Laser system with pulse duration switch

A technology of lasers and optical switches, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of slow tunability and large tunability of movable gratings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

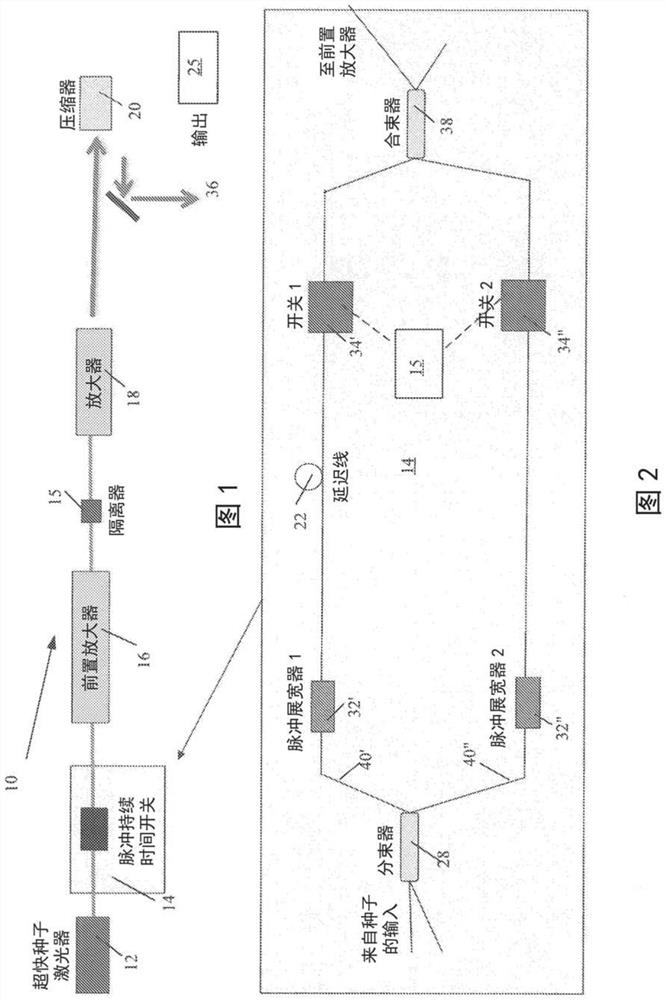

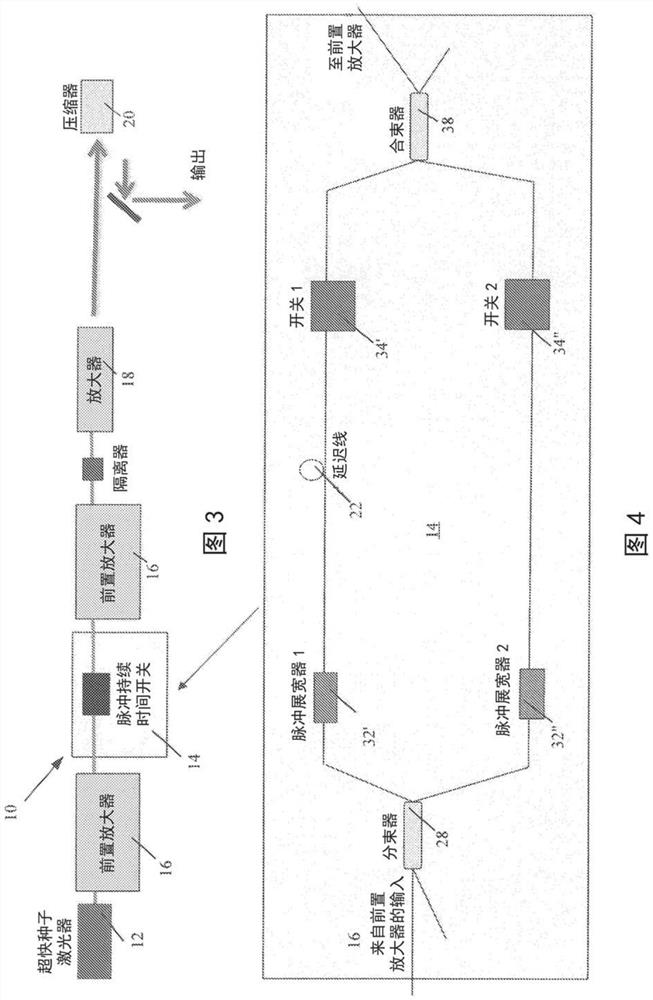

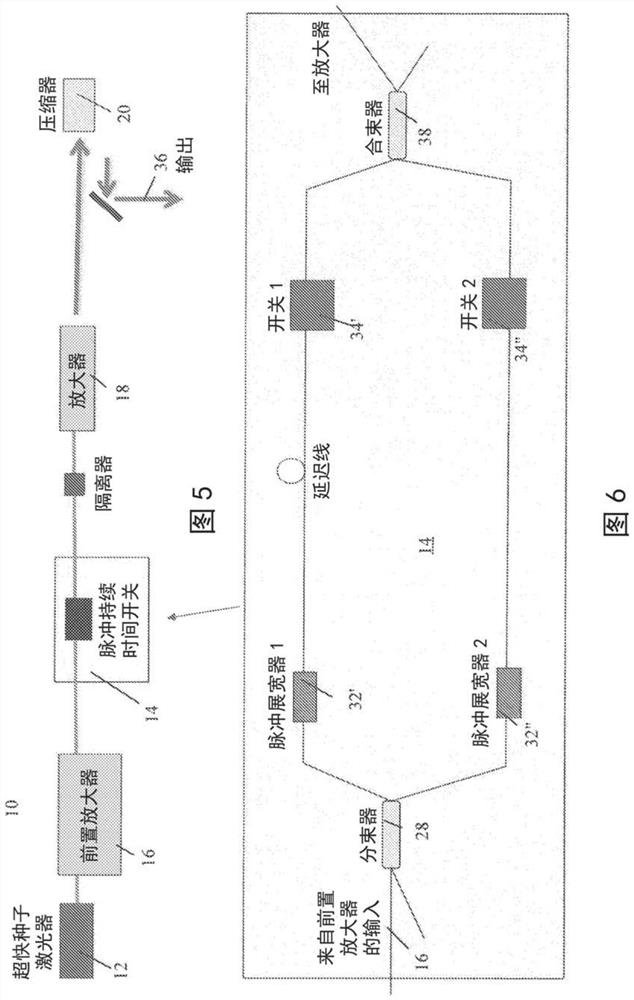

[0043] In the drawings, each identical or nearly identical component that is illustrated in various figures is represented by a like numeral. For purposes of clarity, not every component may be labeled in every drawing.

[0044] The laser system of the present invention is based on chirped pulse amplified laser technology and includes: a high speed pulse duration switch assembly operable to pass one or more copies of a pulse of desired duration while blocking or delaying other pulse durations Output. In the laser system of the present invention, proper dispersion management and optionally controllable adjustment of the spectral width of the dispersive elements (e.g., stretcher and compressor, hereinafter also referred to as upstream dispersive element and downstream dispersive element respectively) to set the pulse duration. Several schematic diagrams illustrating the inventive concept are discussed below.

[0045] refer to figure 1 , image 3 , Figure 5 , Figure 7 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com