Apparatus and method for measuring thickness of unit cell

A unit cell and measuring unit technology, which is applied to measuring devices, battery pack components, secondary battery testing, etc., can solve problems such as difficulty in applying measurement methods and only selection of inspection methods, achieve highly accurate thickness and reduce failures rate, the effect of highly accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

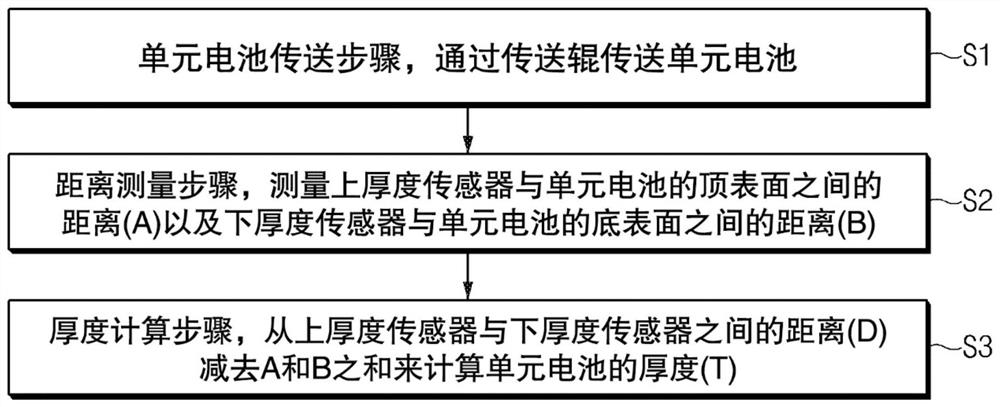

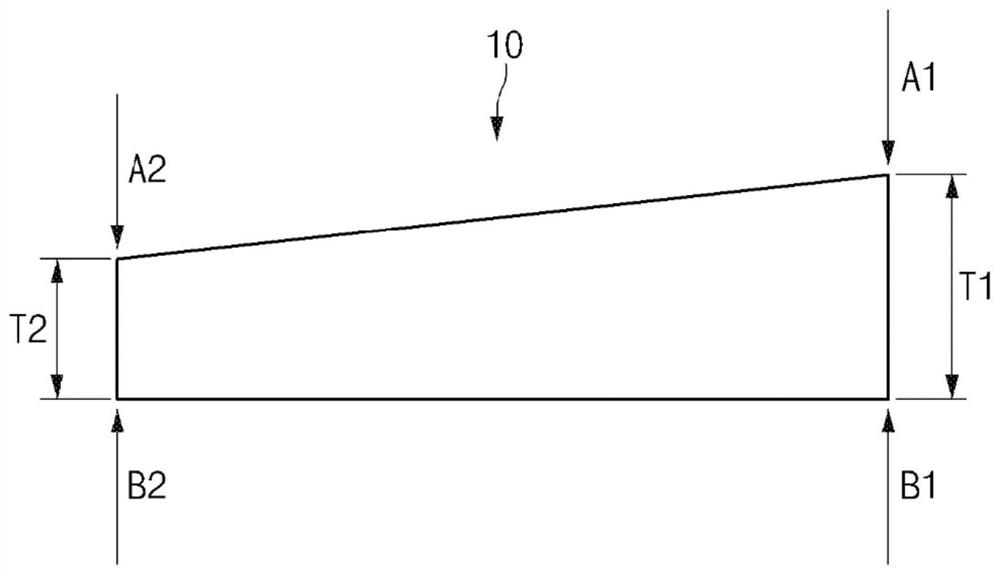

[0039] In the present invention, as a first embodiment, a method for measuring the thickness of the unit cell 10 is provided. Such as figure 1 , which shows the sequence of the method for measuring the thickness according to the first embodiment of the present invention, the measuring method of the present invention is characterized in that the thickness from the fixed position to the unit cell 10 is measured during the transfer of the unit cell 10 The thickness of the unit cell 10 is measured by changing the distance.

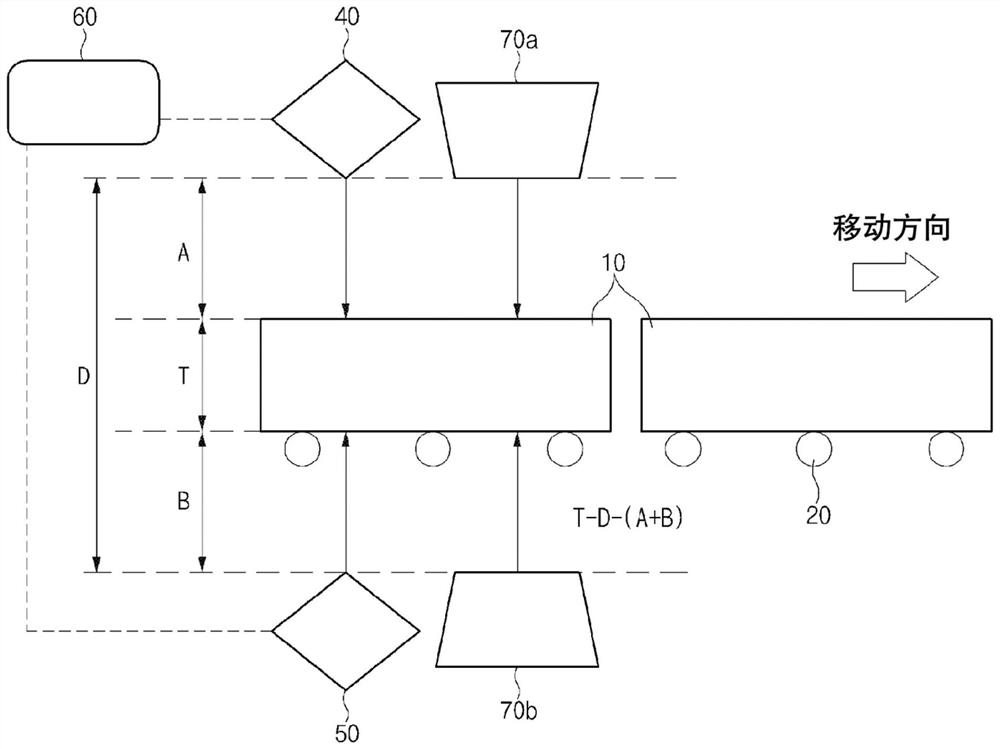

[0040] refer to figure 2 , which schematically shows the thickness measuring device of the present invention, describes the thickness measurement of the unit cell 10 of the present invention. When the unit cells 10 are transported by the transport rollers 20 arranged side by side at a predetermined distance from each other, light is irradiated from the upper side and the lower side of each unit cell 10 to the upper and lower surfaces of the unit cells 10, a...

no. 2 approach

[0055] Furthermore, in the present invention, as a second embodiment, there is provided a thickness measuring device for the unit cell 10 that can measure the thickness of the unit cell 10 by the measuring method according to the first embodiment.

[0056] In this embodiment, the thickness measuring device includes: a plurality of conveying rollers 20 which sequentially convey the unit cells 10 and are spaced apart from each other by a predetermined distance; The moving path of 10 irradiates light and counts the time when reflected light is received, thereby measuring the thickness of each unit cell 10 .

[0057] The thickness sensor includes an upper thickness sensor 40 disposed above the conveying rollers 20 to irradiate light onto the top surfaces of the unit cells 10 passing between the conveying rollers 20, and count the time when the reflected light is received, thereby measuring the distance from the unit cell 10; and a lower thickness sensor 50 disposed below the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com