Endoscope structure

An endoscope, hollow structure technology, applied in endoscopy, medical science, surgery and other directions, to achieve the effect of strong flexibility, good use requirements, and meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

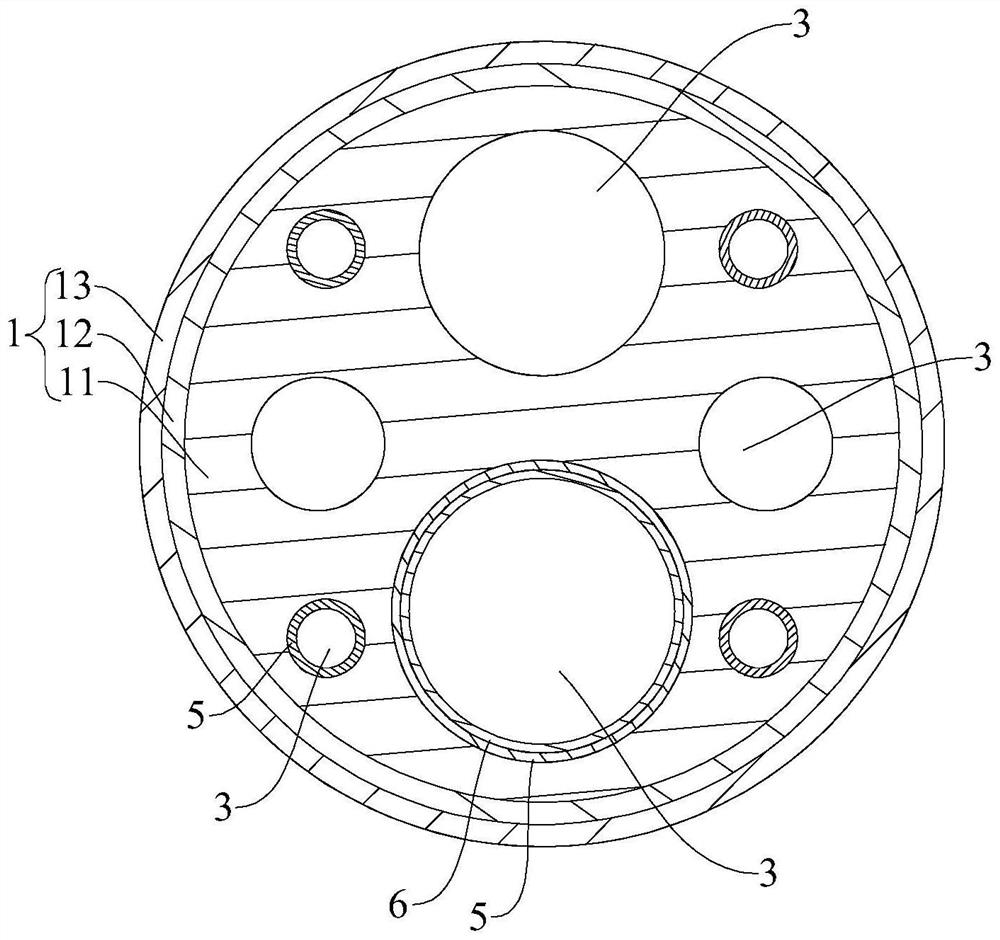

[0060] like Figure 1-Figure 2 As shown, the endoscope structure includes an operating part, a passive bending part 2 and an active bending part 1 connected in sequence. The operating part can drive the active bending part 1 to bend. The active bending part 1 includes a first body 11, a second An outer weaving 12 and a first sheath 13, the passive bending part 2 includes a second main body 21, a second outer weaving 22 and a second sheath 23 that are covered in sequence, and the first main body 11 and the second main body 21 are provided with eight working channel 3. Among the eight working channels 3 , four working channels 3 are provided with internal weaving 5 , and one working channel 3 is provided with internal weaving 5 and inner membrane 6 . The first body 11 and the second body 21 are made of the same material, and the rigidity of the first body 11 is smaller than that of the second body 21 .

