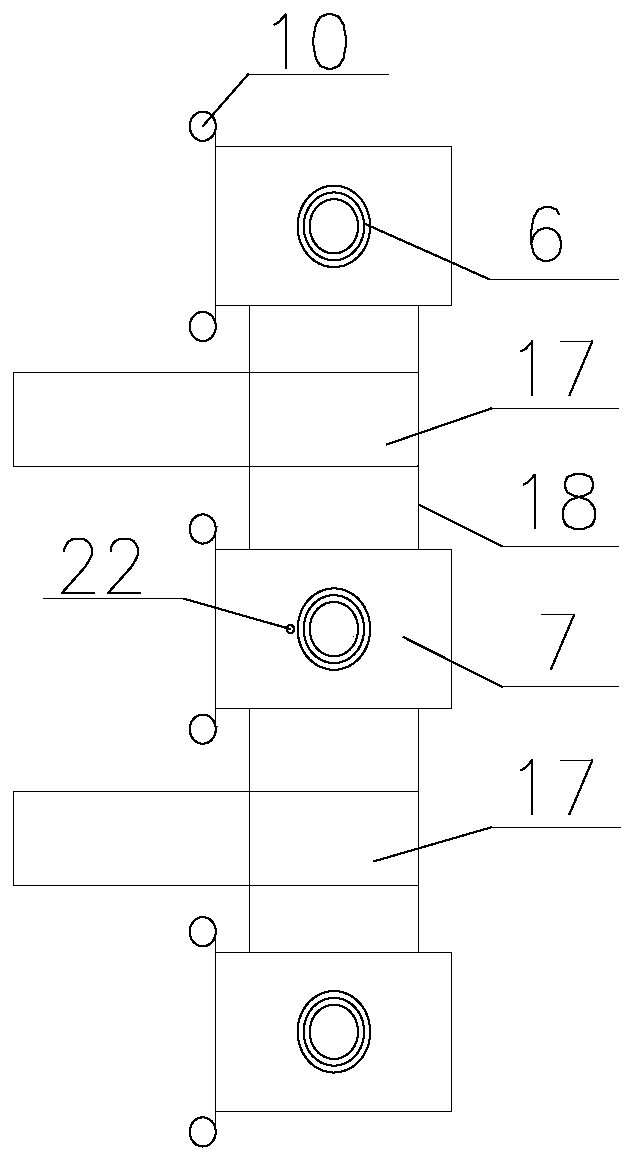

[0042] In this embodiment, the intelligent control system controls the dosing subsystem to add at most three different medicines, and by controlling the medicine injection pump 21, the interval and duration of adding different medicines are regulated. The drill pipe 6 and the triple drug injection pipe 9 can consider the interaction between the chemical reactions of the agents, and inject different types of agents according to the sequence of the chemical reactions. Up to three different agents can be added. These agents react quickly in the sludge and Destroy the microstructure of the sludge. If you need to add two or one agent, you don’t need to replace the drill pipe. You can directly use the inner layer and the middle layer to realize the injection of two agents, and only use the inner layer pipe to realize the injection of a single agent.

[0043] In this embodiment, the injection agent gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com