Water outlet valve

A water outlet valve and water outlet technology, applied in the direction of spraying devices, etc., can solve the problems of fluid energy loss, low cleaning efficiency, and single function, and achieve the effects of reducing pressure loss, reasonable design, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

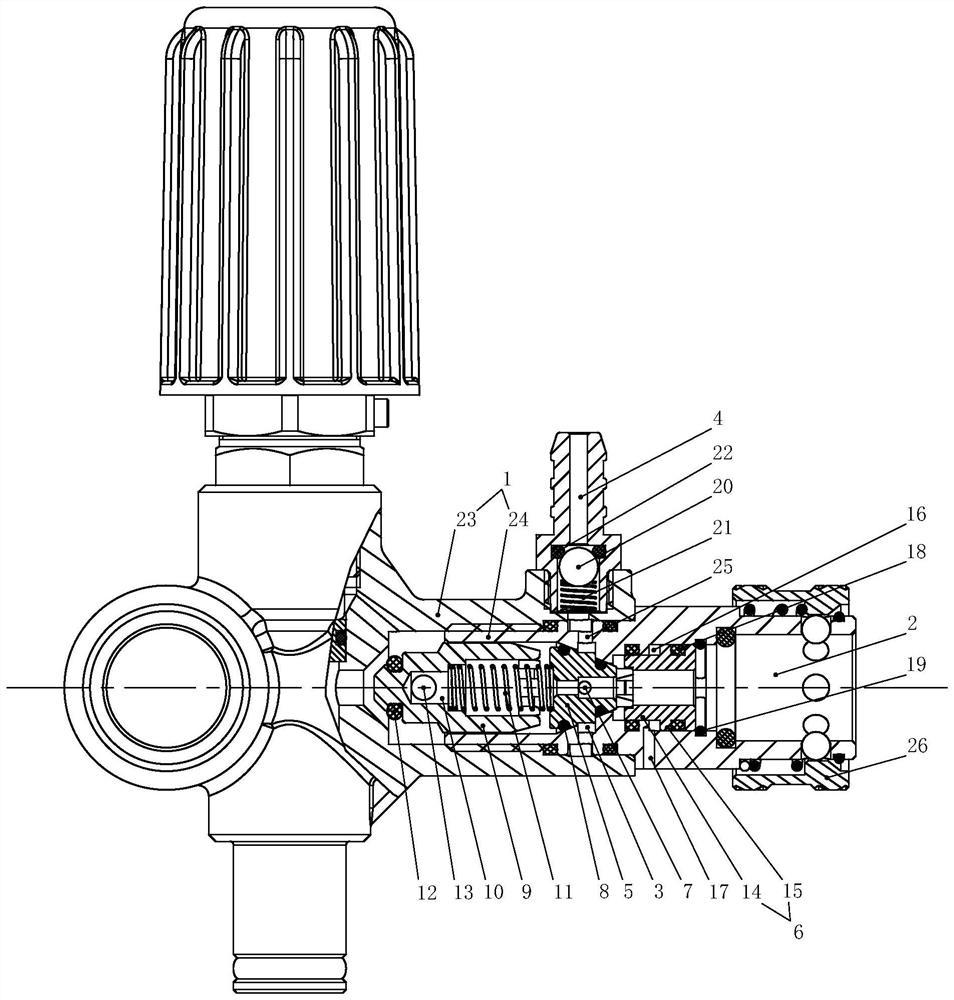

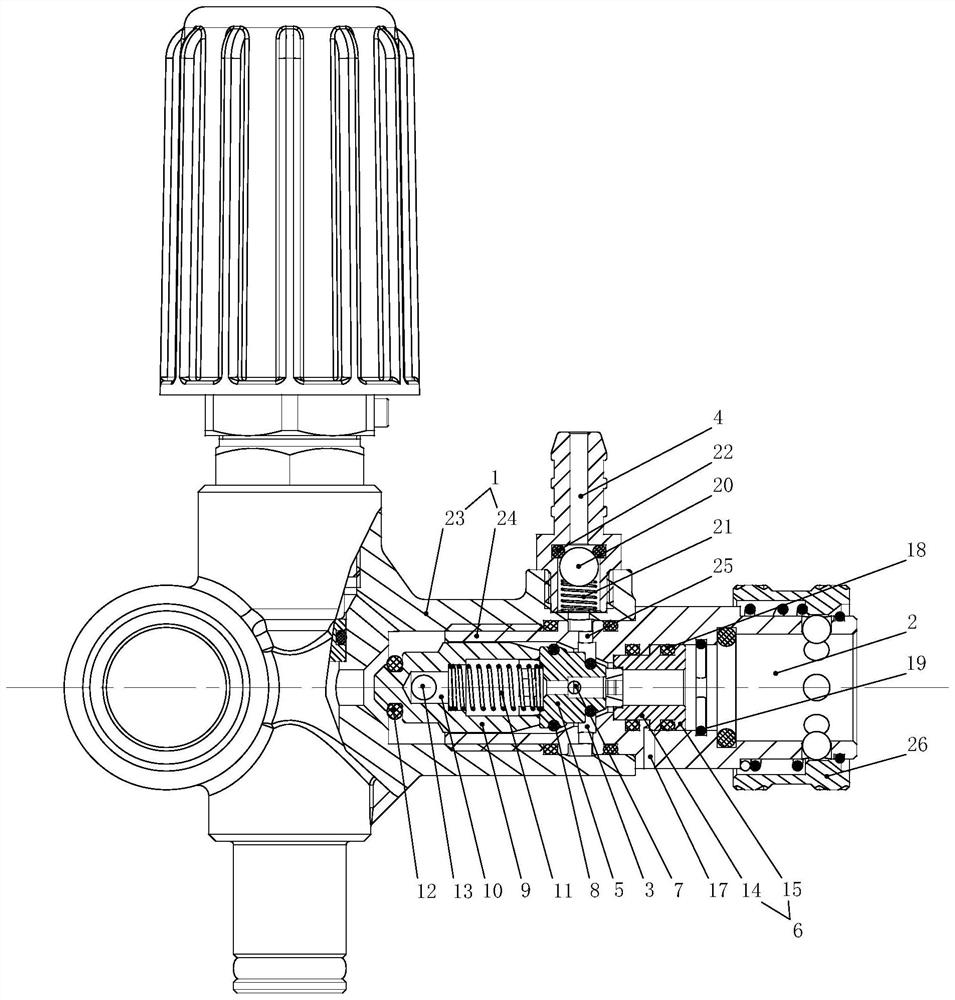

[0021] The present invention will be further described below with specific embodiment, see figure 1 -2:

[0022] A water outlet valve, comprising a valve body 1 with a water outlet hole 2, the water outlet hole 2 is provided with a limit ring surface, and an absorbent groove 3 is provided on the limit ring surface, and the valve body 1 is provided with an inner end and a The sorbent channel 4 connected to the sorbent groove 3 is provided with a one-way component that can prevent the liquid from flowing out, and the water outlet holes 2 located on the inner and outer sides of the limiting ring surface are respectively axially slidably connected with Venturi body 5, and the piston ring sleeve 6 whose inner end can abut against the Venturi body 5, the inner diameter of the inner hole of the Venturi body 5 is larger than the outer end, when the liquid in the outlet end of the water outlet hole 2 is low pressure, The Venturi body 5 slides outwards under the elastic force of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com