Embodiment 2

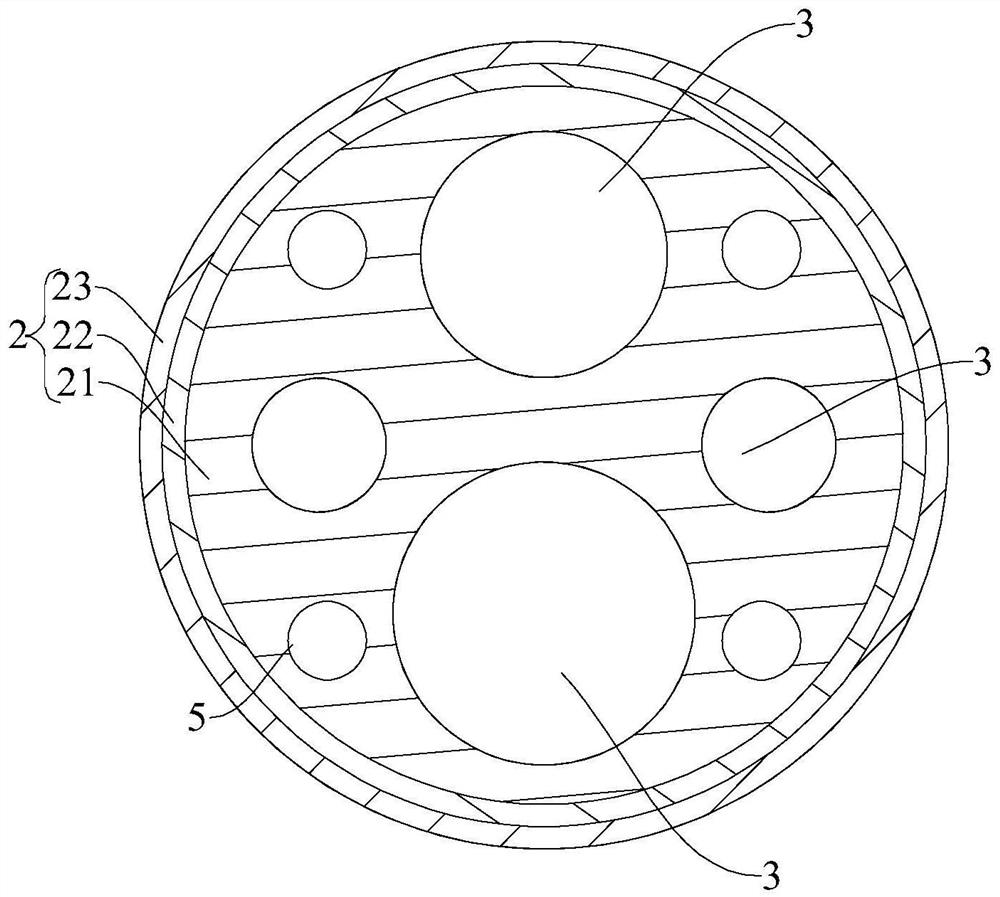

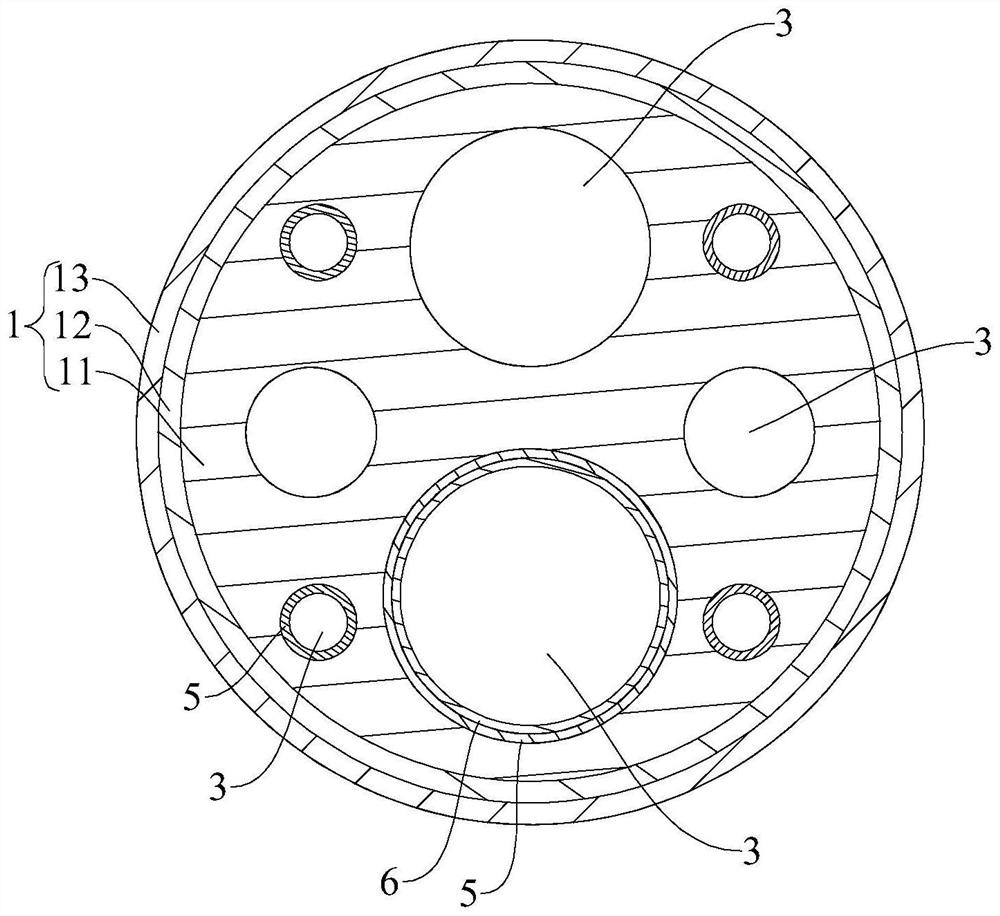

[0062] like Figure 3-Figure 5 As shown, the endoscope structure includes an operating part, a passive bending part 2 and an active bending part 1 connected in sequence. The operating part can drive the active bending part 1 to bend. The active bending part 1 includes a first body 11, a second An outer weaving 12 and a first sheath 13, the passive bending part 2 includes a second main body 21, a second outer weaving 22 and a second sheath 23 that are covered in sequence, and the first main body 11 and the second main body 21 are provided with eight working channel 3. Among the eight working channels 3 , four working channels 3 are provided with internal weaving 5 , and one working channel 3 is provided with internal weaving 5 and inner membrane 6 . A reinforcement channel 211 is provided in the second body 21 , and a reinforcement wire 4 is provided in the reinforcement channel 211 . like Figure 4 As shown, the first main body 11 is provided with an auxiliary channel 111 c...

Embodiment 3

[0064] like Figure 6-Figure 9 As shown, the endoscope structure includes an operating part, a passive bending part 2 and an active bending part 1 connected in sequence, the operating part can drive the active bending part 1 to bend, and the active bending part 1 includes a first main body 11, a second An outer weaving 12 and a first sheath 13, the passive bending part 2 includes a second main body 21, a second outer weaving 22 and a second sheath 23 that are covered in sequence, and the first main body 11 and the second main body 21 are provided with eight working channel 3. A hollow structure 112 is provided inside the first body 11 , and the hollow structure 112 is located in a solid area between a plurality of working channels 3 . The concrete structure of hollow structure 112 can be as follows Figure 6 or Figure 7 shown.

[0065] like Figure 8 As shown, in some special usage occasions, other areas of the working channel 3 can be completely cut off from the first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com